Composite power supply rail and method for producing the same

A composite power supply and manufacturing method technology, applied in the direction of power rails, chemical instruments and methods, lamination devices, etc., can solve the problems of increased difficulty in controlling the roll pass, complex production process, complex structure, etc., to achieve the promotion of current carrying and The effects of current transmission capability, simplified design structure, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

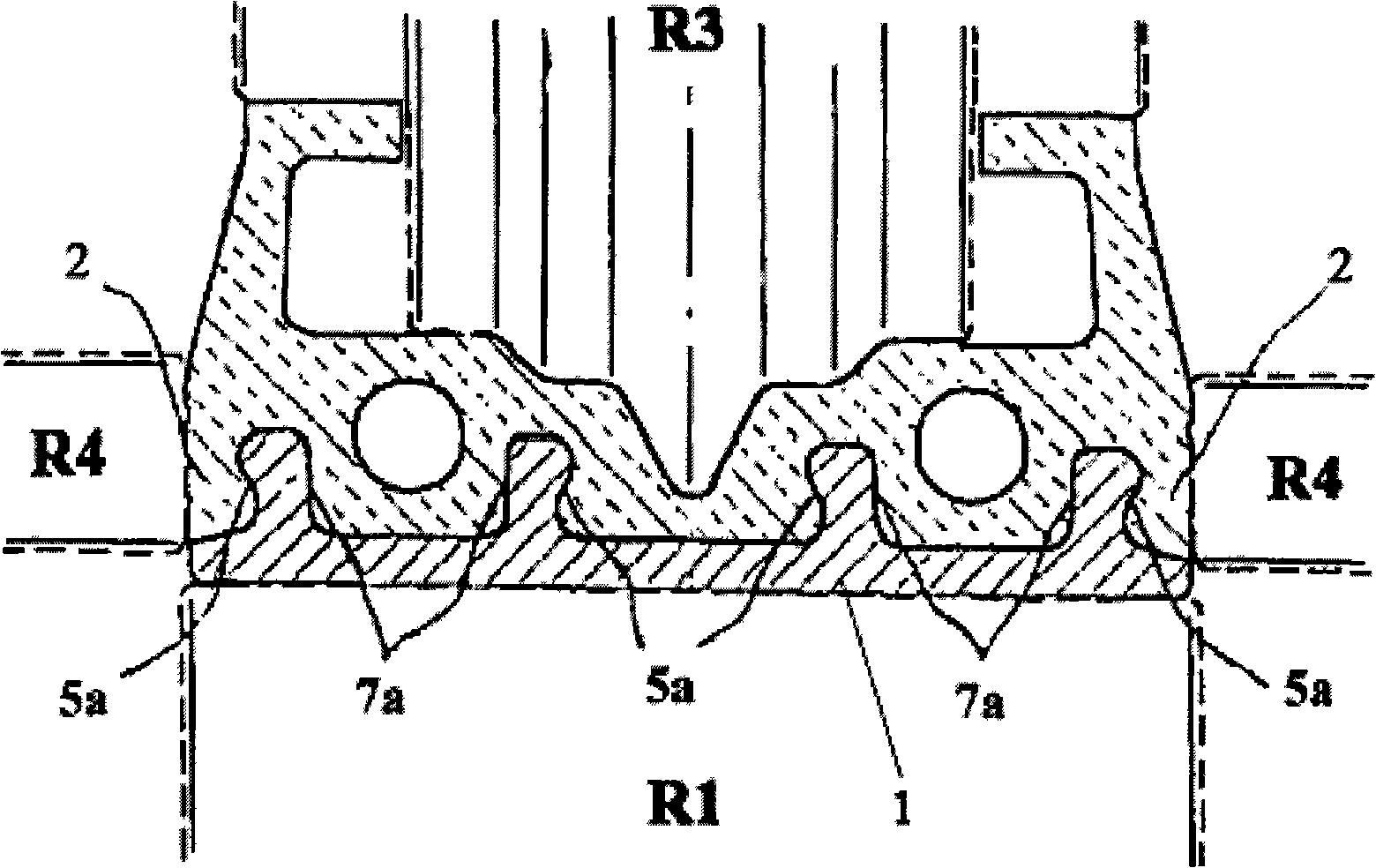

[0043] Such as Image 6 As shown, the geometry design of the current-carrying substrate 2 of the power supply rail considers the structure installed with the line track beam and the insulator, and forms a π shape with an ear 23 as a bolted body. Bolt fixing holes 22 can be drilled on the ear 23 according to the fixed position on the line track beam.

[0044] The geometry of the aluminum (alloy) extrusion profile as the base material should take into account the amount of metal deformation required for fastening the dovetail groove on the bimetal composite surface, such as Figure 7 As shown, bosses 21 and flat surfaces 24 are formed on the combined surface of the base material. as Figure 4 The shape of the boss 11 shown should also show the geometry of the metal deformation of the edge of the boss 21 to form a dovetail groove on the bimetallic composite surface of the aluminum profile. Same deal. However, when the dovetail fastening structure is formed, it depends on the ...

Embodiment 2

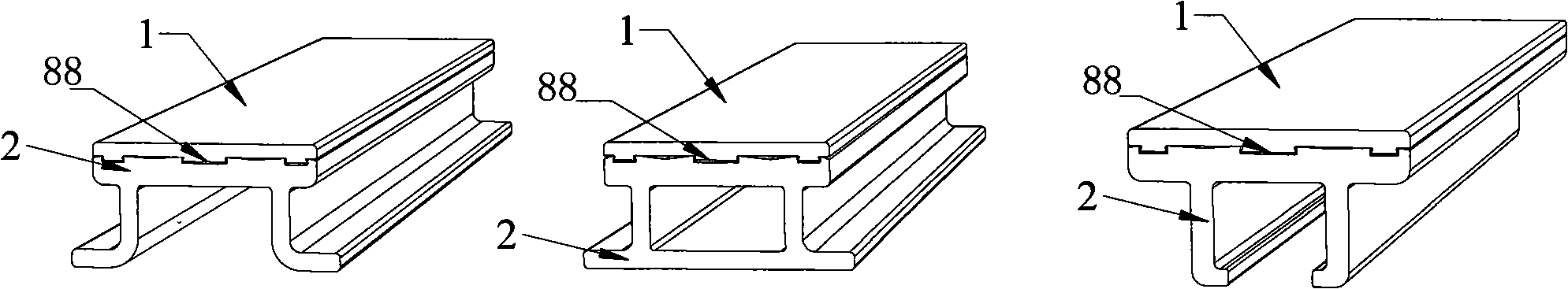

[0048] Such as Figure 9 As shown, the geometric shape of the composite surface of the hard wear-resistant / conductive contact body 1 and the aluminum (alloy) extruded profile matrix 2 is retained, and the geometric shape of the other side of the matrix is changed to a square hole structure with ears. There are screw holes to accommodate installation needs on line track beams. The same production process as in Example 1 is used to fasten the bimetal composite surface, and the ear bolts of aluminum profiles are used to fix the power supply rail with large current and wide contact surface.

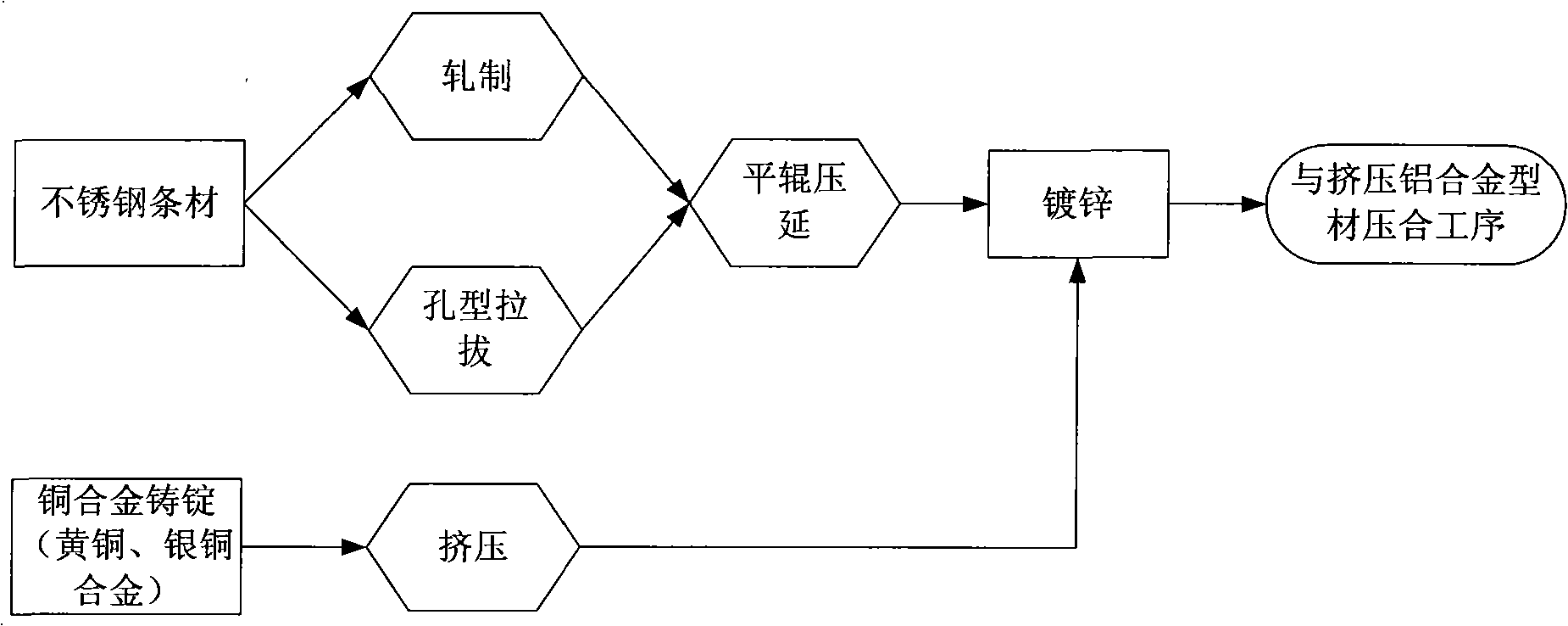

[0049] Also carry out alkali cleaning on the composite surface of the aluminum profile, partially remove the oxide layer and then galvanize to improve the adhesive strength of the composite surface, and also galvanize the contact surface of the hard wear-resistant / conductive contact metal contact body 1 . The carrier fluid of this embodiment---the geometric shape of aluminum (alloy) extrud...

Embodiment 3

[0051] Such as Figure 11 As shown, the composite surface structure of the dovetail fastening of the hard wear-resistant / conductive contact body 1 and the aluminum (alloy) extruded profile matrix 2 is retained, and the shape of the aluminum (alloy) profile matrix is changed to a geometry with a C-shaped groove. Shape, use the C-shaped slot to fix the power supply rail with a pressure plate. Using the same production process as in Example 1 to fasten the bimetallic composite, and use the C-shaped groove 25 on the aluminum (alloy) profile base 2 and the pressing plate 2b to fix it on the insulator of the line track beam.

[0052] For the composite surface of aluminum (alloy) profiles, the same alkali cleaning treatment method as in Example 1 should be taken, but local alkali cleaning (only on the composite surface) is allowed to promote the bimetallic composite adhesion strength.

[0053] The geometry of the aluminum (alloy) extruded profile substrate of the present embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com