Round screen printing plate machine of round concave wallpaper printer

A technology of printing machines and screen printing machines, applied in printing machines, rotary printing machines, screen printing machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

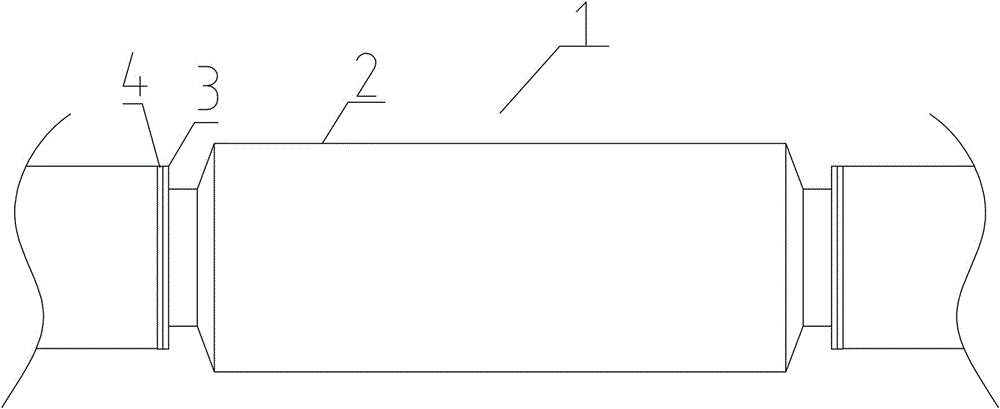

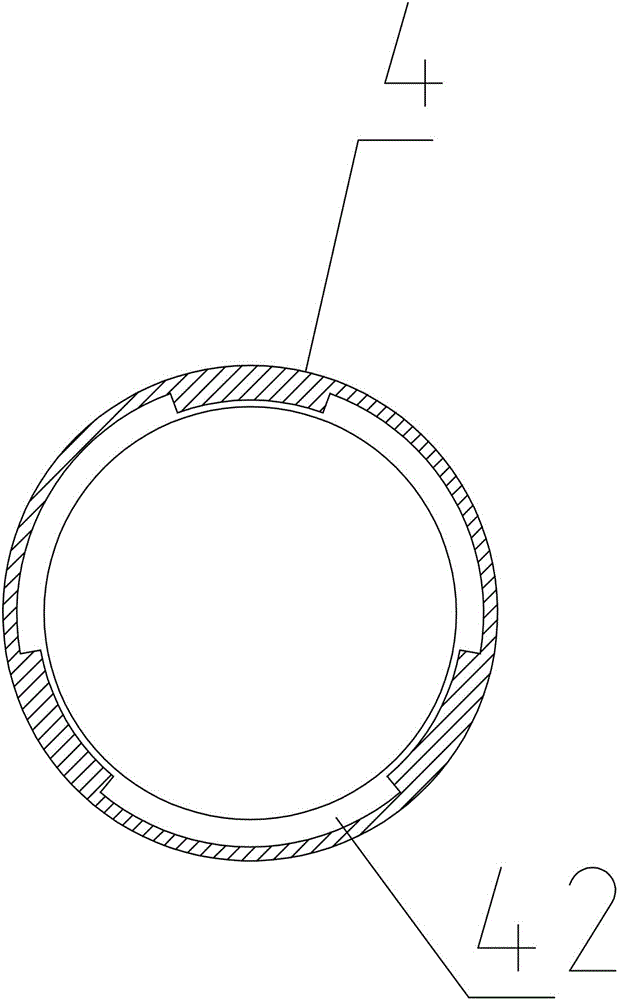

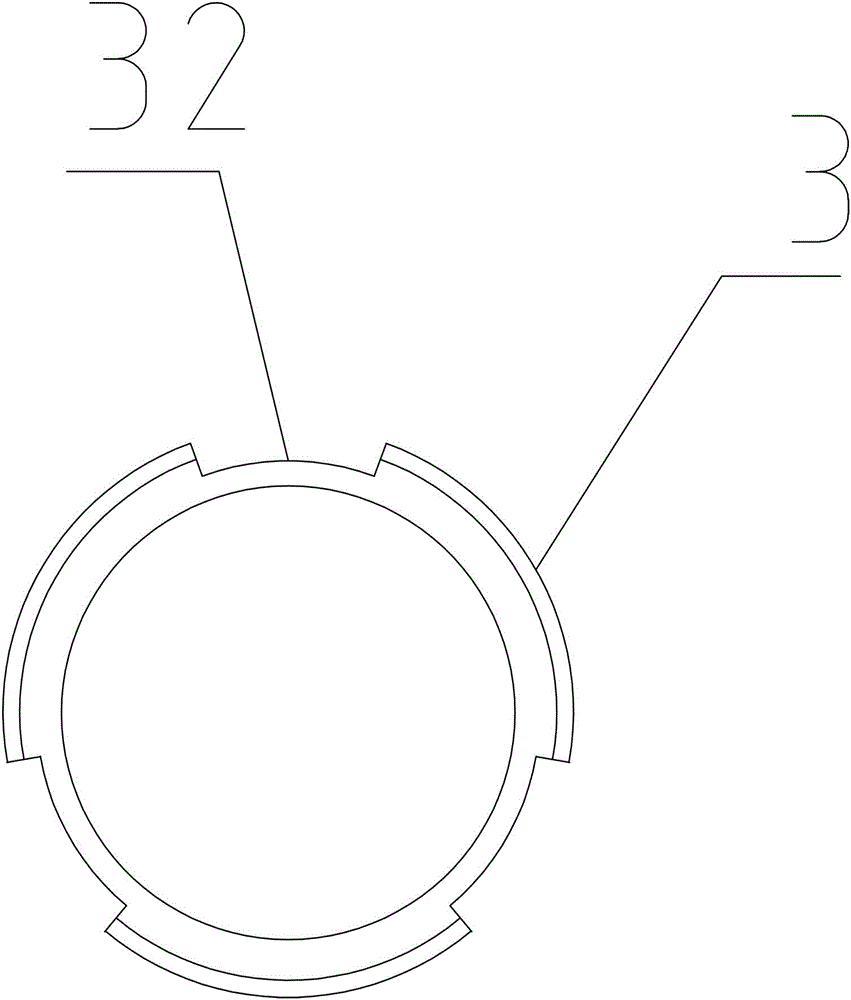

[0022] Such as figure 1 , 2 , 3, 4, a rotary screen machine of a circular concave wallpaper printing machine, the rotary screen machine includes a rotary screen drive device, a rotary screen version 1, and a device that connects the rotary screen drive device and the rotary screen version 1 Connecting device, the rotary screen version 1 includes a rotary screen version roll 2, and a rotary screen version seat 3 which is arranged at both ends of the rotary screen version roll 2. connection, the other side is provided with three evenly distributed protrusions 32; the connecting device includes a version seat collar 4, a locking device, the version seat collar 4 is a ring, one side is connected with the drive shaft of the rotary screen drive device, There are three evenly distributed grooves 42 on the inner wall of the collar 4 of the other panel seat, and the protrusions 32 and the grooves 42 overlap each other. The movable piece 7 is threaded, the fixed catch 6 and the movabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com