A high-strength steel profile suitable for switch cabinets

A steel profile, high-strength technology, applied in substation/switch layout details, electrical components, substation/distribution device housing, etc., can solve problems such as rigidity, poor strength, inability to meet high-strength dynamic stability, and insufficient cabinet strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

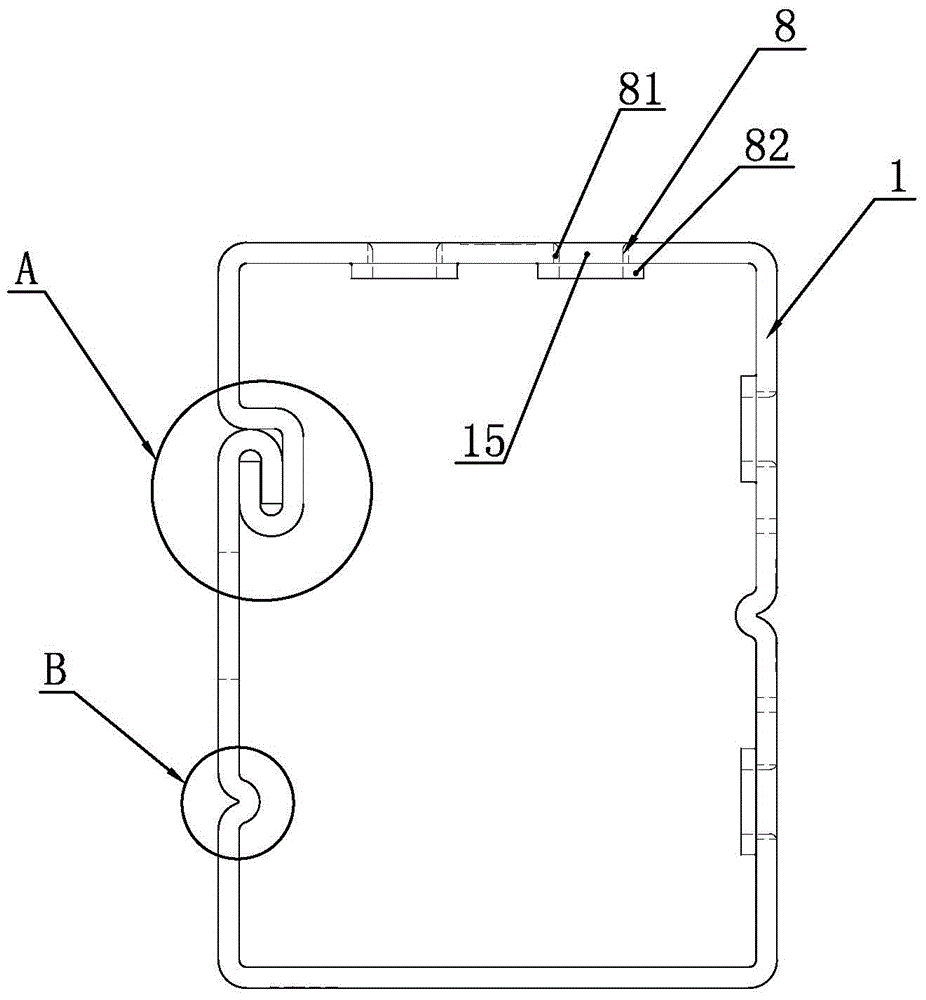

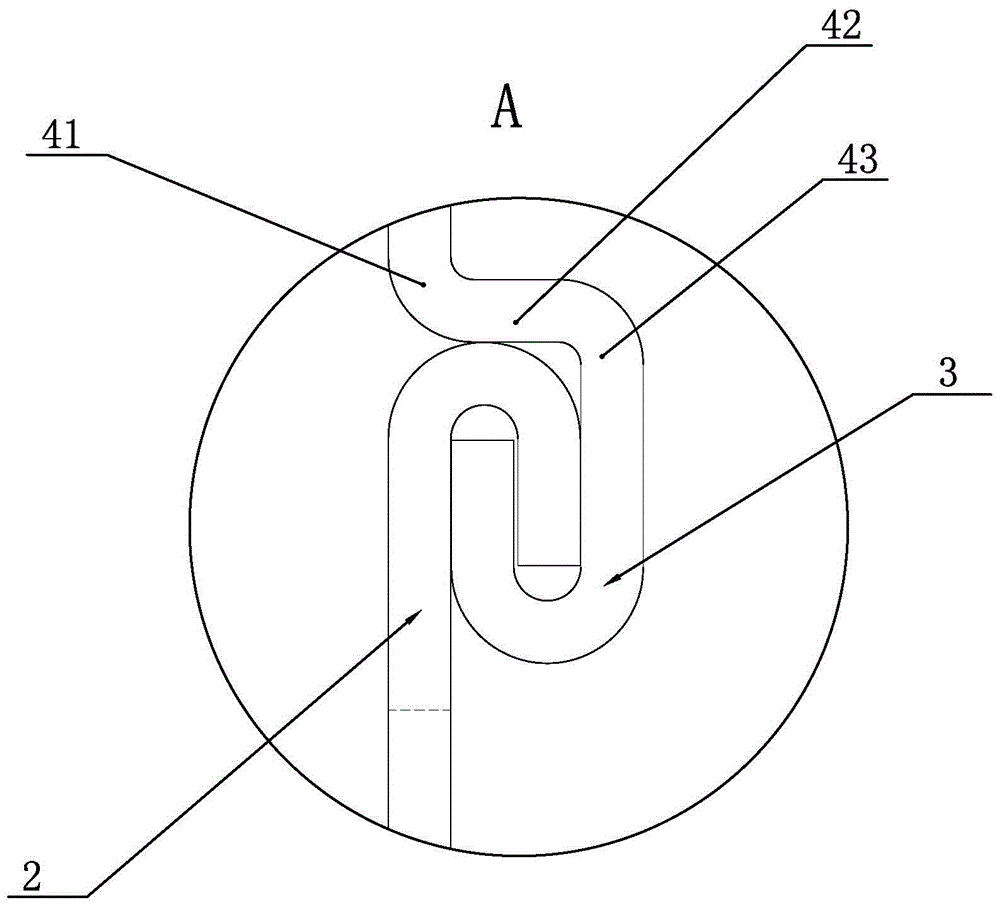

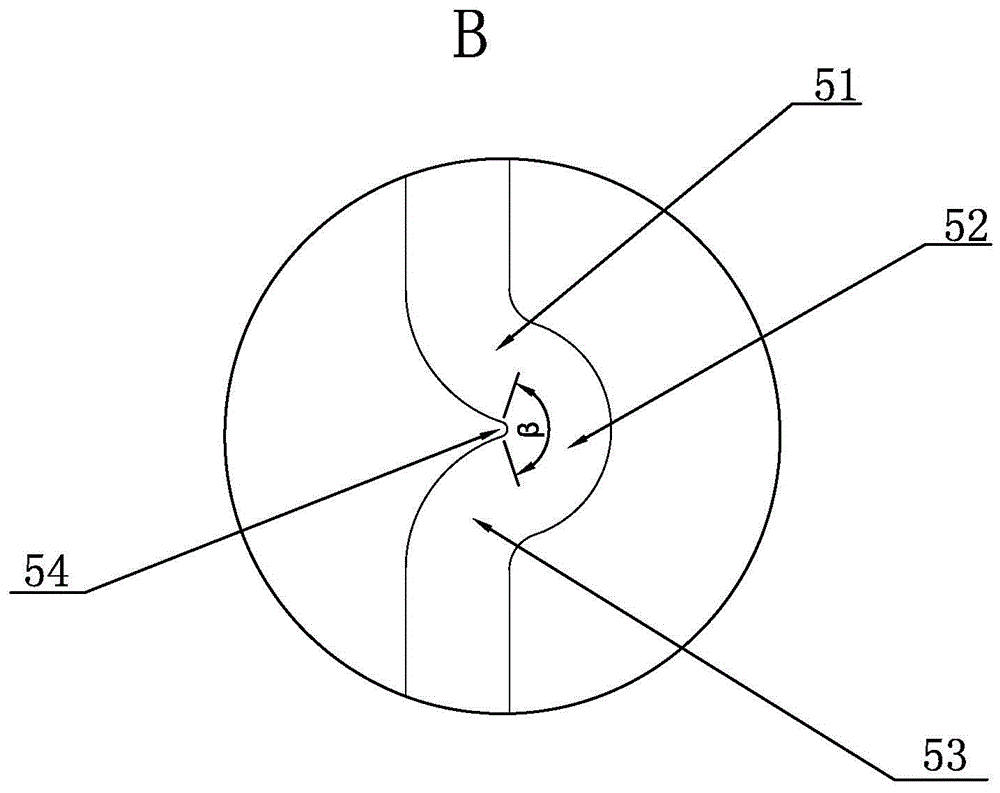

[0022] Such as figure 1 — Figure 5 As shown, the present invention discloses a high-strength steel profile suitable for switch cabinets, including a rectangular steel profile 1 formed by a steel plate rolling mill. The two U-shaped bending parts 3 are interlocked and formed, and several circular mounting holes 15 are arranged on the installation surface of the rectangular steel profile 1. In a specific embodiment of the present invention, the first U-shaped bending part 2 is provided with an anti-falling device, which includes a first arc-shaped part 41, a first conflicting part 42 and a second arc-shaped part 43 connected in sequence, and the first arc-shaped part 41 and the rectangular steel profile connection, the first conflicting part 42 is in conflict with the rear pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com