Nano oil-displacing agent for tertiary oil recovery and preparation method thereof

An oil-displacing agent, nanotechnology, applied in the field of nano-oil-displacing agent for tertiary oil recovery and its preparation, can solve the problems of high production cost of nano-emulsion, poor temperature and salt resistance, low efficiency of oil-displacing agent, etc. Oil efficiency, waste avoidance, effect on improving rock wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

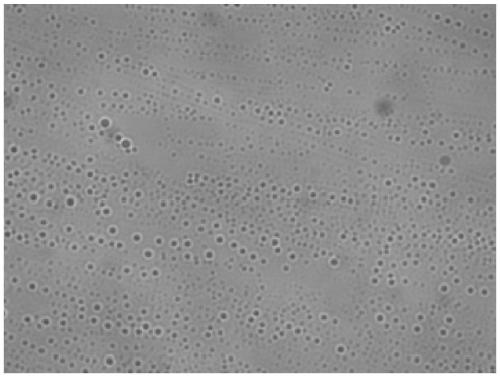

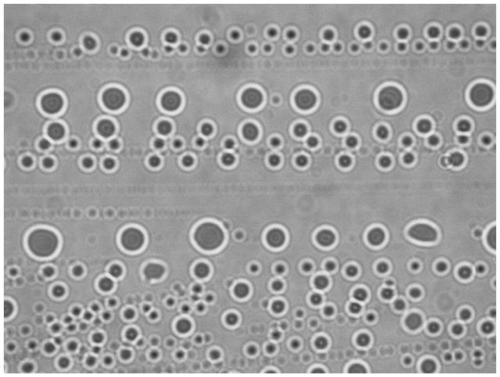

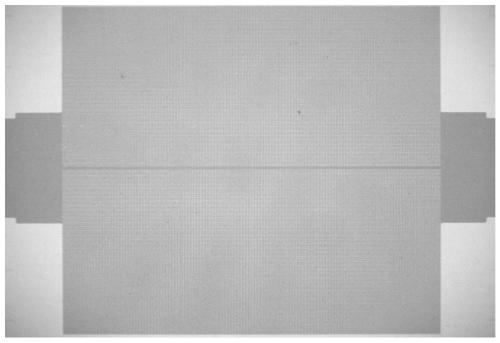

Image

Examples

Embodiment 1

[0037] A nano-oil displacement agent for tertiary oil recovery provided by a preferred embodiment of the present invention comprises the following components in parts by weight: 4.5 parts of oil phase (2.25 parts of white oil, 2.25 parts of liquid paraffin), 4.5 parts of anion-cation composite surface 0.4 part of active agent (0.32 part of cationic surfactant cetyltrimethylammonium bromide (CTAB), 0.08 part of anionic surfactant sodium dodecylbenzenesulfonate (SDBS)), co-surfactant (positive Butanol) 0.1 part, deionized water 95 parts.

[0038] Preparation of nano oil displacement agent by phase inversion composition method (PIC):

[0039] Add the cationic surfactant cetyltrimethylammonium bromide (CTAB) and the anionic surfactant sodium dodecylbenzenesulfonate (SDBS) into water to prepare an aqueous surfactant solution and heat it to 65°C; Heat 68# white oil, liquid paraffin, and co-surfactant n-butanol to 65°C in another reactor, and stir at 600rpm to form an oil mixture; a...

Embodiment 2

[0041] A nano-oil displacement agent for tertiary oil recovery provided by a preferred embodiment of the present invention comprises the following components in parts by weight: 4.5 parts of oil phase (2.25 parts of white oil, 2.25 parts of liquid paraffin), 4.5 parts of anion-cation composite surface 0.6 part of active agent (0.48 part of cationic surfactant cetyltrimethylammonium bromide (CTAB), 0.12 part of anionic surfactant sodium dodecylbenzenesulfonate (SDBS)), cosurfactant (positive Butanol) 0.1 part, deionized water 94.9 parts.

[0042] Preparation of nano oil displacement agent by phase inversion composition method (PIC):

[0043] Add the cationic surfactant cetyltrimethylammonium bromide (CTAB) and the anionic surfactant sodium dodecylbenzenesulfonate (SDBS) into water to prepare an aqueous surfactant solution and heat it to 65°C; Heat white oil, liquid paraffin, and co-surfactant n-butanol in another reactor to 65°C, and stir at 600rpm to form an oil mixture; add su...

Embodiment 3

[0045] A nano-oil displacement agent for tertiary oil recovery provided by a preferred embodiment of the present invention comprises the following components in parts by weight: 4.5 parts of oil phase (2.25 parts of white oil, 2.25 parts of liquid paraffin), 4.5 parts of anion-cation composite surface 0.8 part of active agent (0.64 part of cationic surfactant cetyltrimethylammonium bromide (CTAB), 0.16 part of anionic surfactant sodium dodecylbenzenesulfonate (SDBS)), co-surfactant (positive Butanol) 0.1 part, deionized water 94.6 parts.

[0046] Preparation of nano oil displacement agent by phase inversion composition method (PIC):

[0047] Add the cationic surfactant cetyltrimethylammonium bromide (CTAB) and the anionic surfactant sodium dodecylbenzenesulfonate (SDBS) into water to prepare an aqueous surfactant solution and heat it to 65°C; Heat white oil, liquid paraffin, and co-surfactant n-butanol in another reactor to 65°C, and stir at 600rpm to form an oil mixture; add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com