Direct current motor encoder connecting device

A connection device, DC motor technology, applied in the direction of electromechanical devices, structural connections, electrical components, etc., can solve the problems of many DC motor encoders, and achieve the effects of easy processing, good mechanical performance, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

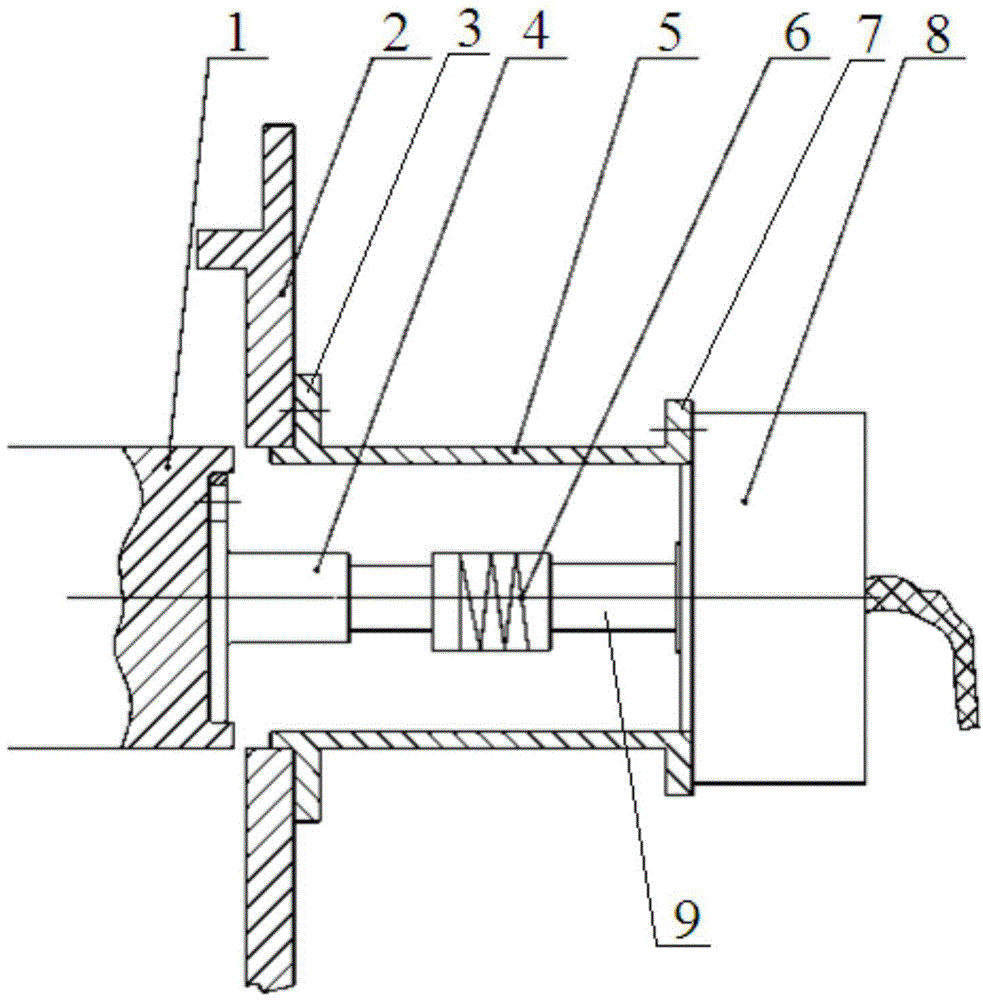

[0011] see figure 1 , a DC motor encoder connecting device, including a connecting shaft 4 and a connecting pipe 5, the front end of the connecting pipe 5 has a front mounting plate 3 connected with the outer cover 2 of the motor, and the rear end of the connecting pipe 5 has a connection with the encoder The rear mounting plate 7 connected with the shell 8, the connecting shaft 4 is located in the connecting pipe 5, the front end of the connecting shaft 4 is connected with the main shaft 1 of the motor, and the rear end of the connecting shaft 4 is connected with the main shaft 9 of the encoder through a soft connection 6 is connected.

[0012] In the present invention, an annular notch matching the outer profile of the motor cover 2 is formed between the front mounting plate 3 and the outer wall of the front end of the connecting pipe 5; The circular spigot matching the front profile of axis 4 has high concentricity and small circular runout.

[0013] The connecting shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com