Busbar system

A busbar and segment technology, applied in the direction of engines, wind power generation, electrical components, etc., can solve problems such as thermal blockage, busbar component size and ventilation restrictions of the system, and achieve low cost, weight and material savings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

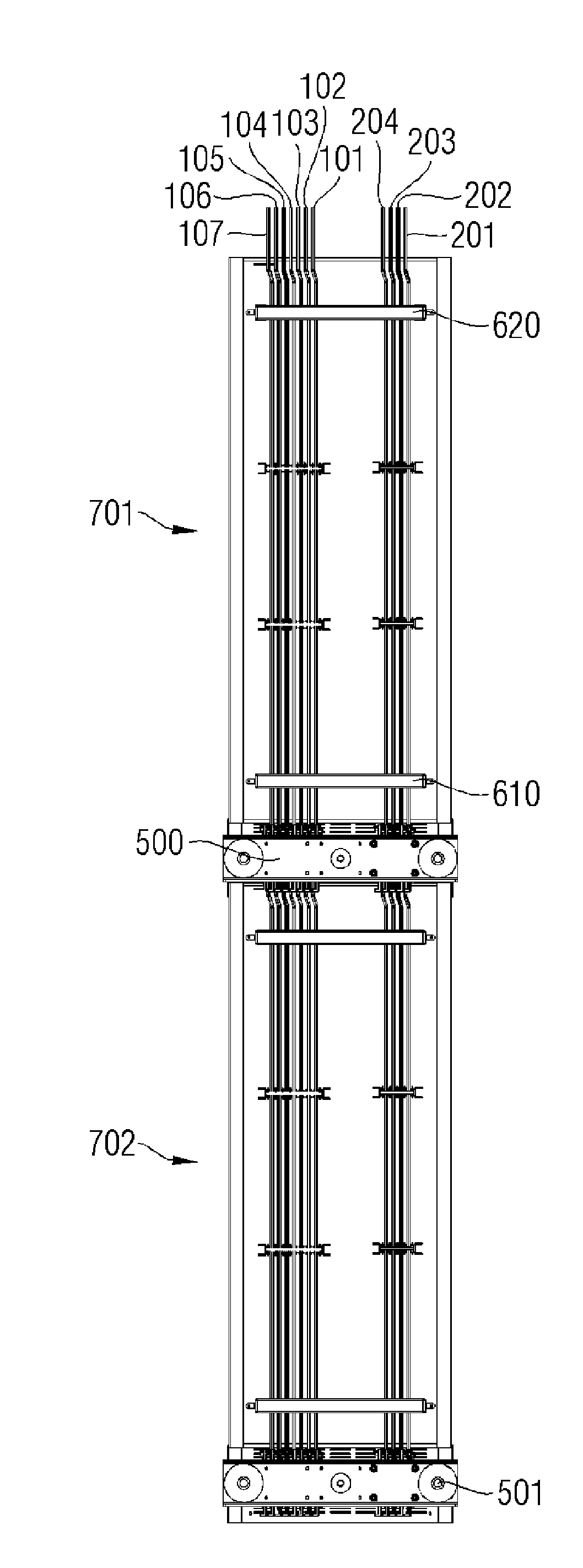

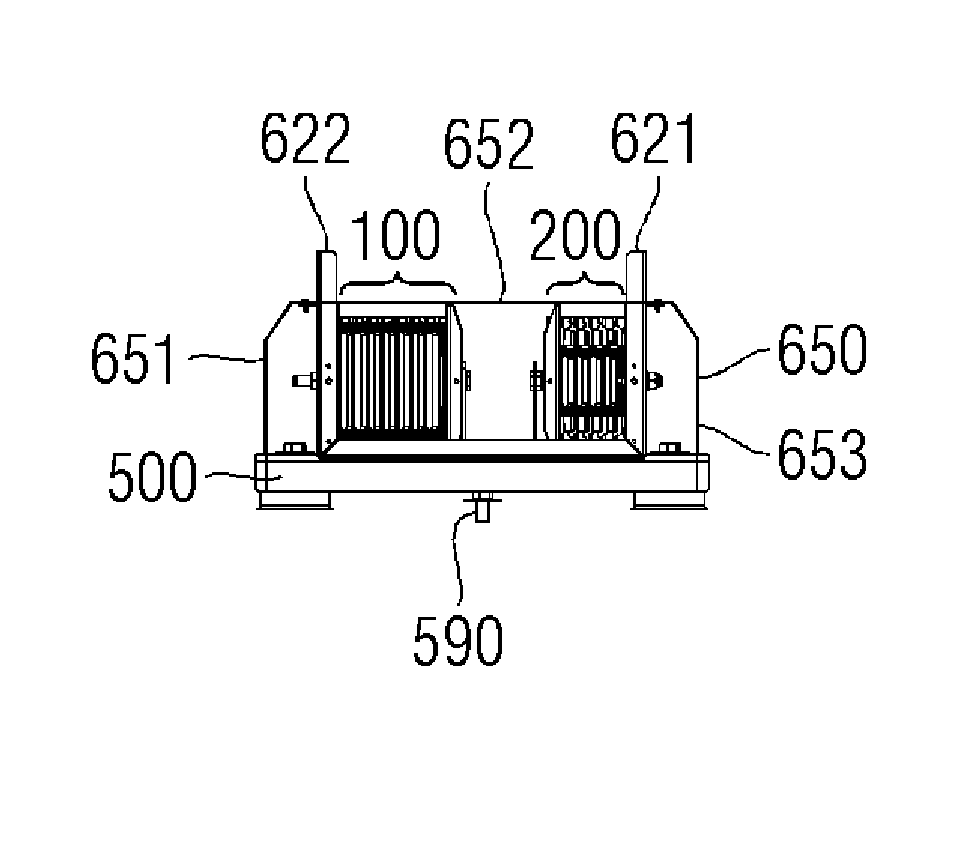

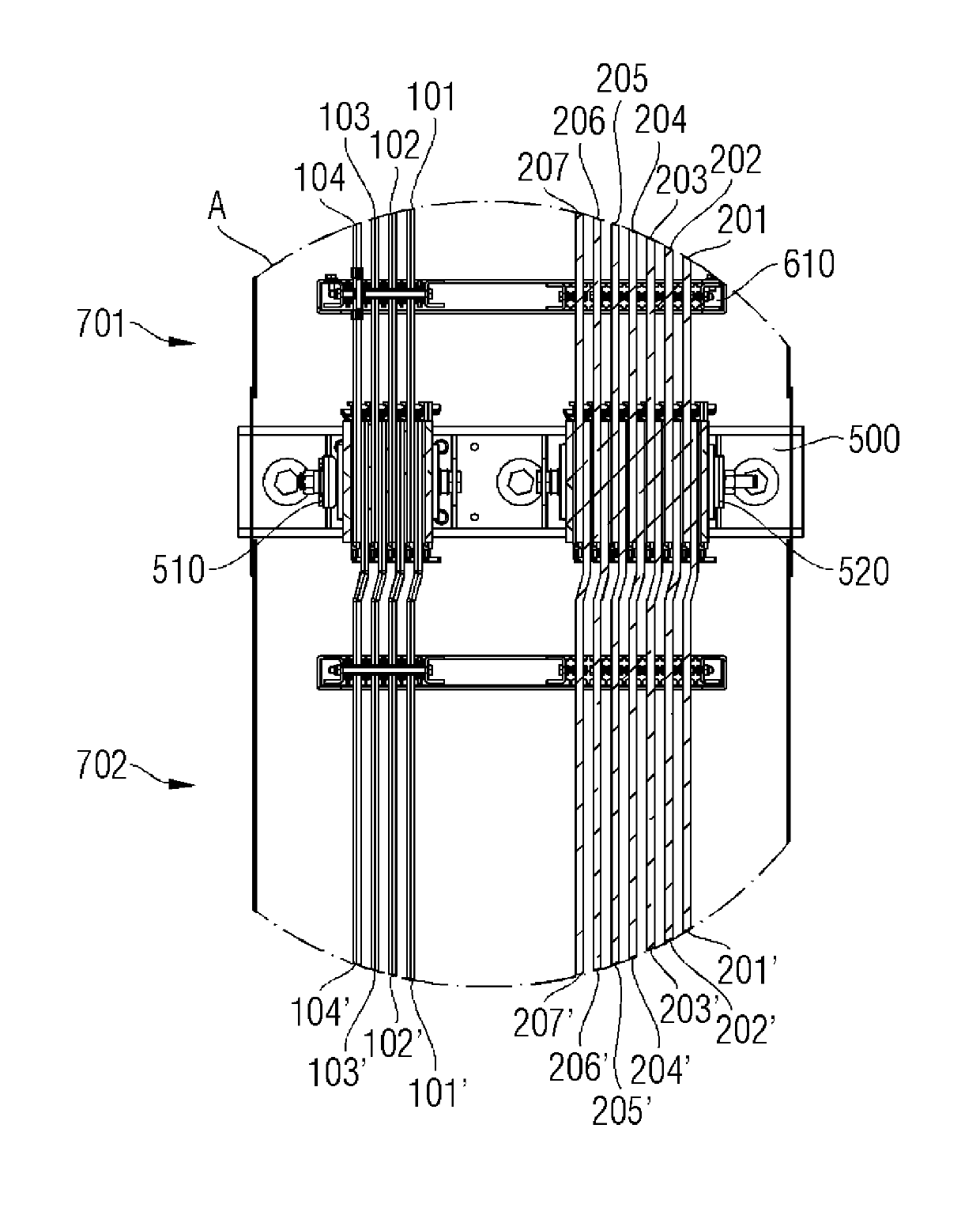

[0027] exist Figure 1A A busbar system for conveying electrical energy is shown in , which is shown in a first projection projected onto a plan view of the busbar system. The busbar system comprises a first segment 701 and a second segment 702 . The segments 701, 702 respectively include first bus bars 101, 102, 103, 104, 105, 106, 107 with a first cross-section and holders 500, 501, wherein the bus bars of each segment 701, 702 They are held by corresponding holders 500 , 501 and are electrically connected to each other through connection mechanisms 510 , 520 . according to Figure 1A , the holder 500 is assigned to the first segment 701 and the holder 501 is assigned to the second segment 702 . The connecting means 510, 520 connect the respective first bus bars 101, 102, 103, 104, 105, 106, 107 of the first and second segments.

[0028] The busbars of the busbar system according to the invention are elongated in the direction of current flow. according to Figure 1A , wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com