Preparation method of multi-layer flexible printed circuit

A flexible circuit board and flexible circuit technology, which is applied in the direction of multi-layer circuit manufacturing, flexible printed circuit board, printed circuit manufacturing, etc. and other problems, to achieve the effect of easy large-scale implementation, low production equipment requirements, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0075] Another aspect of the embodiment of the present application provides a method for preparing a multi-layer flexible circuit board comprising:

[0076] 1) providing a flexible substrate, the flexible substrate comprising a first surface and a second surface opposite to the first surface;

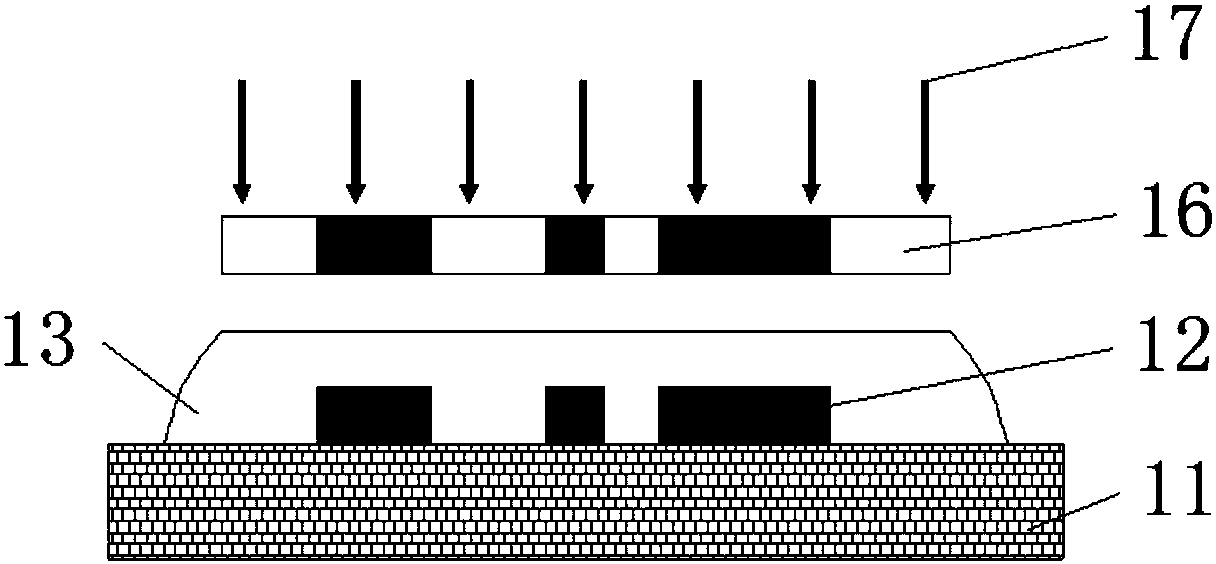

[0077] 2) setting a circuit layer as the first circuit layer on the first surface of the flexible substrate;

[0078] 3) setting an insulating medium layer as the first insulating medium layer on the circuit layer;

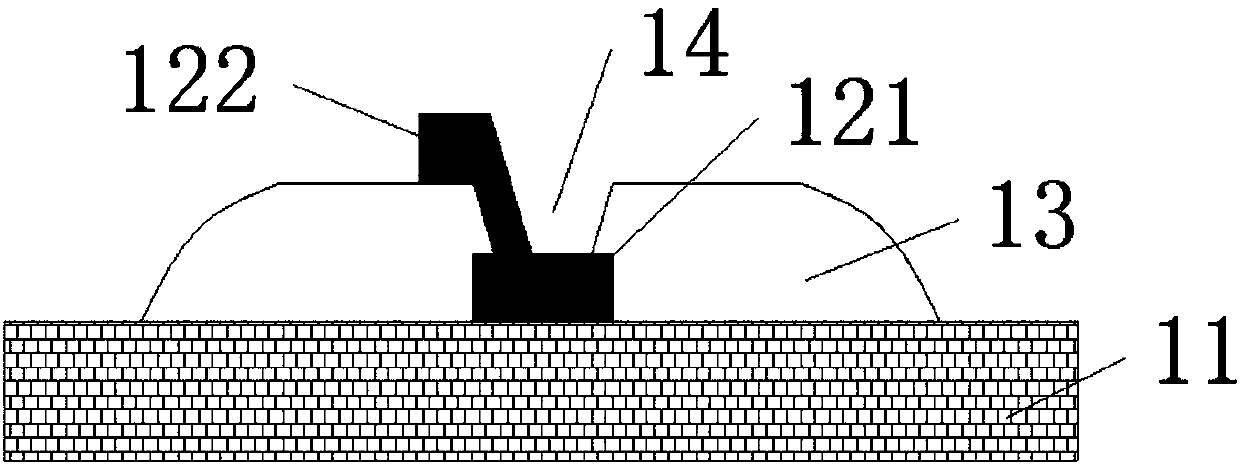

[0079] 4) Processing and forming at least one through hole on the insulating dielectric layer, the openings at both ends of the through hole are respectively arranged on the side surface of the insulating dielectric layer opposite to the first surface and the insulating dielectric layer and the first surface. the surface on the opposite side of the surface;

[0080] 5) Coating conductive paste or conductive ink on the insulating medium layer, and allowing a part of the co...

Embodiment 1

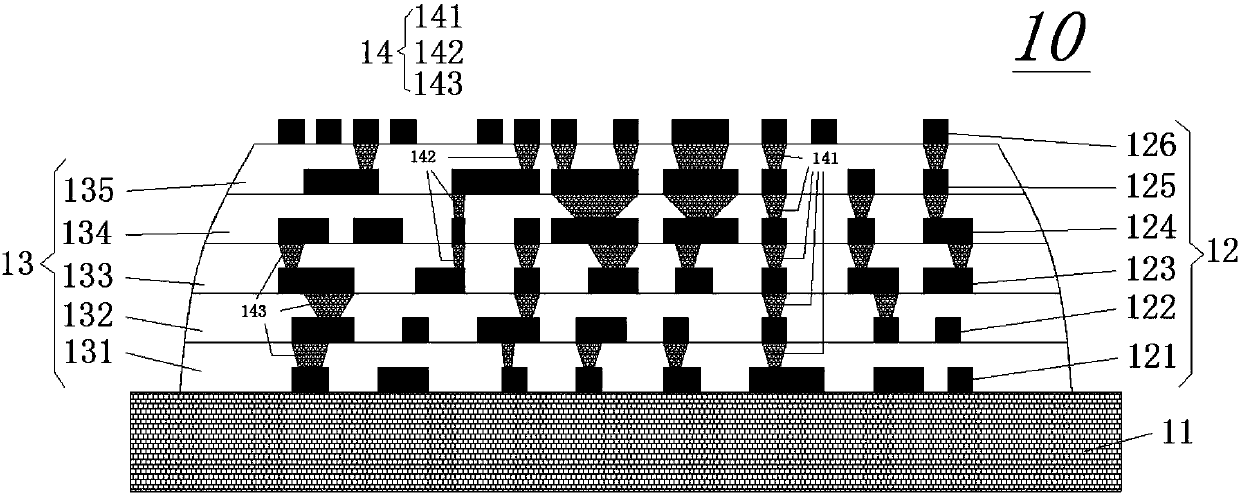

[0161] The multilayer flexible circuit board of this embodiment includes a flexible PET film as a base and a flexible circuit layer arranged on the PET film, and the flexible circuit layer includes a first circuit layer formed on the surface of the PET film, a first Insulating medium layer, second circuit layer, second insulating medium layer, third circuit layer, third insulating medium layer and fourth circuit layer (ie top circuit layer). The flexible circuit layer is also provided with conductive holes prepared by the aforementioned "plug plate" process, and the conductive holes include conductive through-holes that run through the entire flexible circuit layer, and conductive holes that connect the surface circuit layer and the internal circuit layer. Blind holes, conductive buried holes connecting internal circuit layers, etc.

[0162] The preparation process of the multilayer flexible circuit board in this embodiment may include: providing a flexible PET film, adopting ...

Embodiment 2

[0164] The multilayer flexible circuit board of this embodiment includes a flexible PET film as a base and a flexible circuit layer arranged on the PET film, and the flexible circuit layer includes a first circuit layer formed on the surface of the PET film, a first Insulating medium layer, second circuit layer, second insulating medium layer, third circuit layer, third insulating medium layer and fourth circuit layer, fourth insulating medium layer, fifth circuit layer, Five insulating dielectric layers, the sixth circuit layer (that is, the top circuit layer). The flexible circuit layer is also provided with conductive holes prepared by the aforementioned "plug plate" process, and the conductive holes include conductive through-holes that run through the entire flexible circuit layer, and conductive holes that connect the surface circuit layer and the internal circuit layer. Blind holes, conductive buried holes connecting internal circuit layers, etc.

[0165] The preparati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com