A manually operated three-station mechanism

A manual operation, three-station technology, applied in the direction of air switch components, etc., can solve problems such as misoperation, abnormal opening and closing, failure to meet interlock requirements, and multi-combination electrical space, so as to achieve accurate movement and reduce the number of operating mechanisms , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

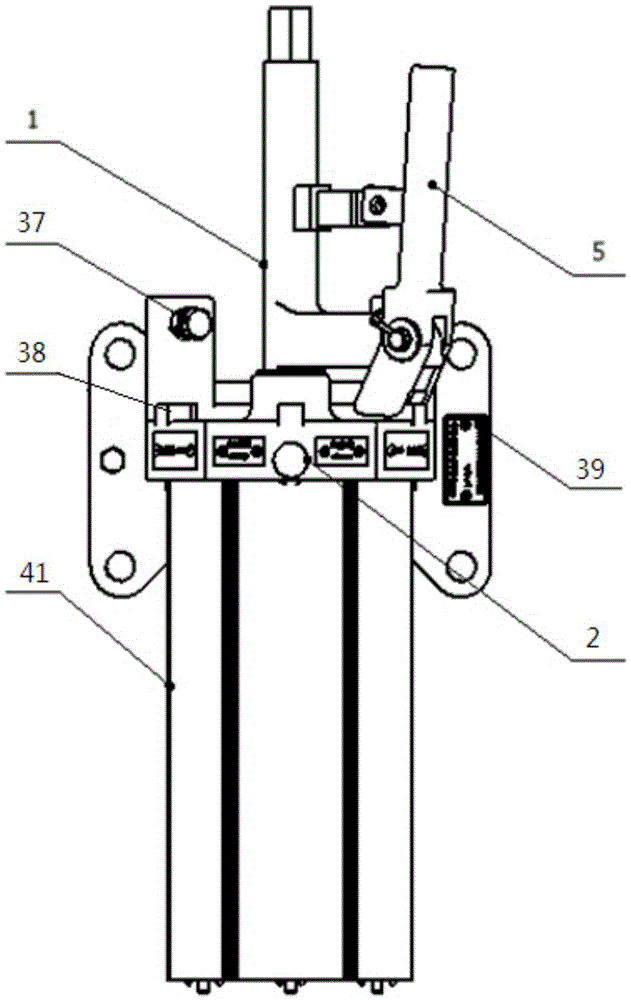

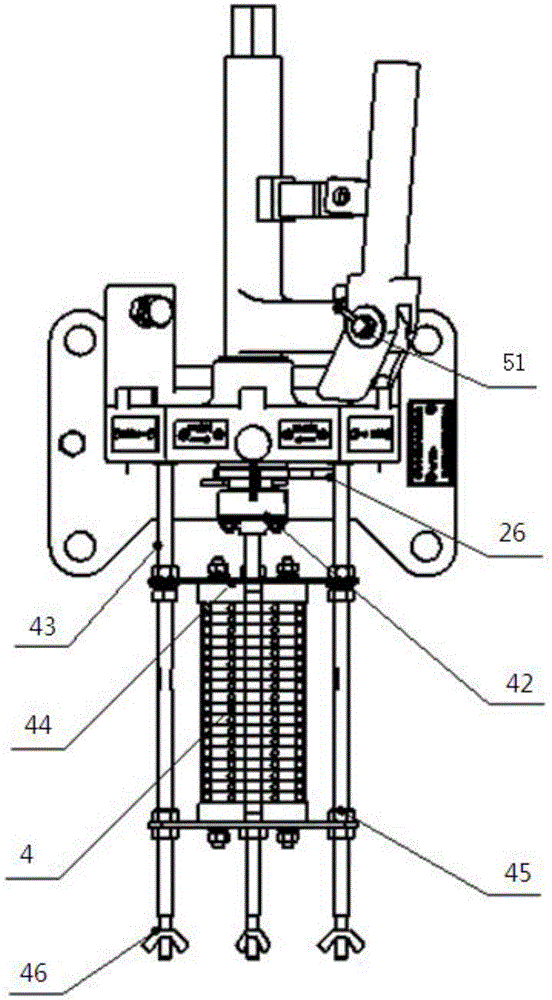

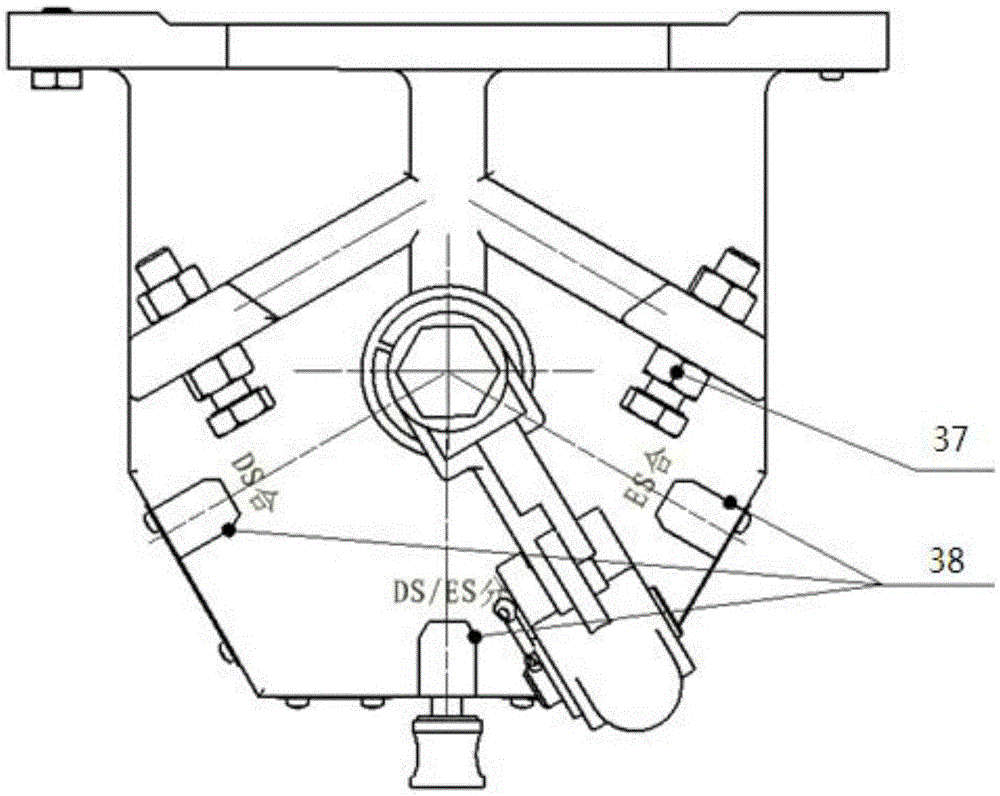

[0036] The present invention is a manual operation three-position mechanism, such as figure 1 As shown, it includes a support 3, an output shaft 1 that passes through the center hole on the support 3 and is rotatably connected, and a self-locking tripping device 2; image 3 As shown, the upper end surface of the support 3 is sequentially provided with three operating stations for isolation close (DS close), double break (DS / ES) and ground close (ES close), as Figure 5 As shown, the support 3 is provided with an annular groove on its lower end surface; the outer wall surface of the annular groove and the inner annular boss 31 are respectively provided with an installation through hole 33 and a limiting hole 32 in the radial direction; A limiting groove 34 is arranged on the outer wall surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com