Patents

Literature

37 results about "Wallpaper printer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

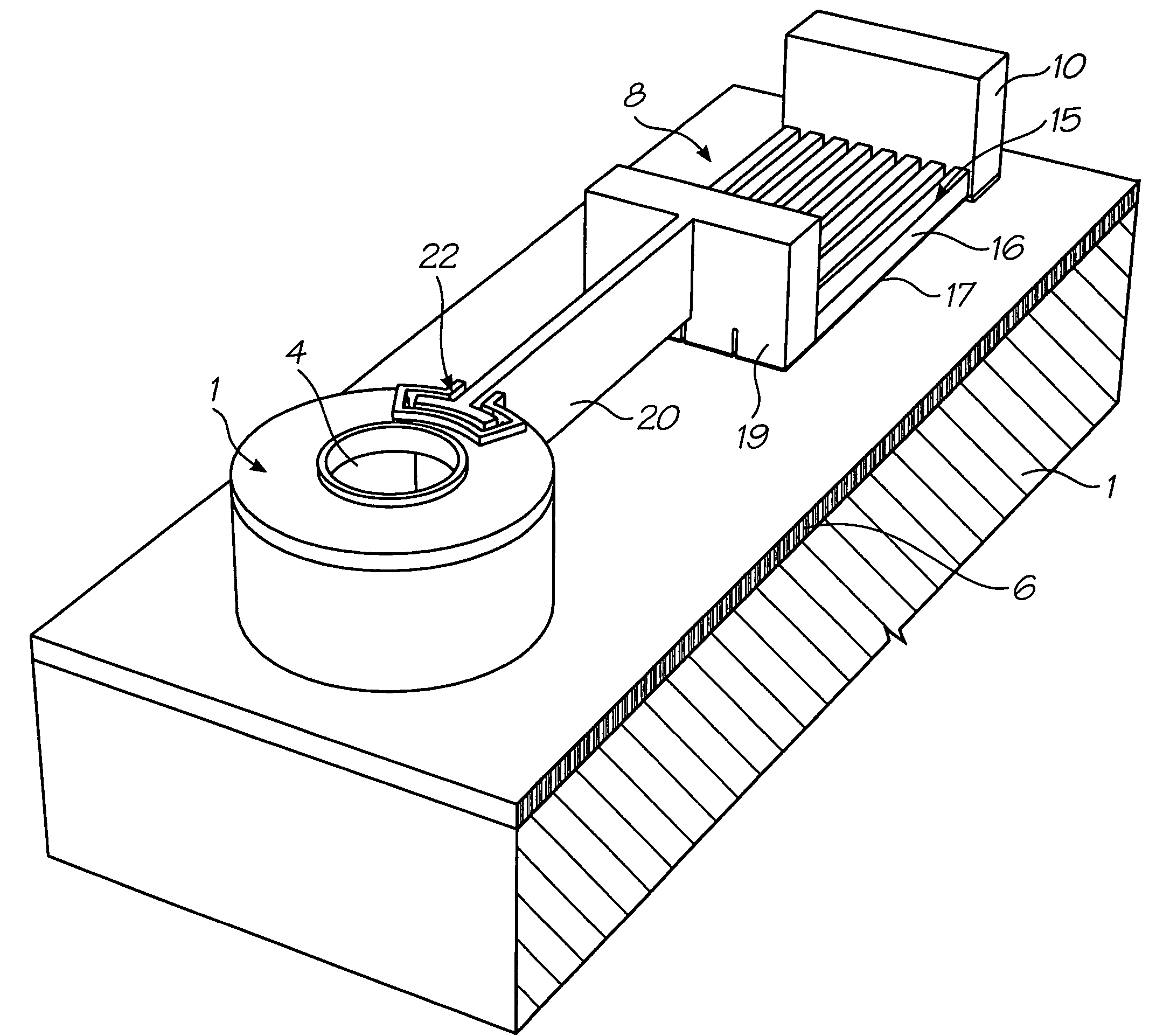

In-line dryer for a printer

ActiveUS6944970B2Eliminate stock-out, stock-control/ordering and stock obsolesces issuesEliminate inventoryTypewritersDrying machines with progressive movementsWallpaper printerEngineering

Owner:SILVERBROOK RES PTY LTD +1

Drying method for a printer

InactiveUS6920704B1Eliminate stock-out, stock-control/ordering and stock obsolesces issuesEliminate inventoryDrying using combination processesInking apparatusWallpaper printerEngineering

The invention provides a method for drying a web of media in a printer such as a wallpaper printer. The method includes the step of loading the web in a path that traverses a compartment in a dryer in the printer. The compartment has an opening across the top. The web is allowed to descend into the comparetent, as required, to lengthen the path.

Owner:SILVERBROOK RES PTY LTD +1

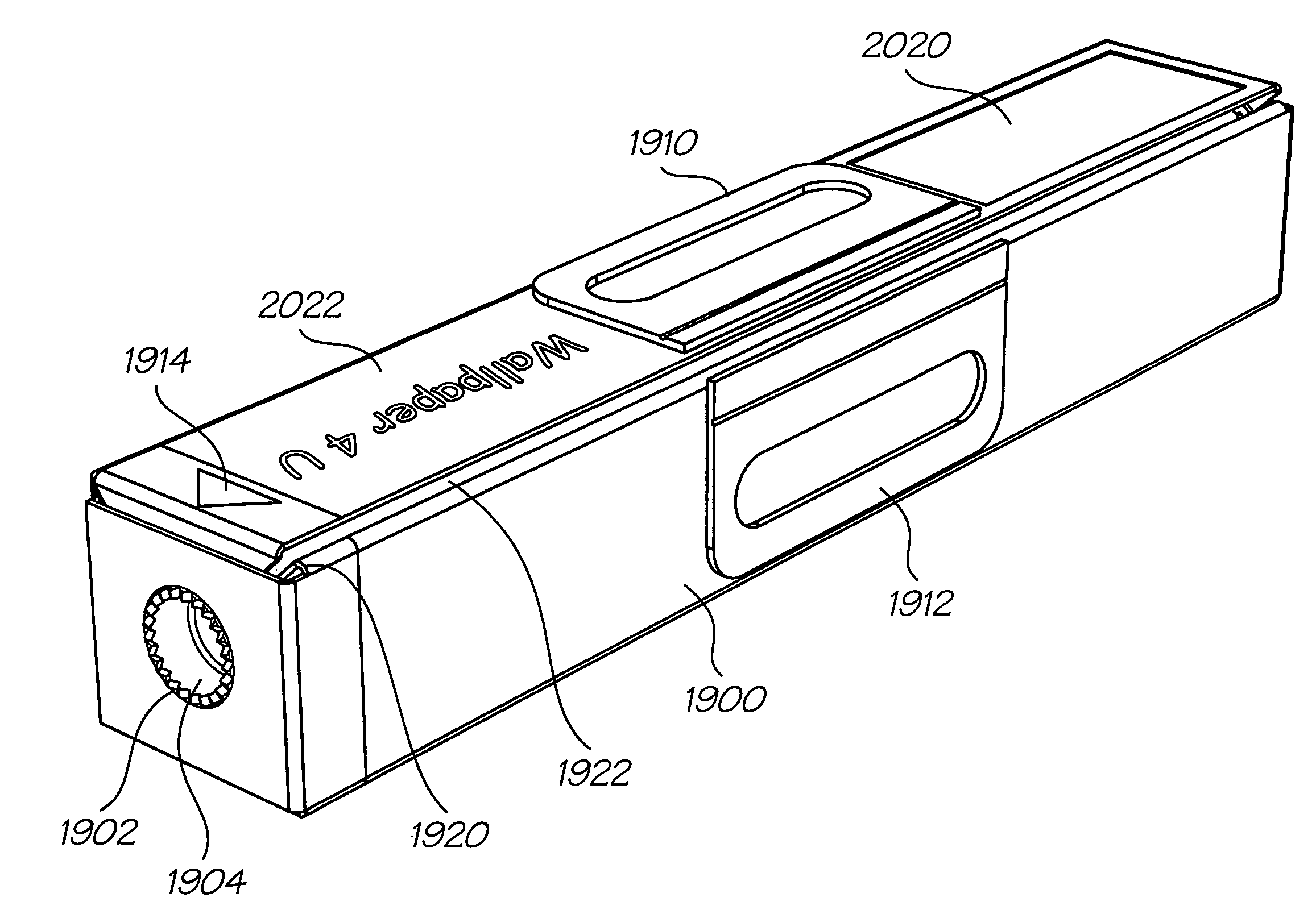

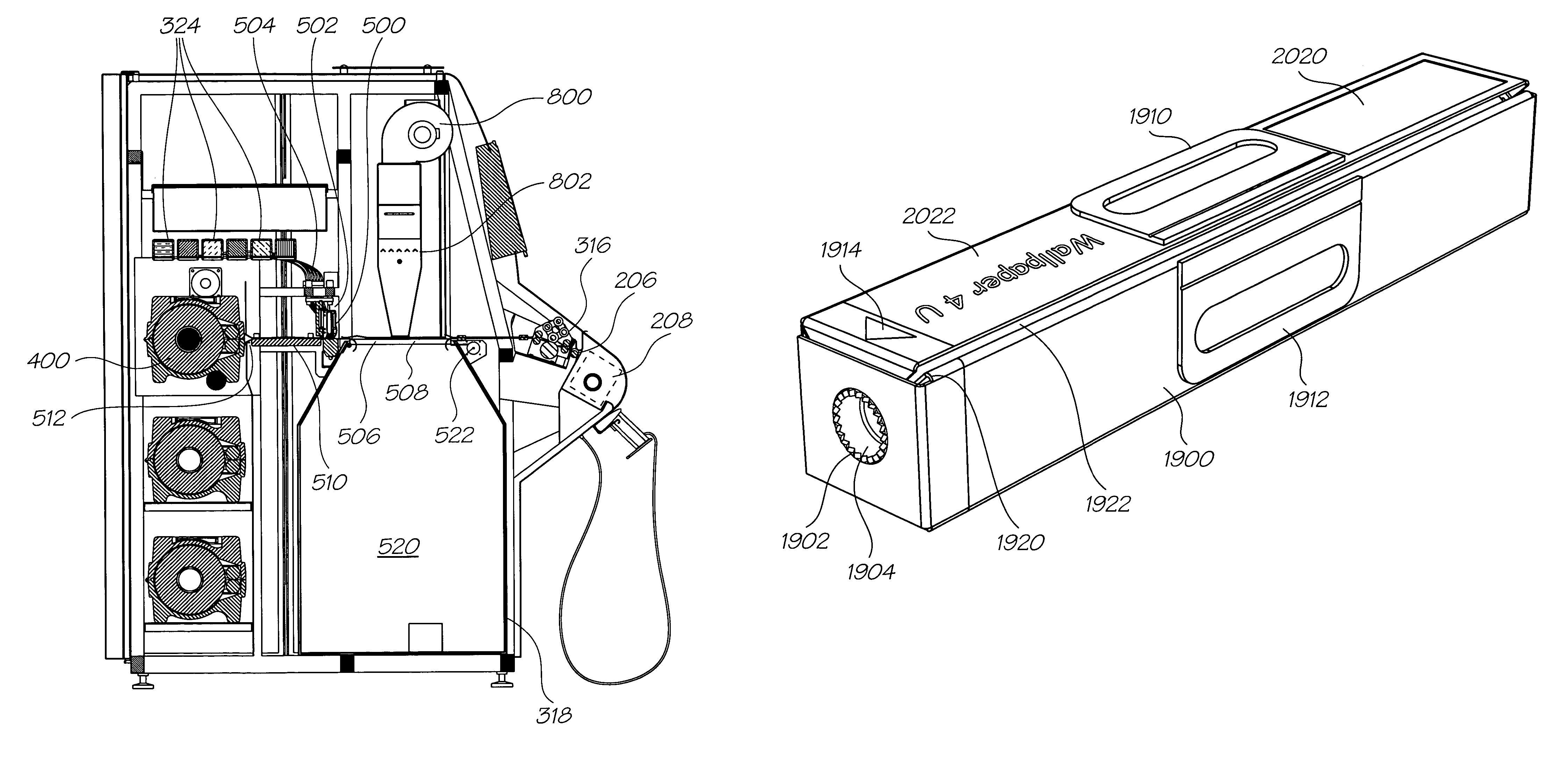

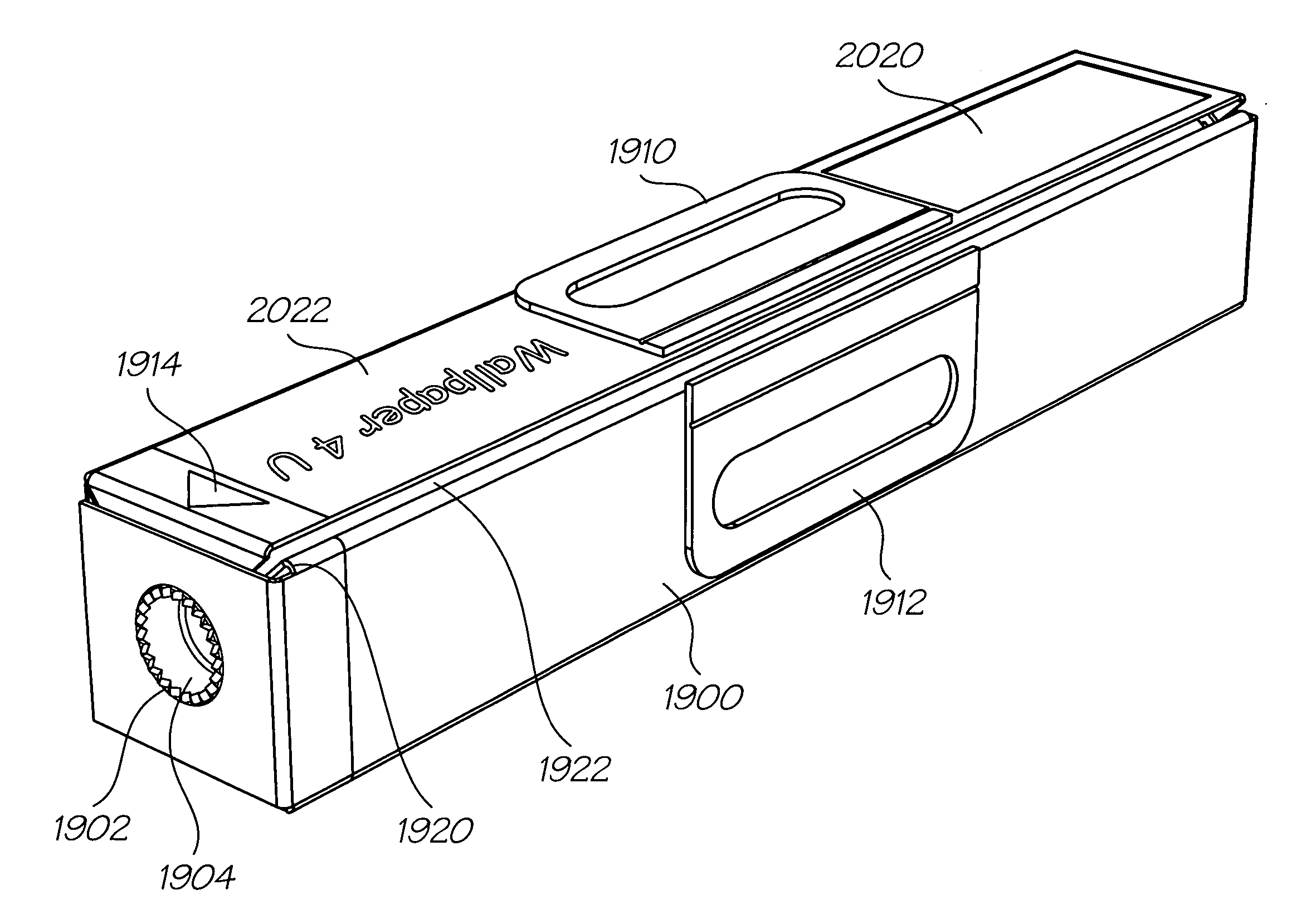

Consumer tote for wallpaper printer

InactiveUS7201272B2Eliminate stock-out, stock-control/ordering and stock obsolesces issuesEliminate inventoryContainers for annular articlesFilament handlingWallpaper printerEngineering

A consumer tote for a roll of wallpaper is disclosed. The tote has a disposable exterior with a main access flap and a pair of core access openings, one at each end. The tote has an interior in which may be located a disposable core. The core aligns with the access openings. In some embodiments there is a gap between the access flap and an adjacent edge of the exterior, when the flap is closed. In preferred embodiments, the core is supported at each end by a molding having a hub which engages the core.

Owner:MEMJET TECH LTD +1

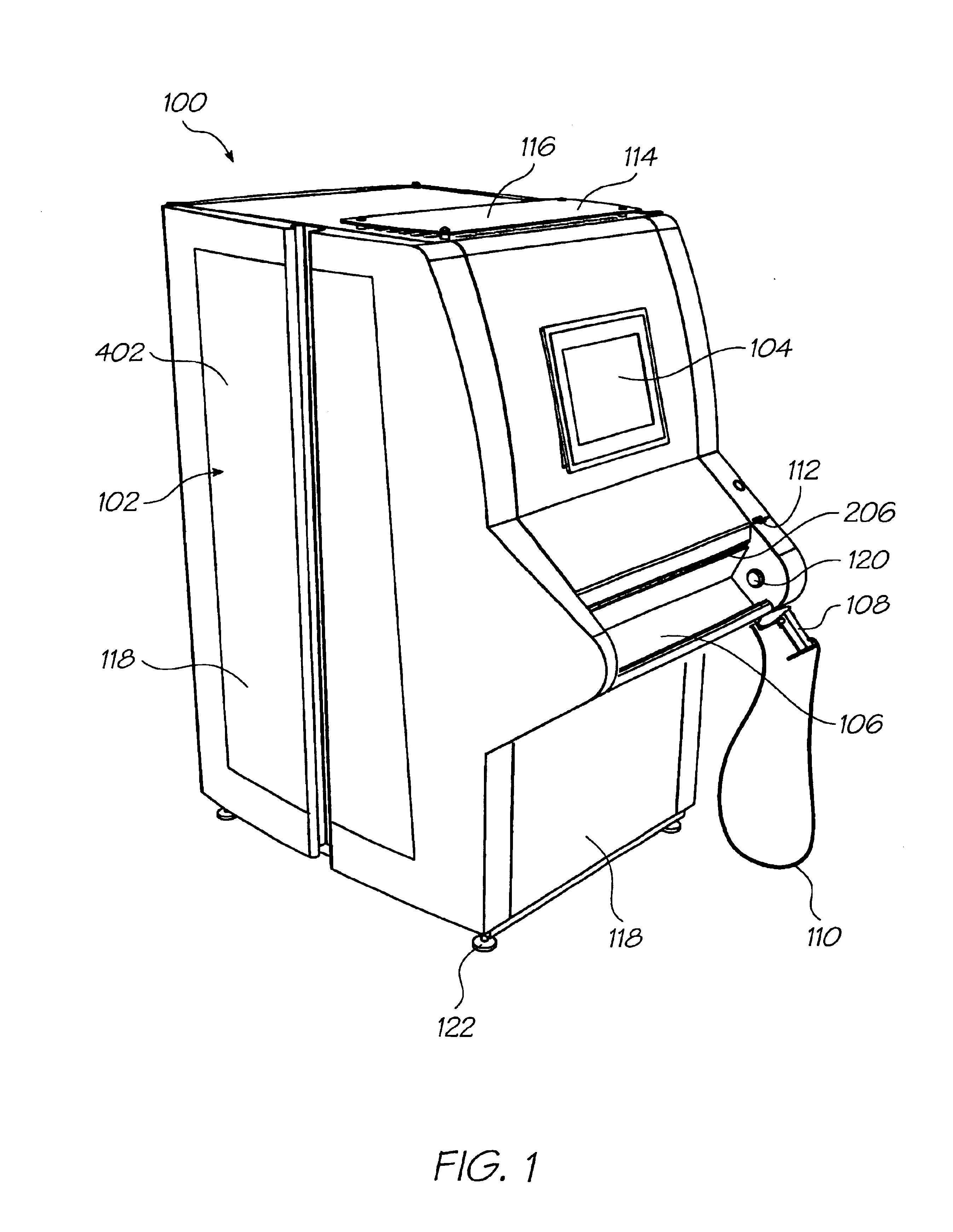

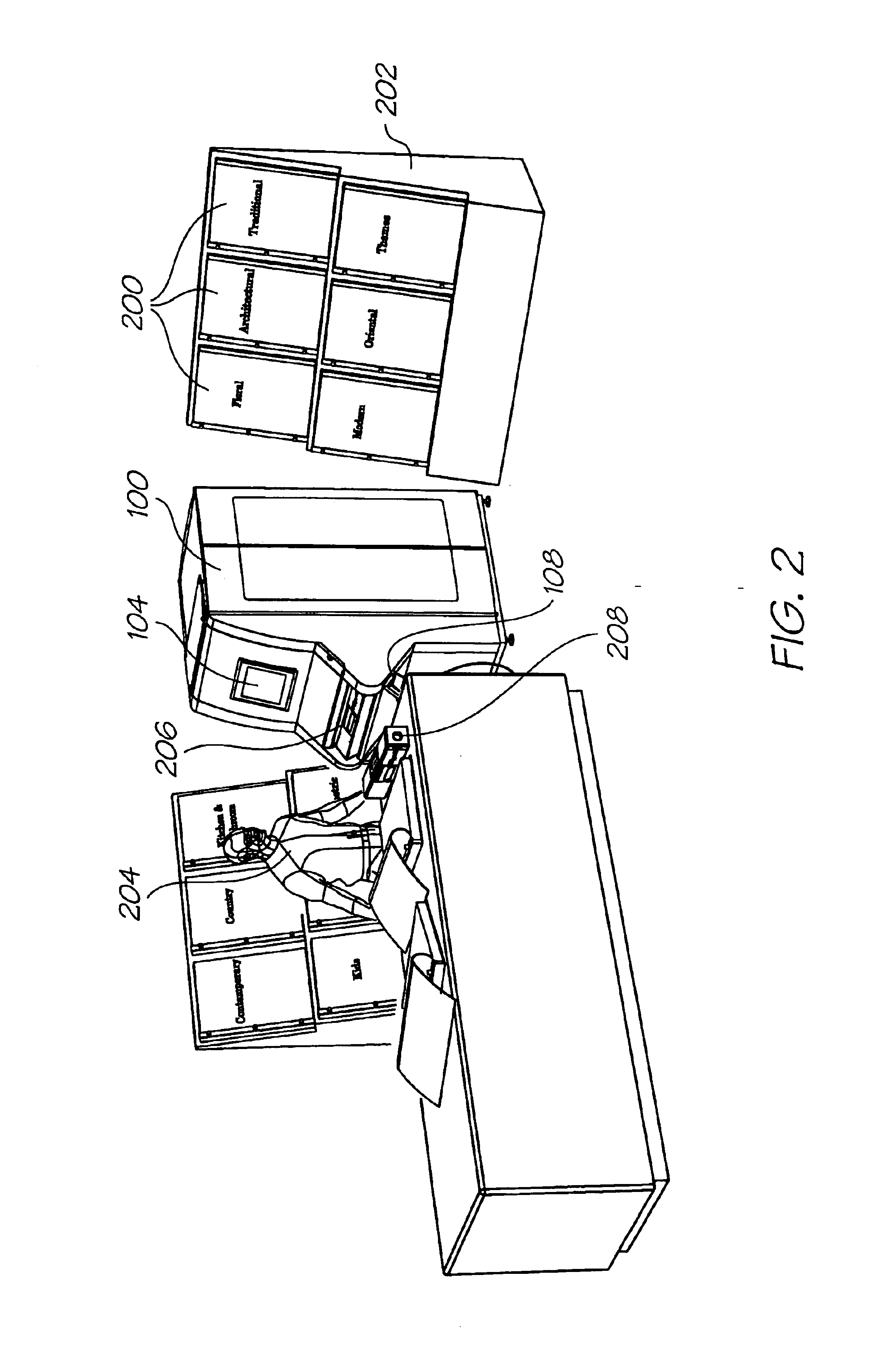

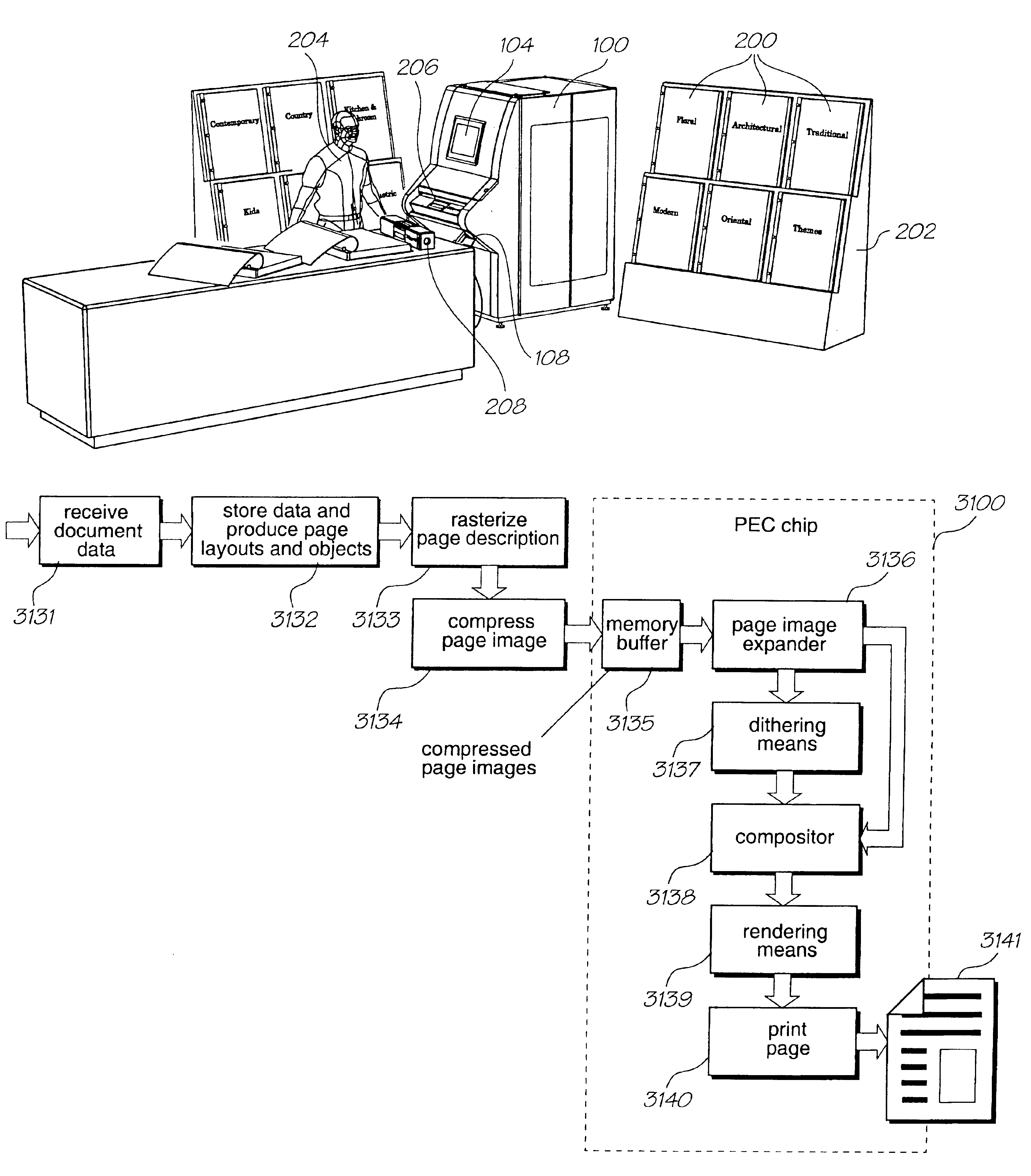

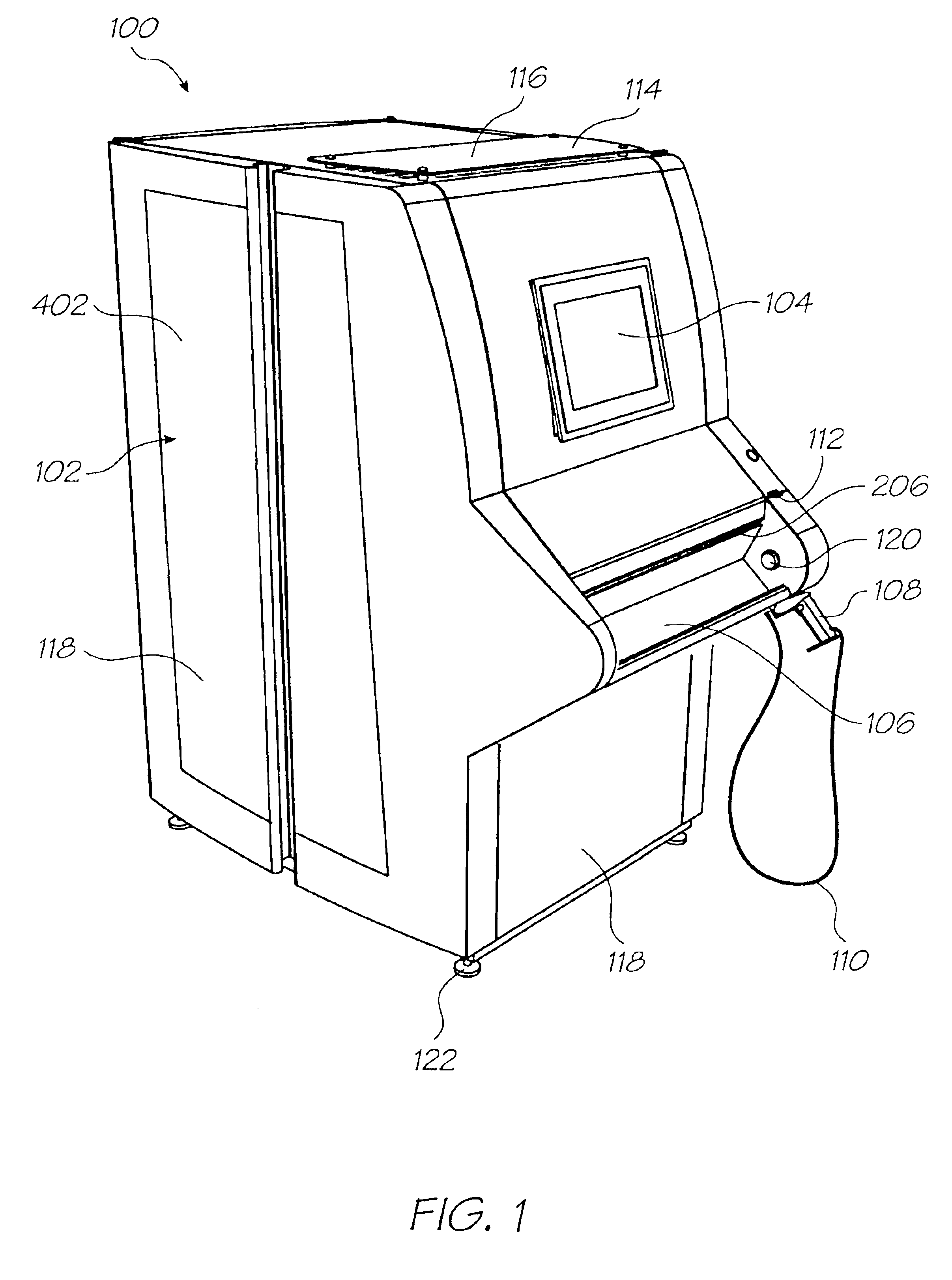

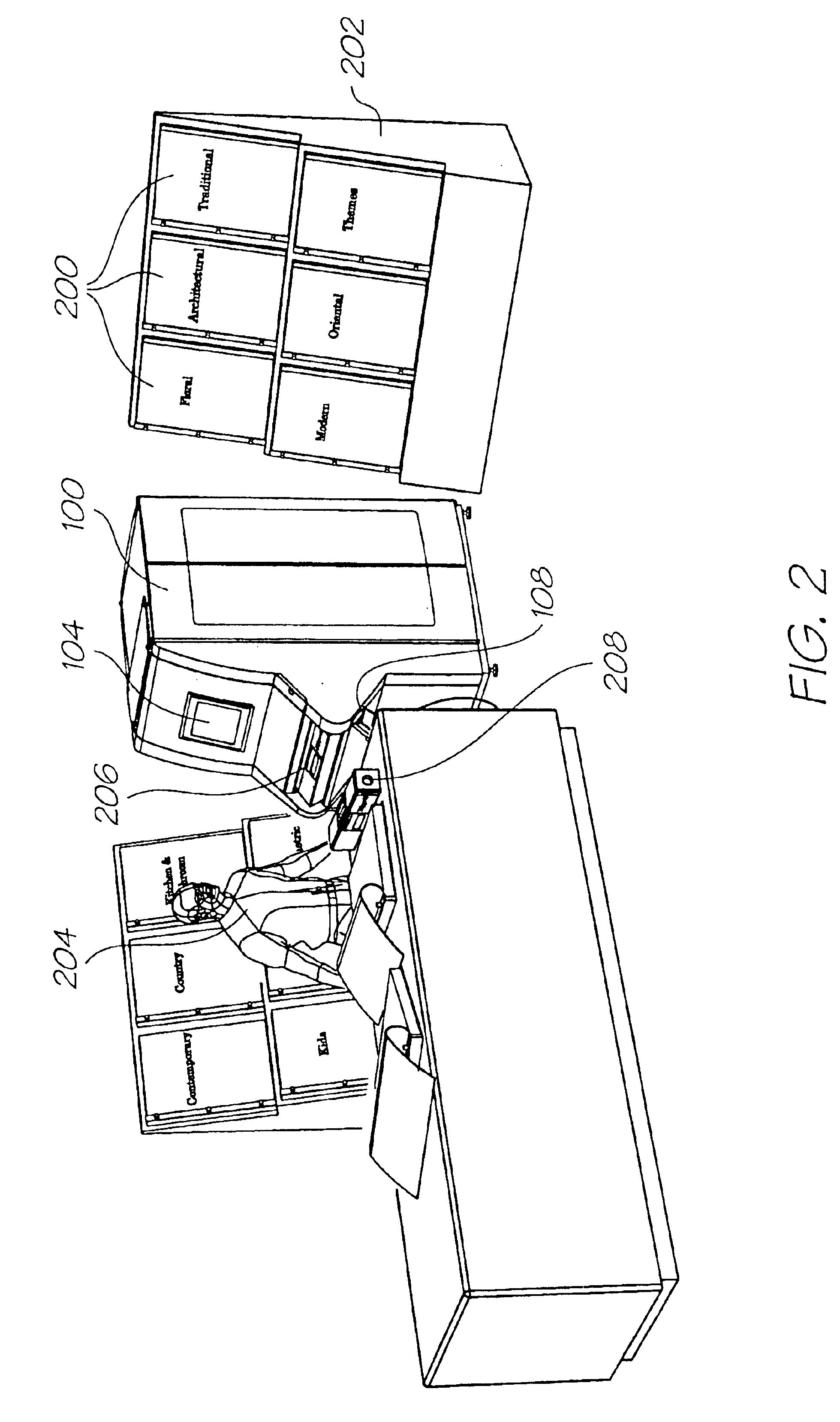

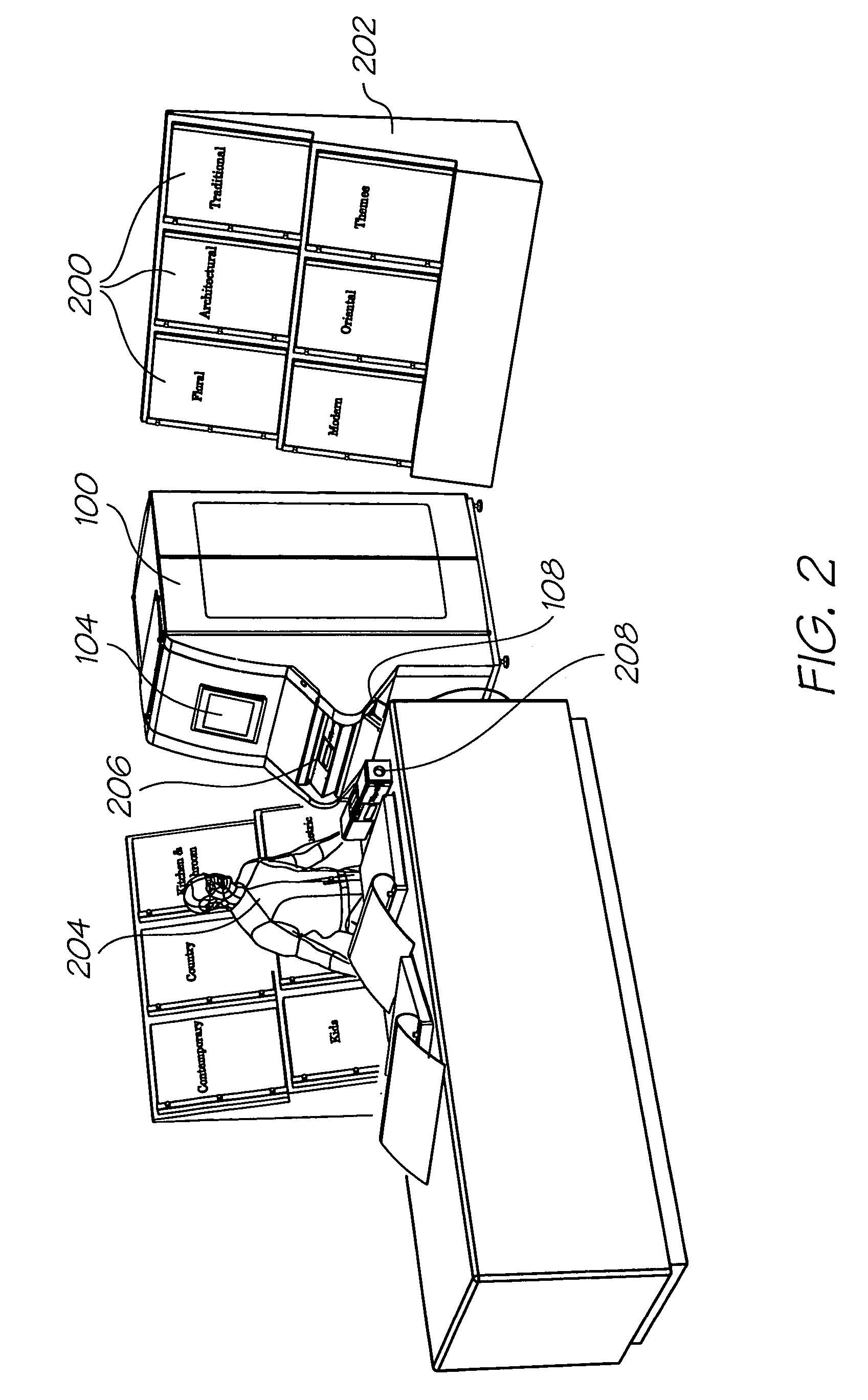

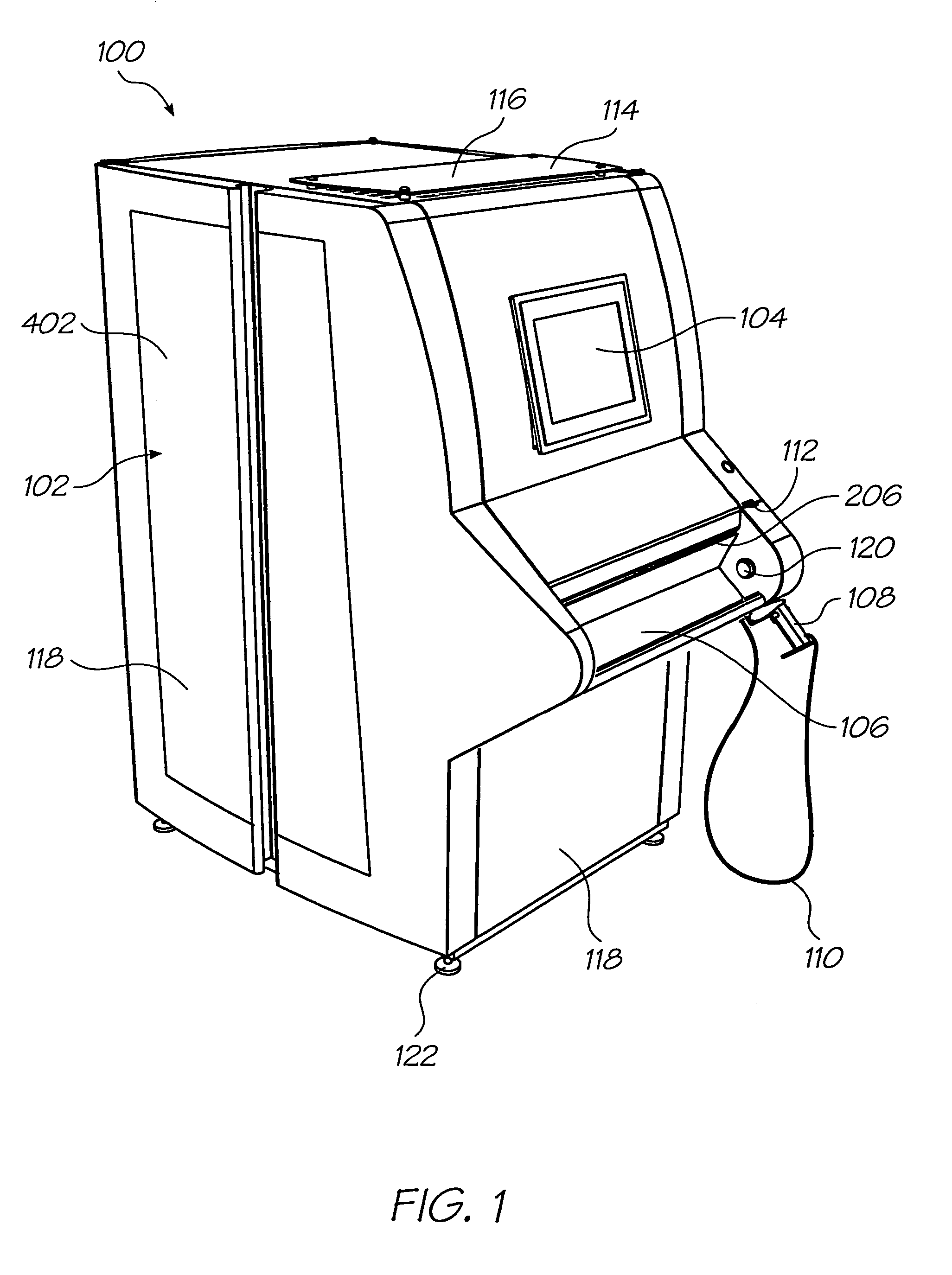

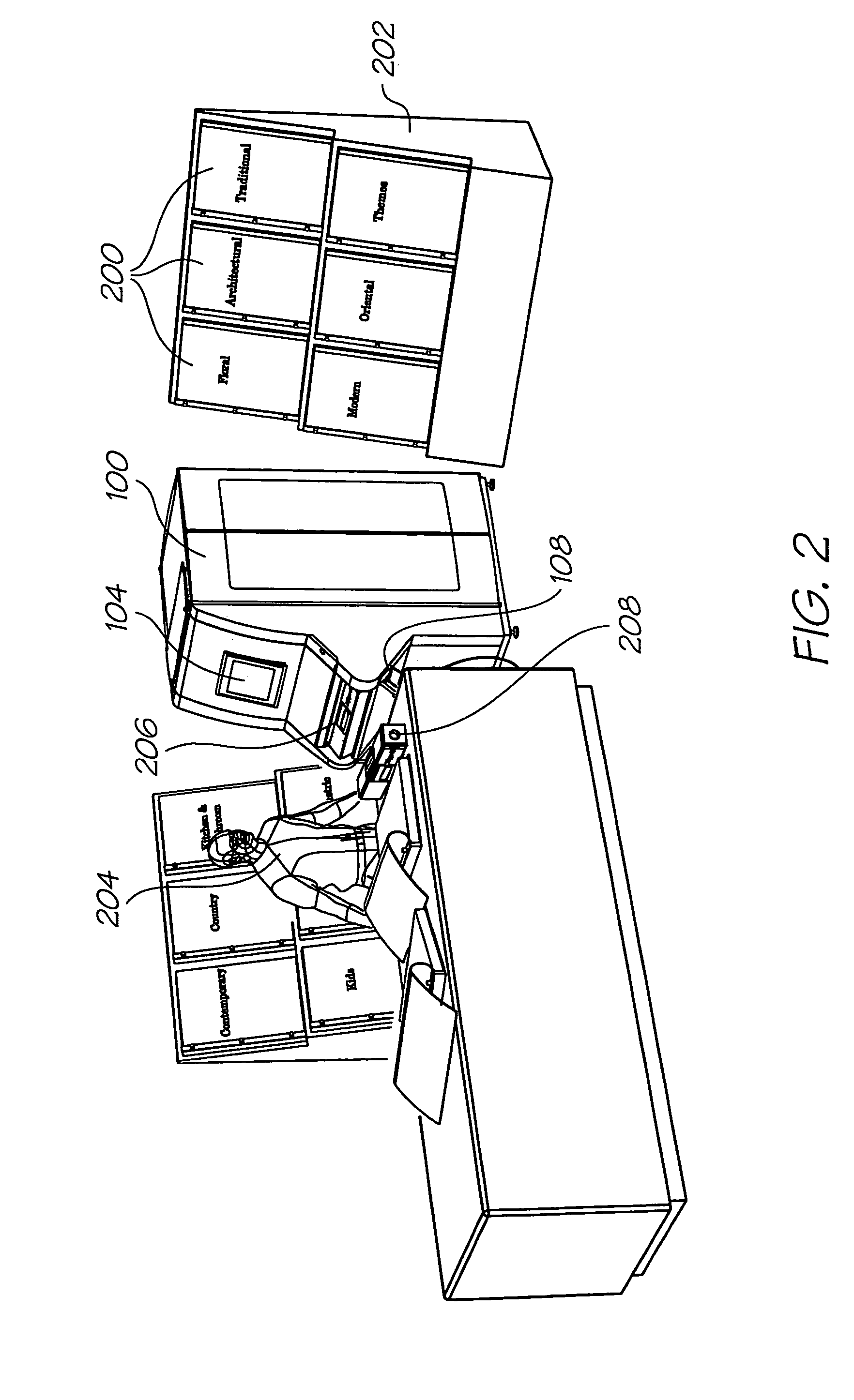

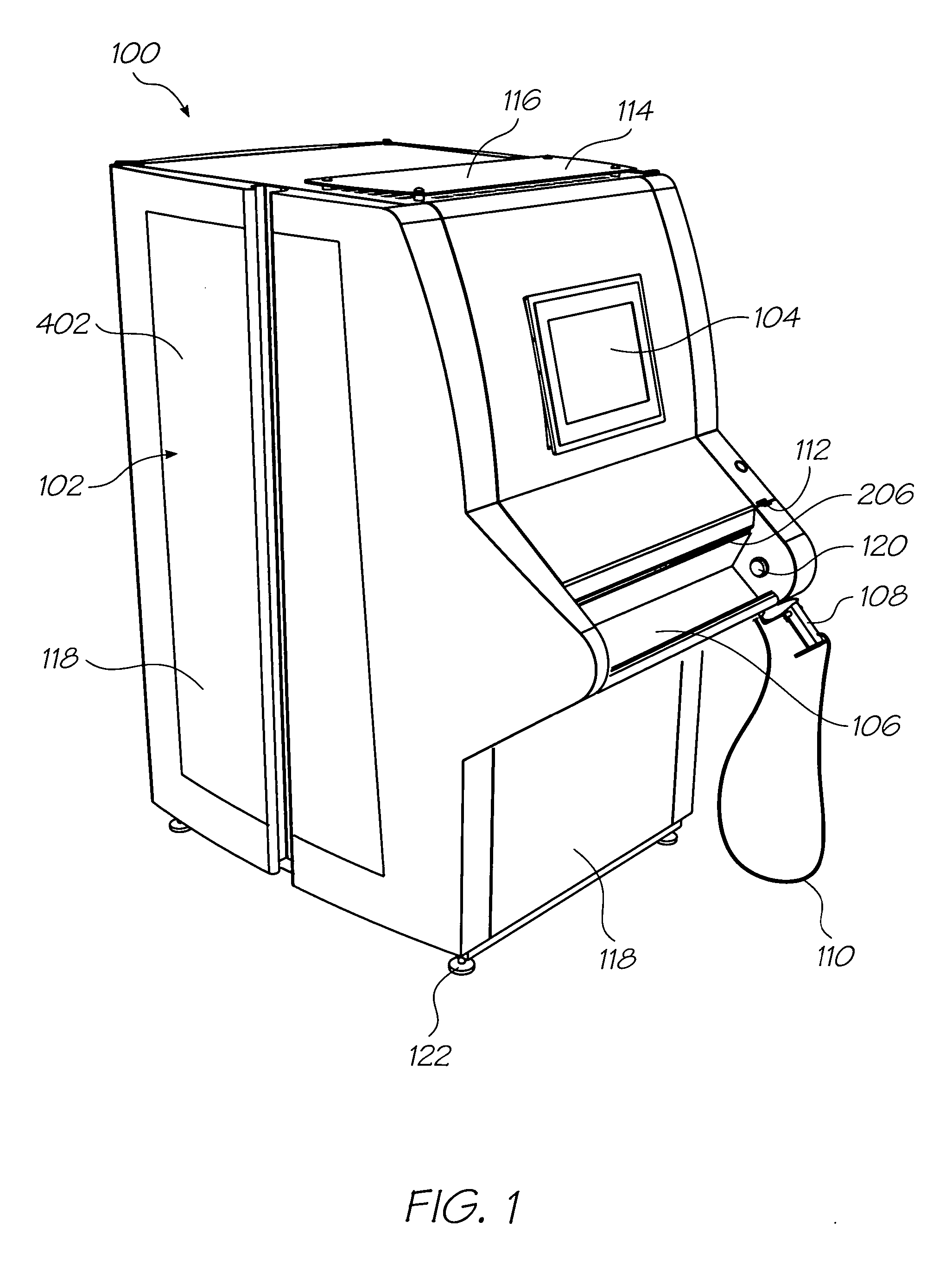

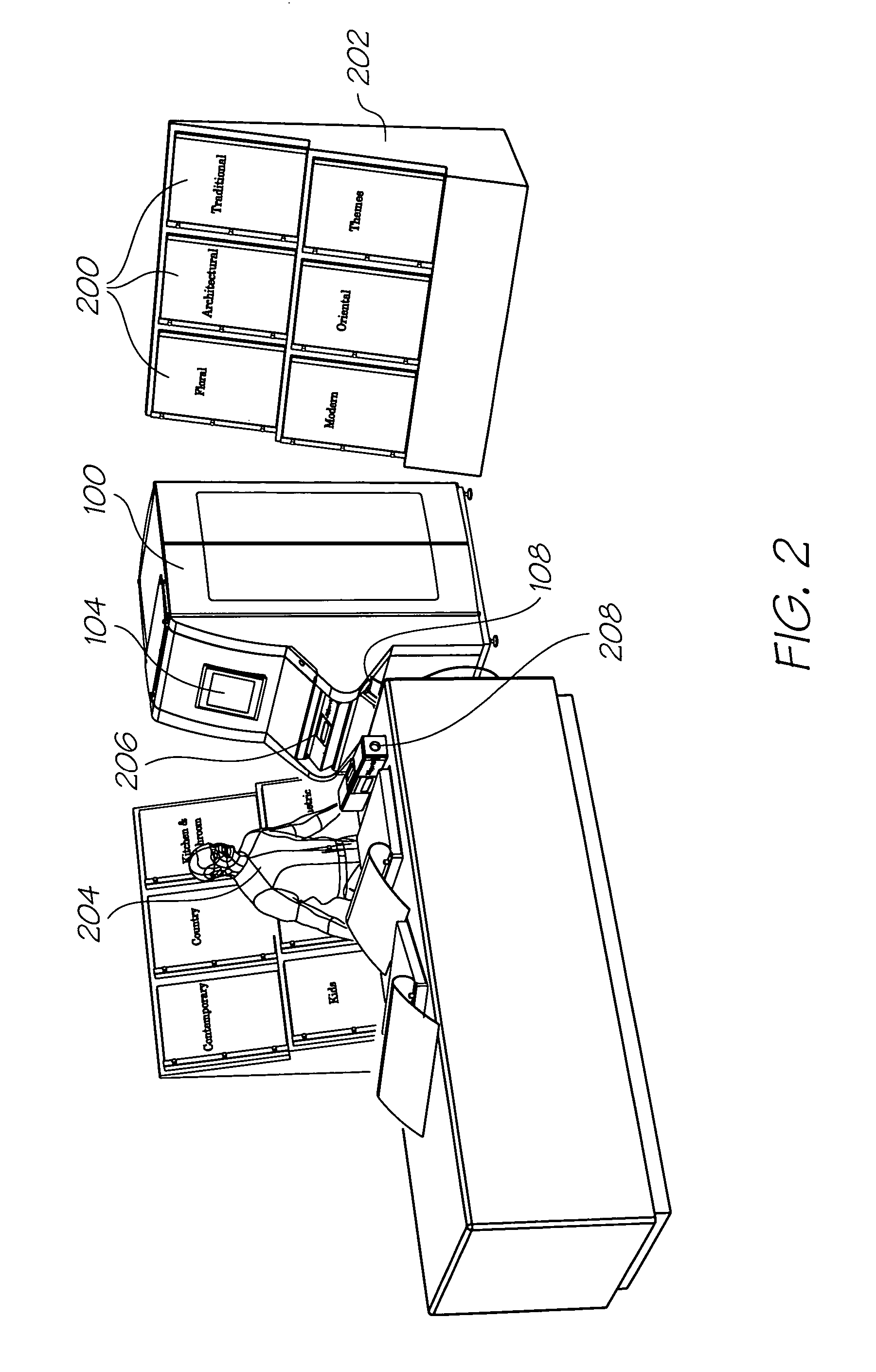

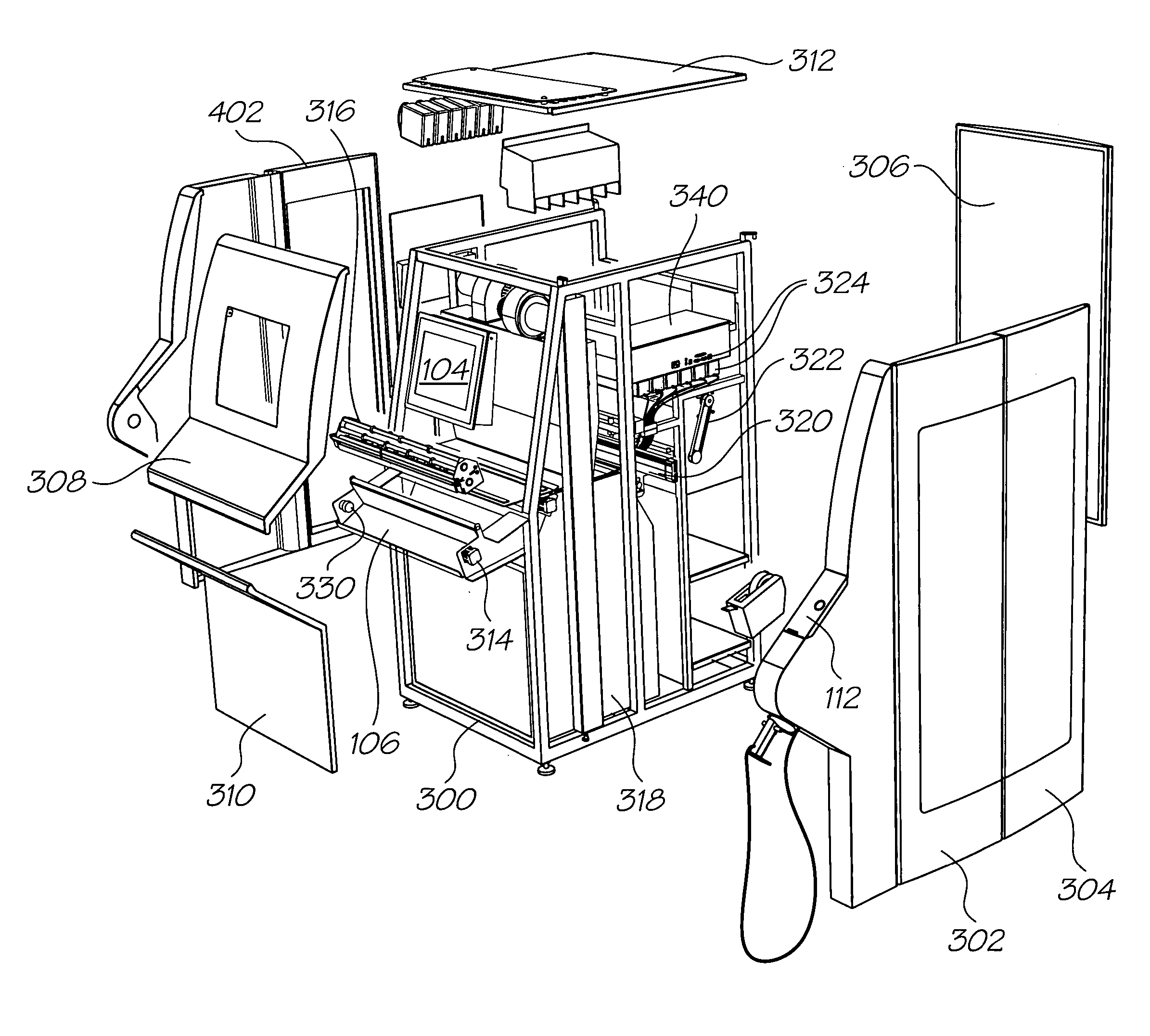

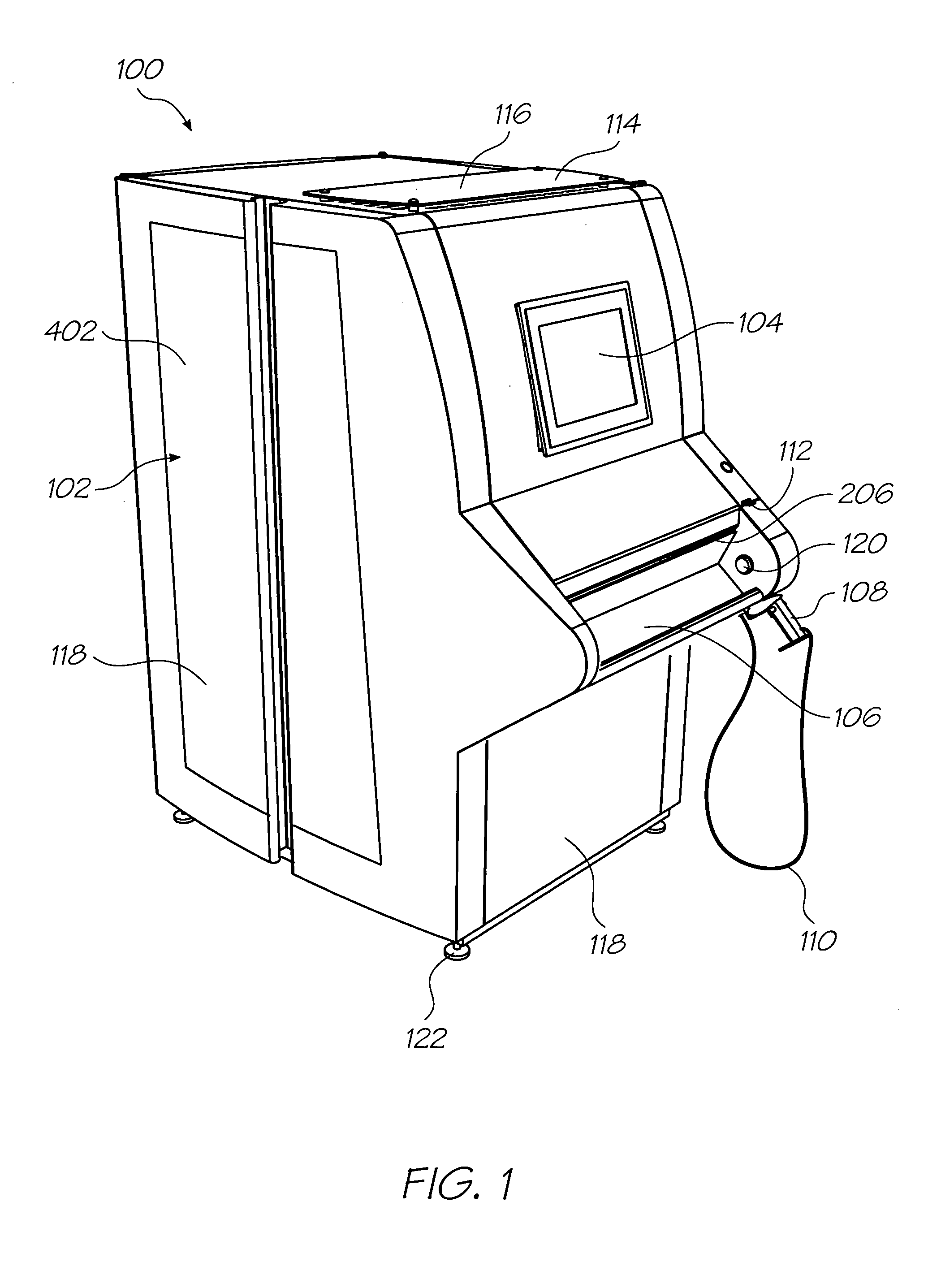

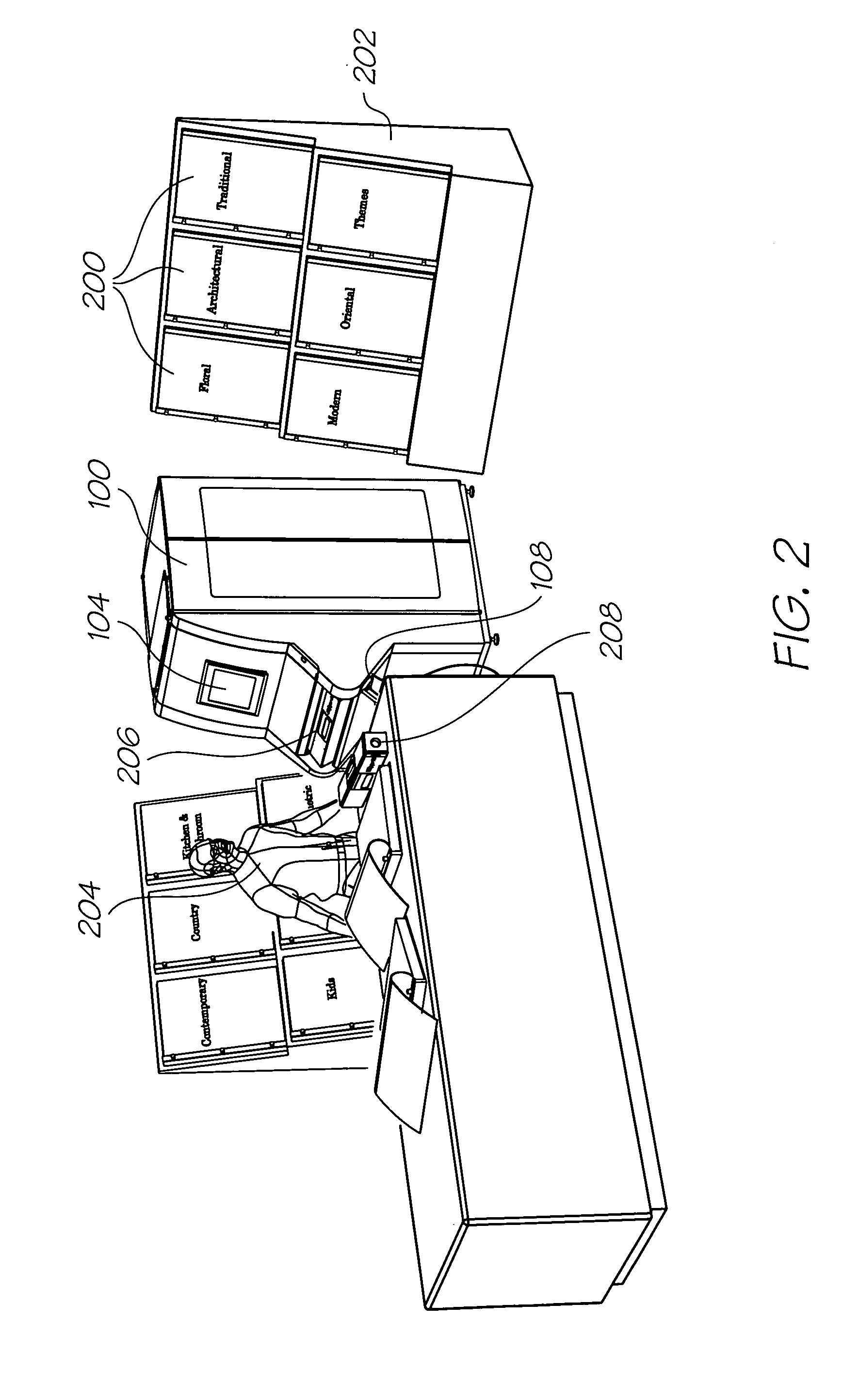

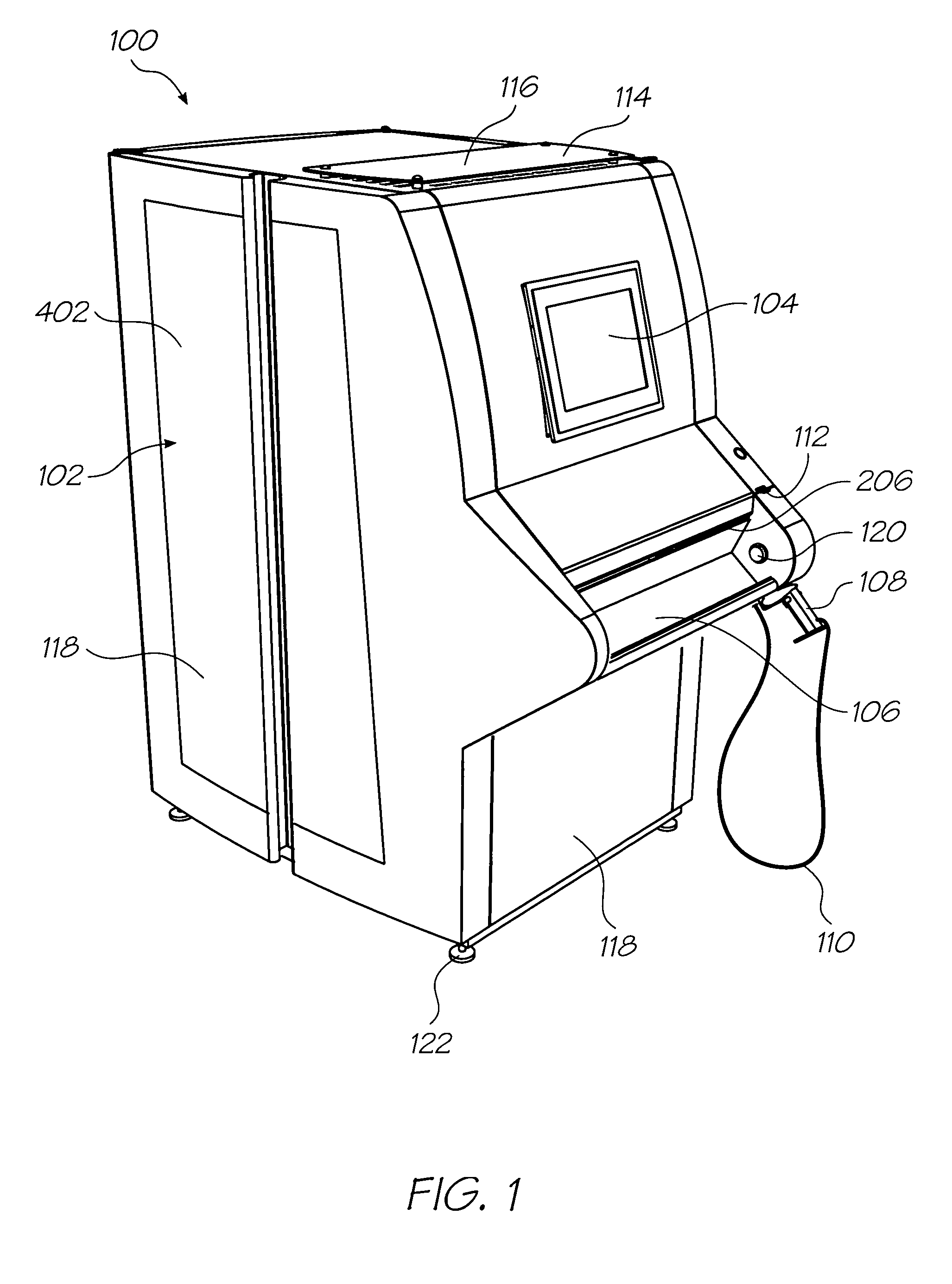

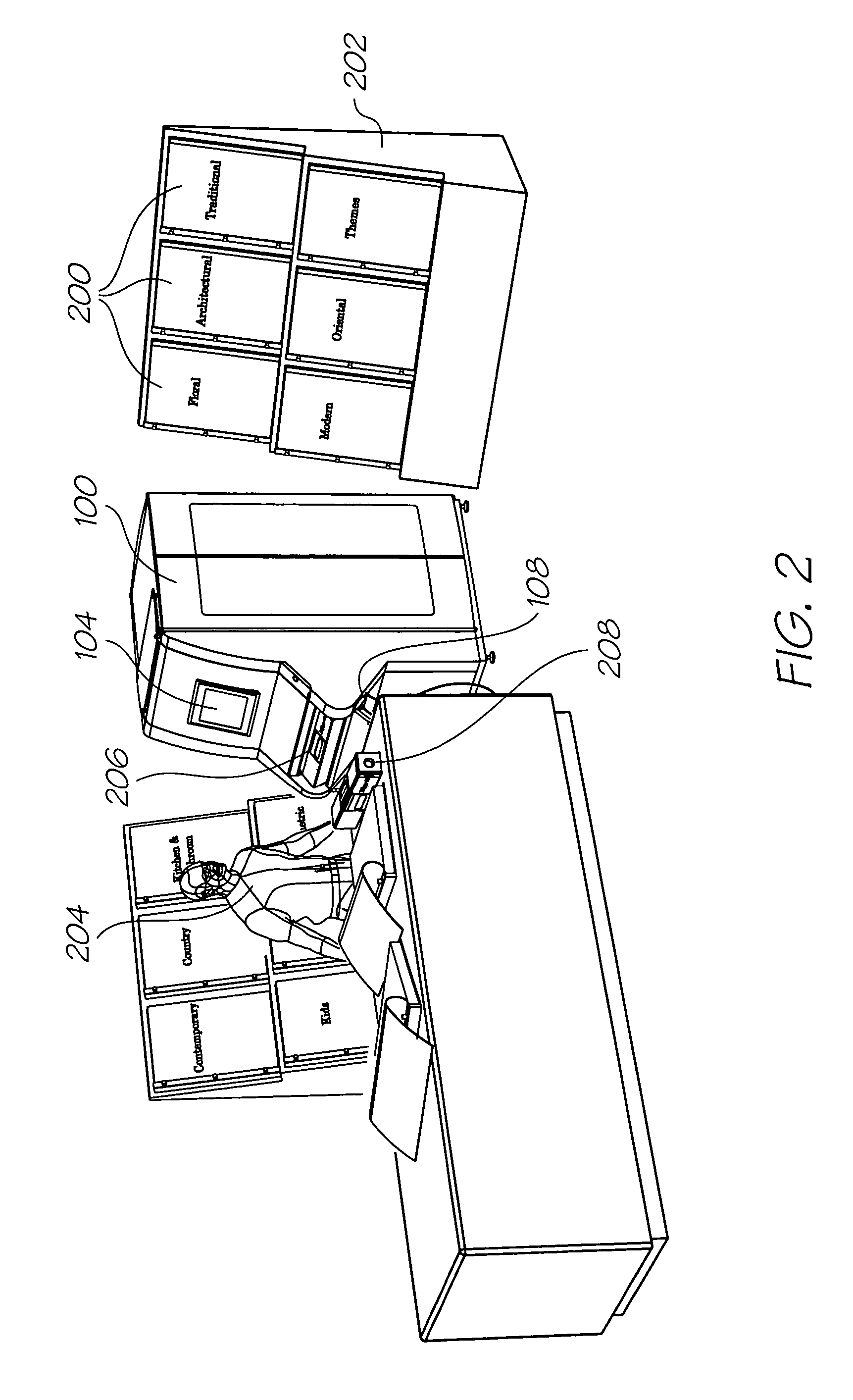

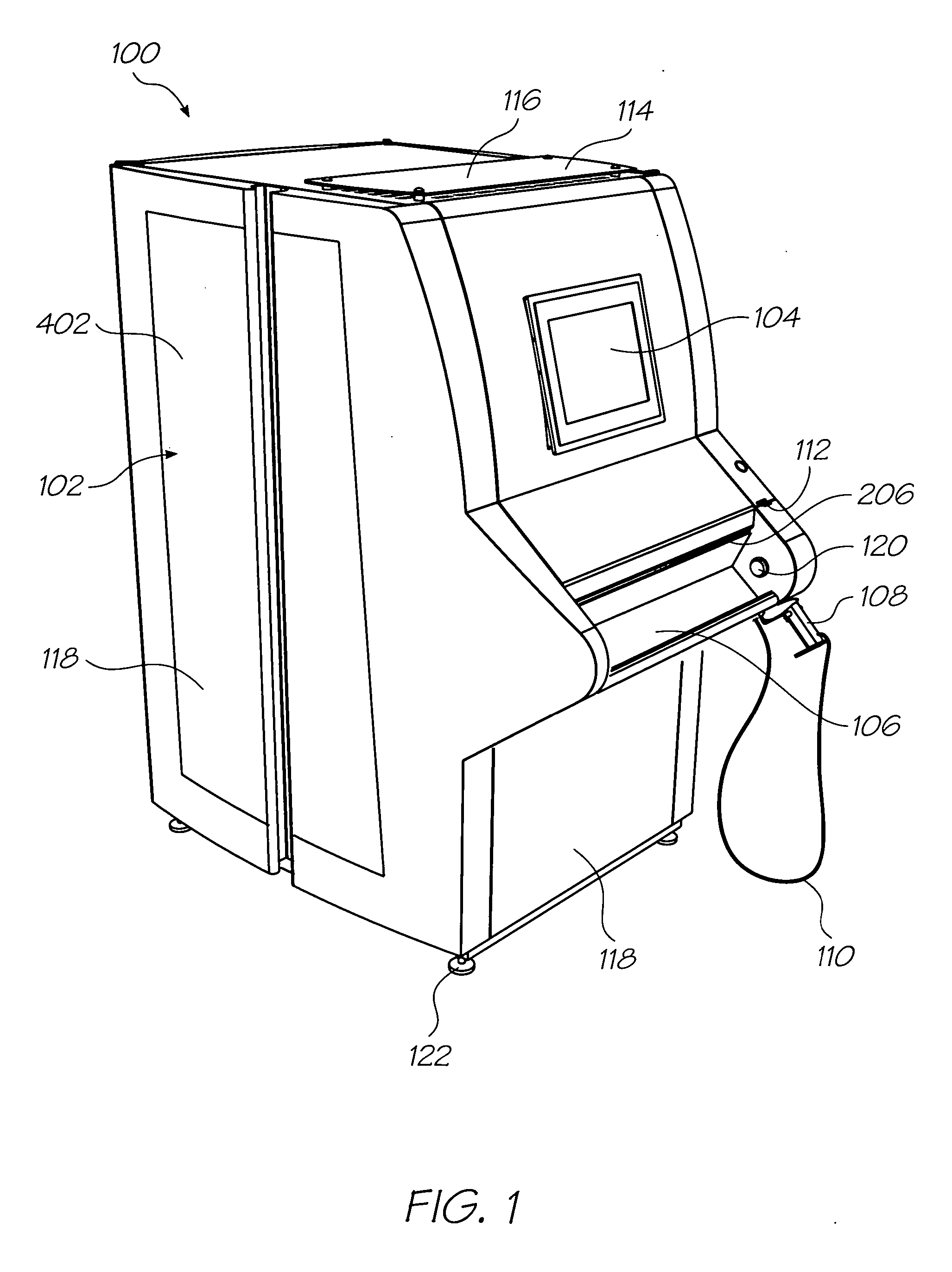

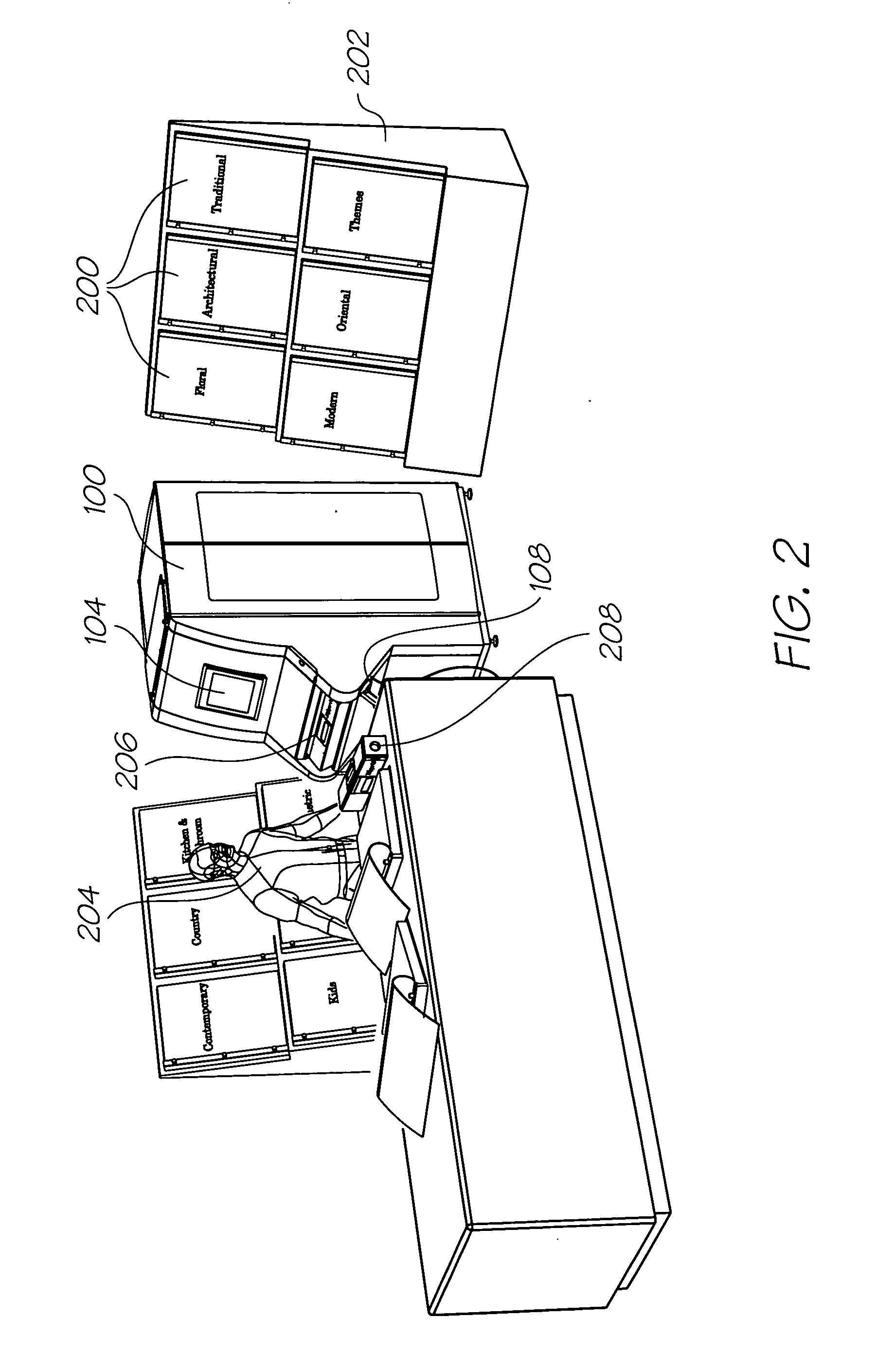

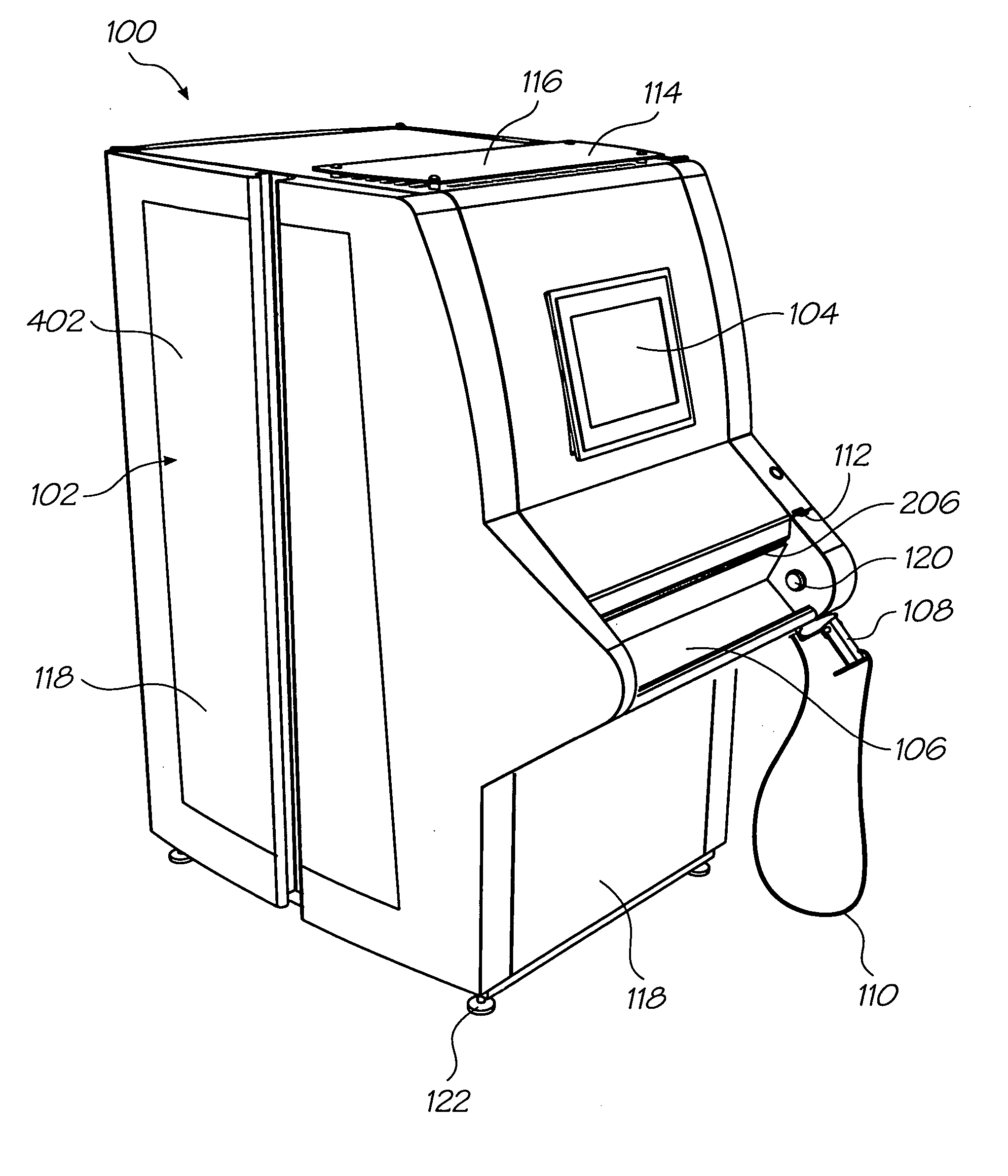

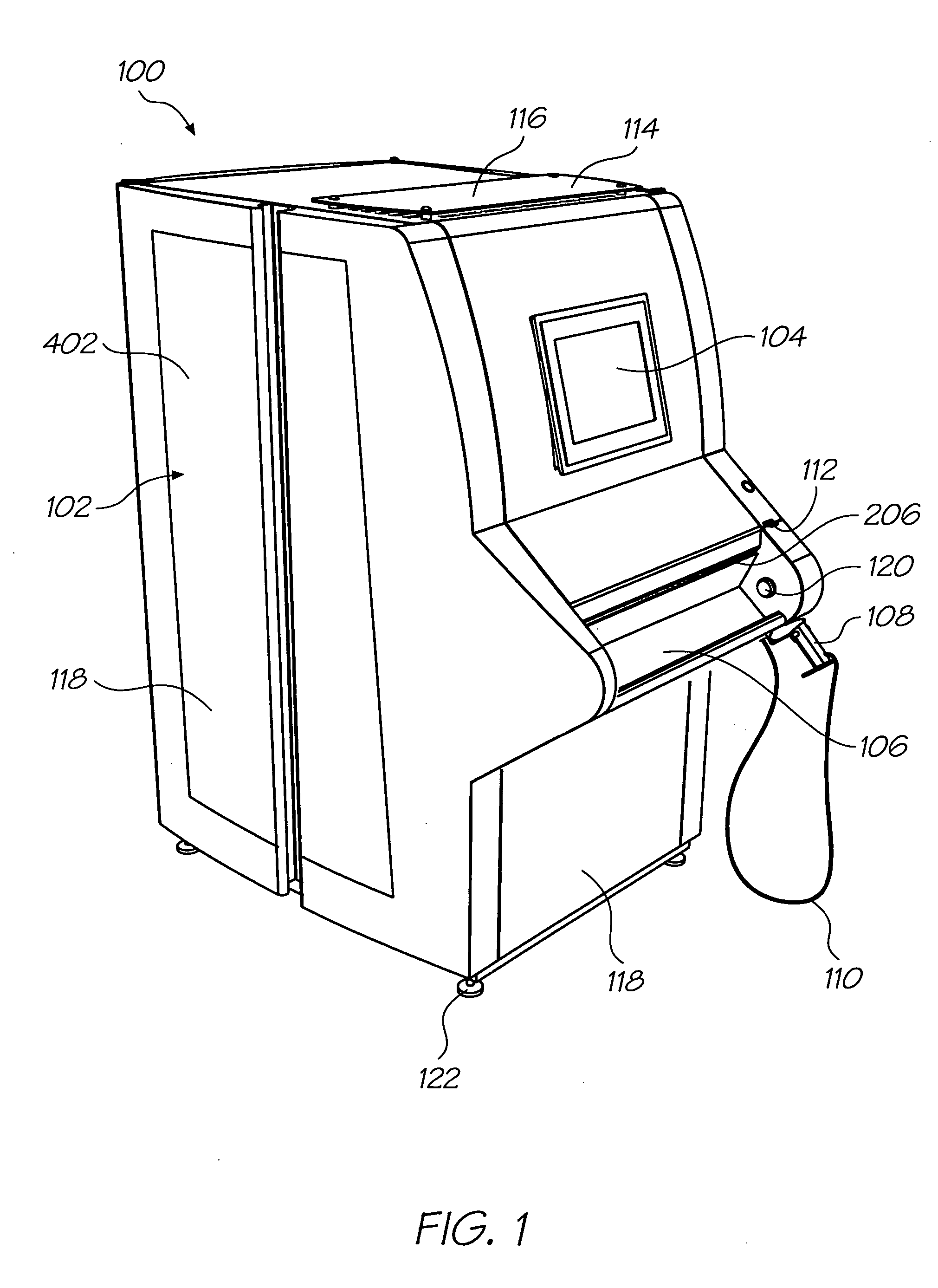

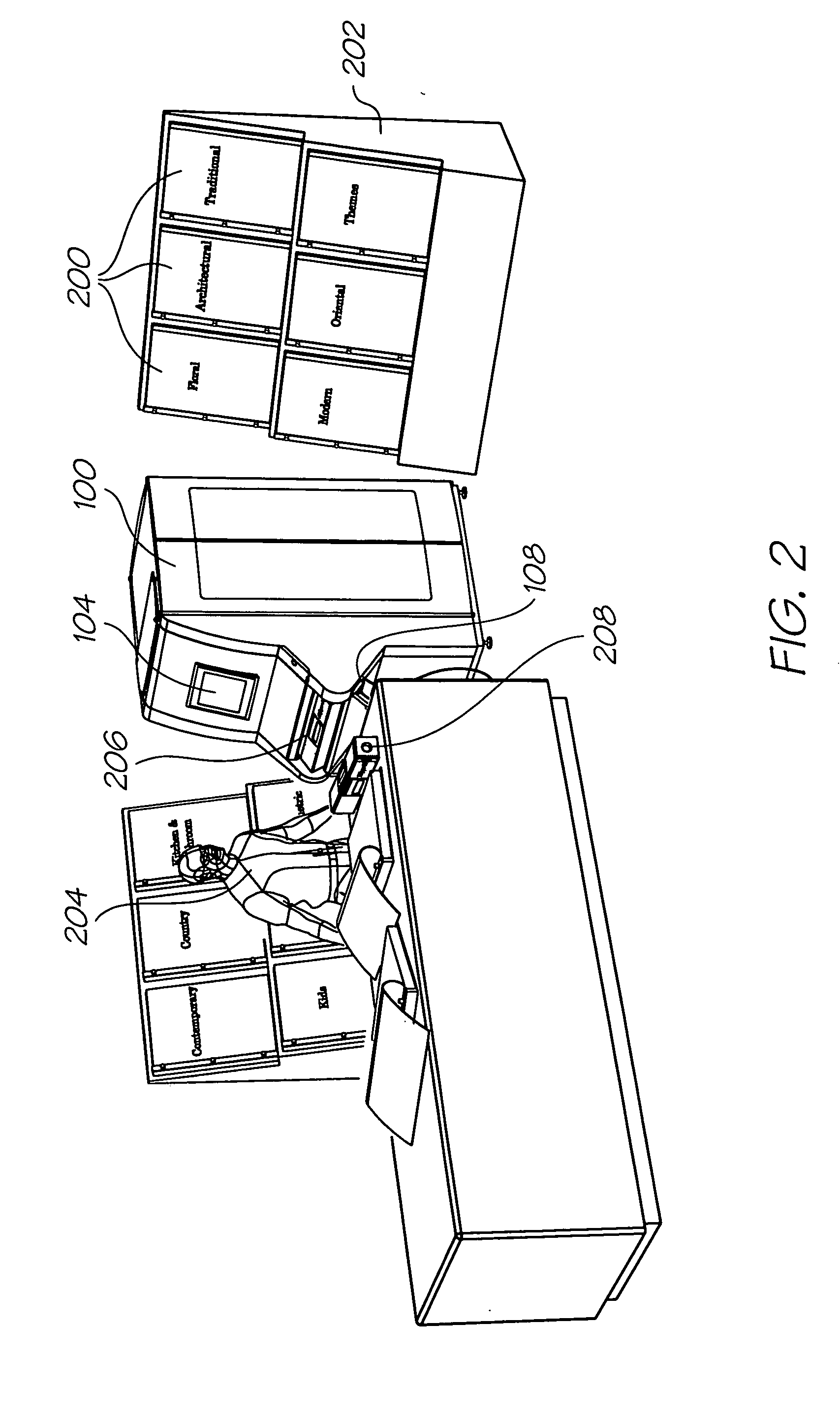

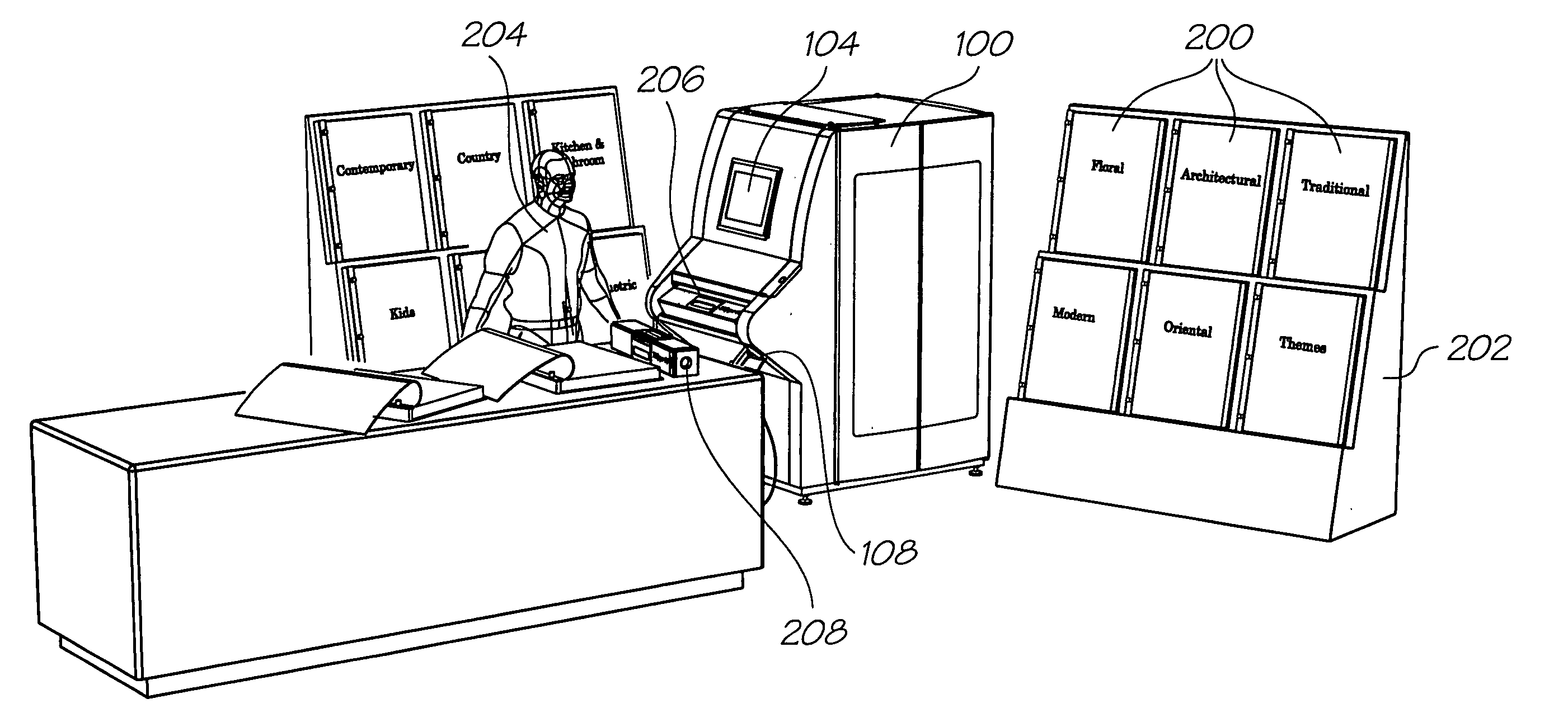

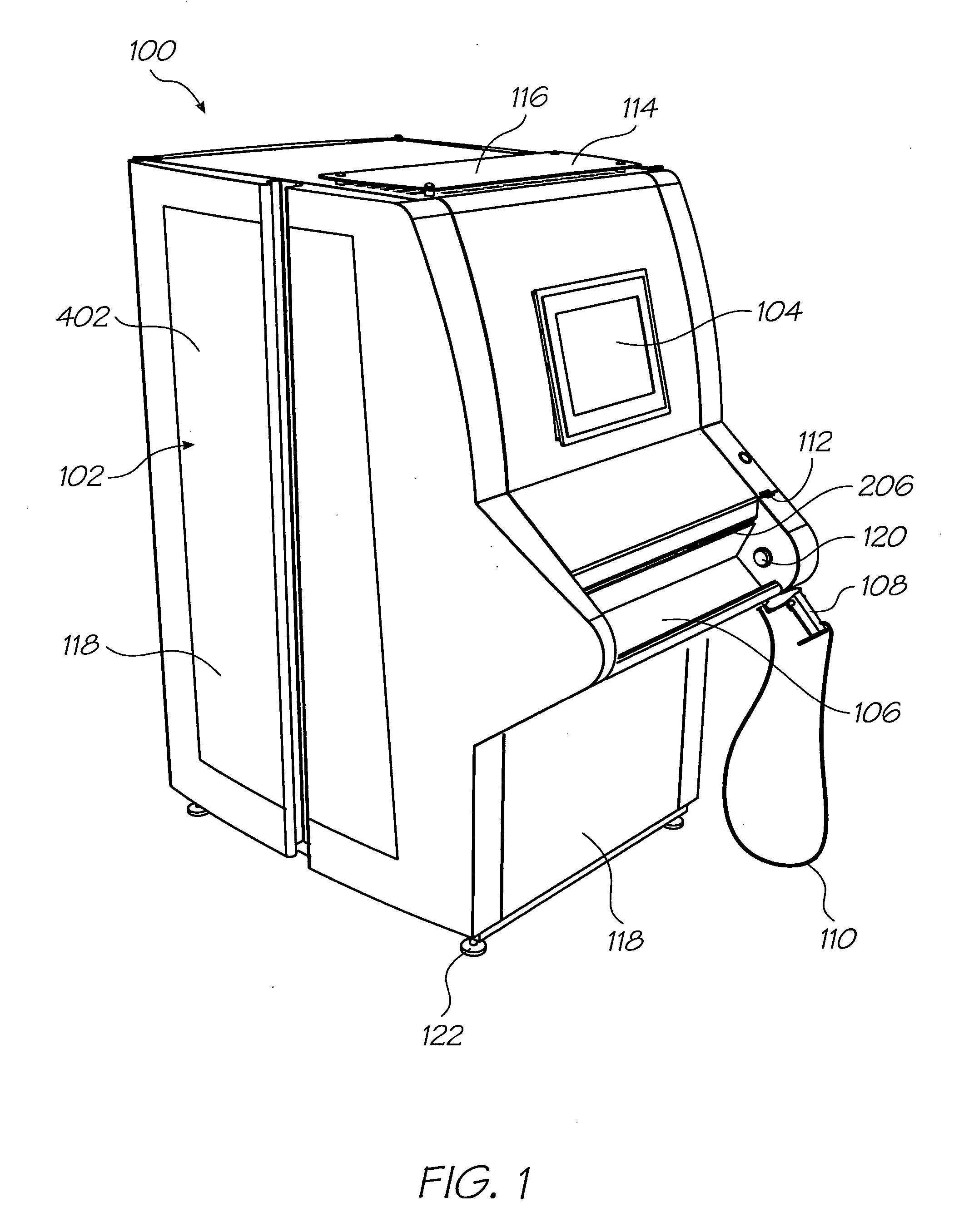

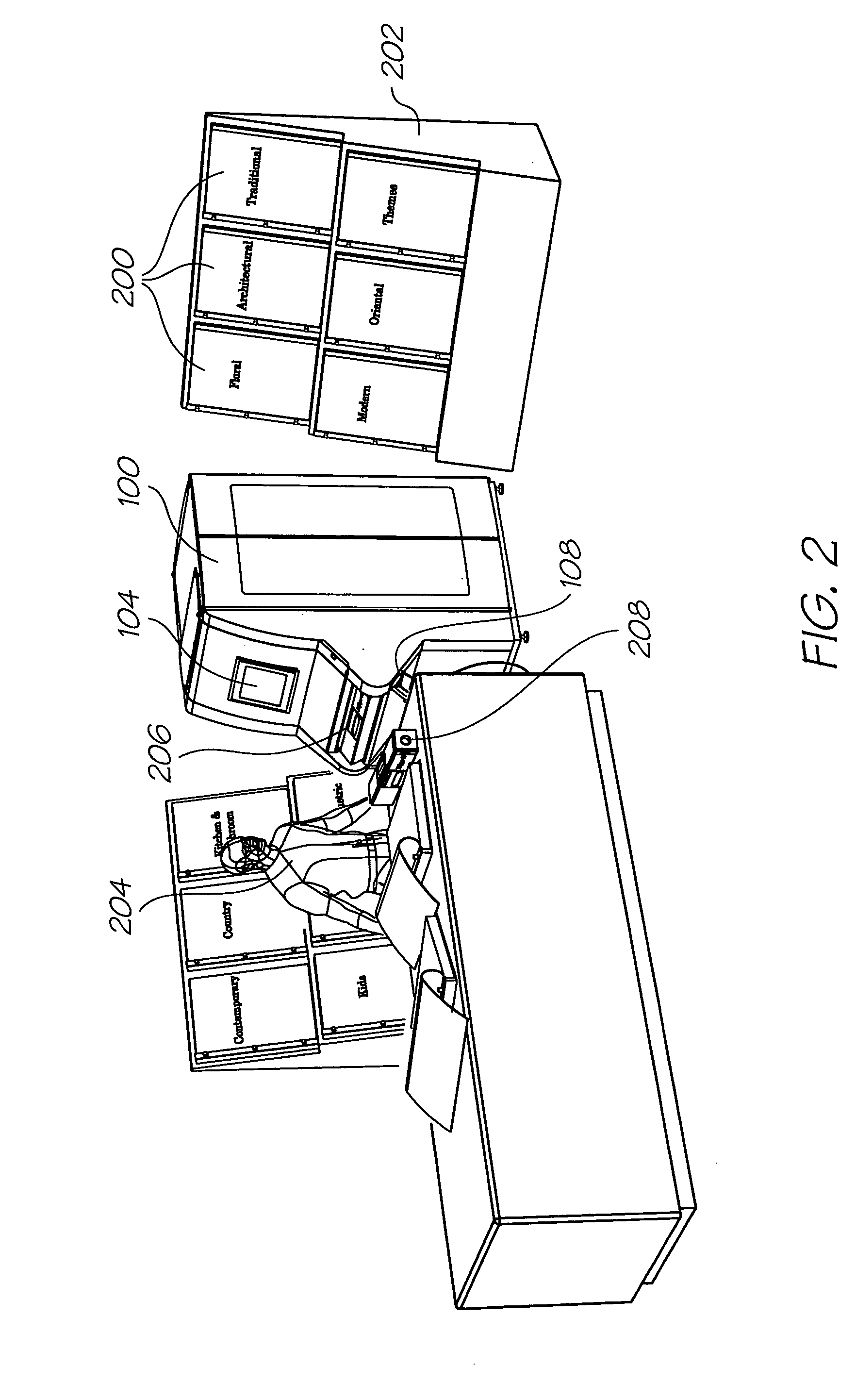

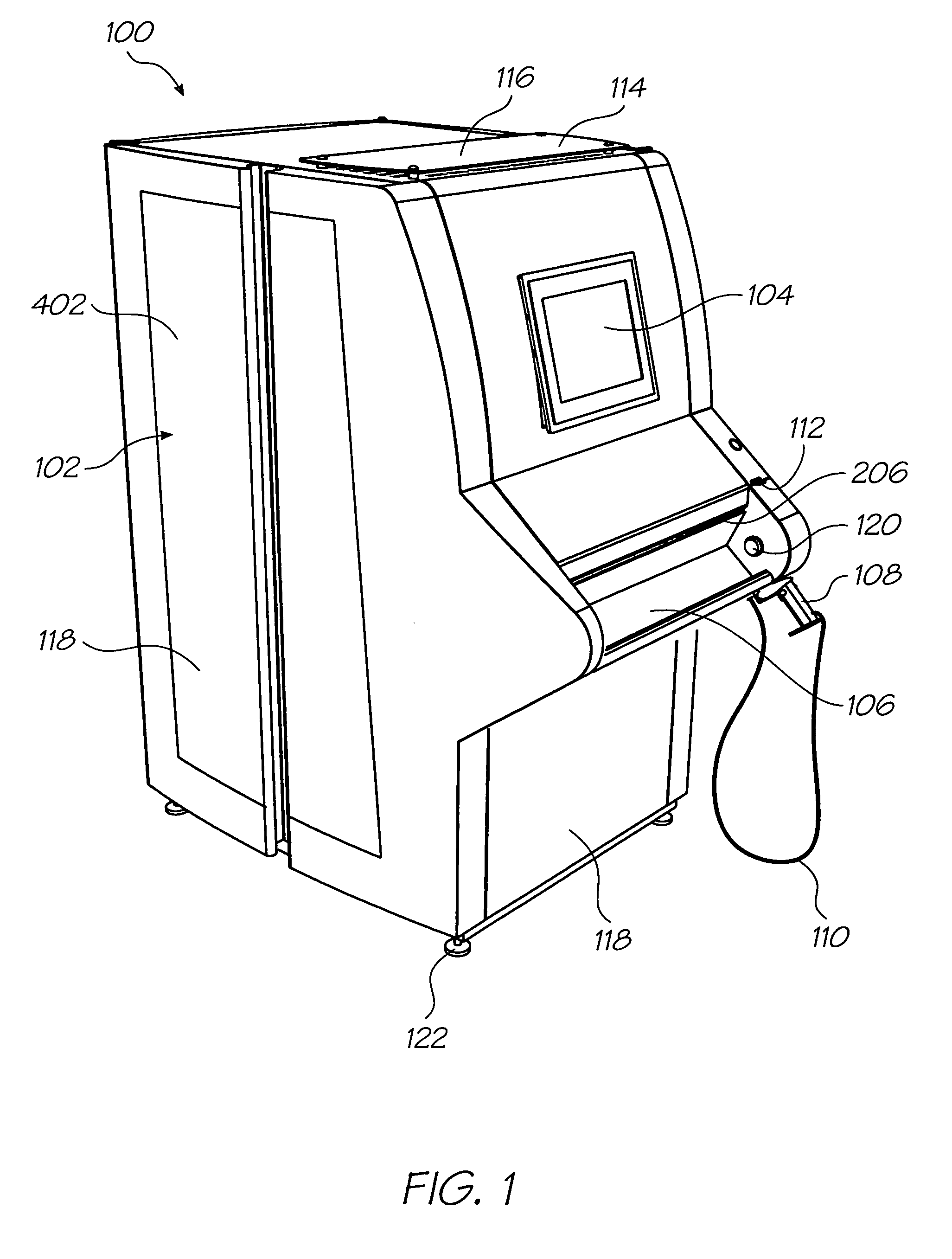

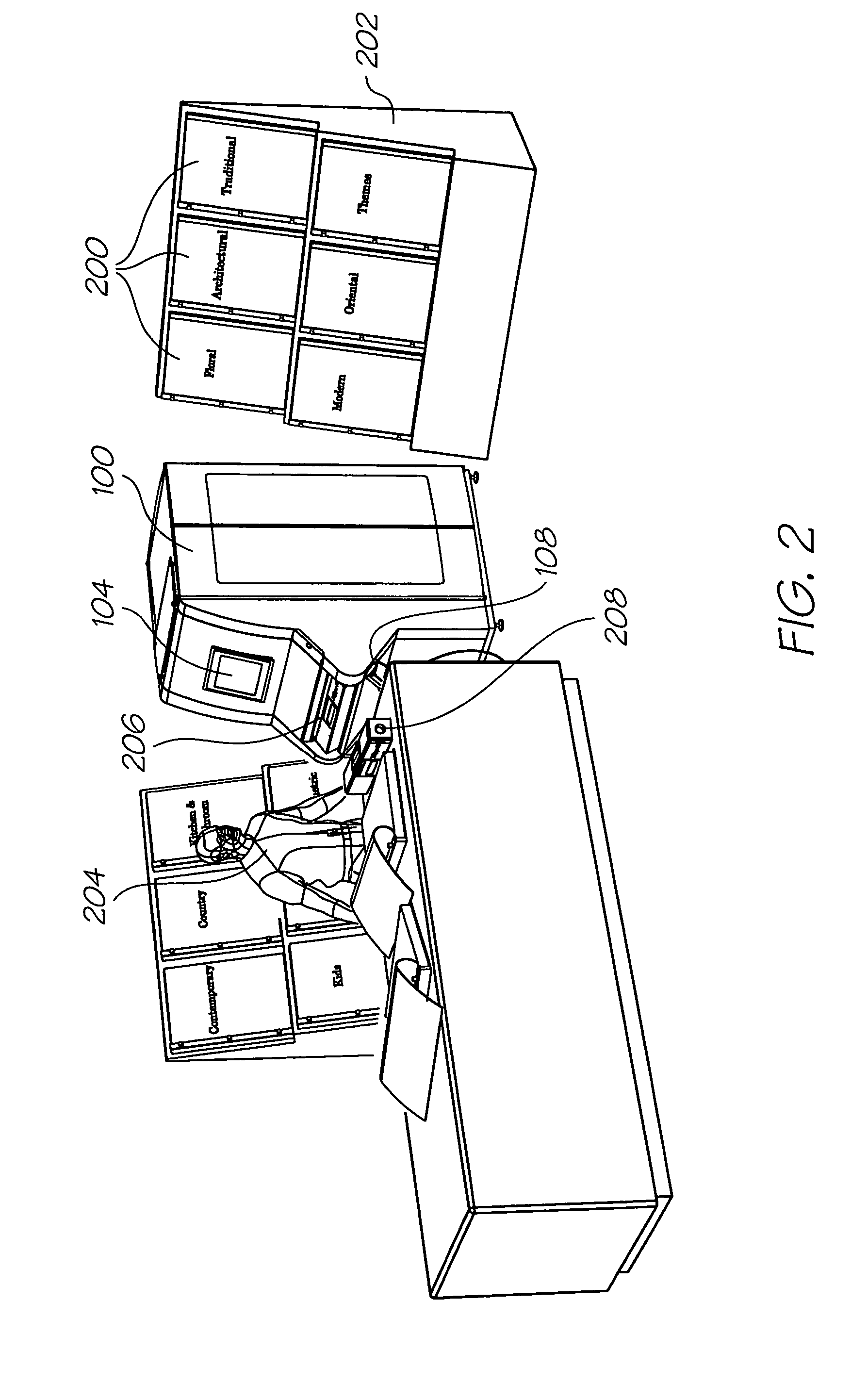

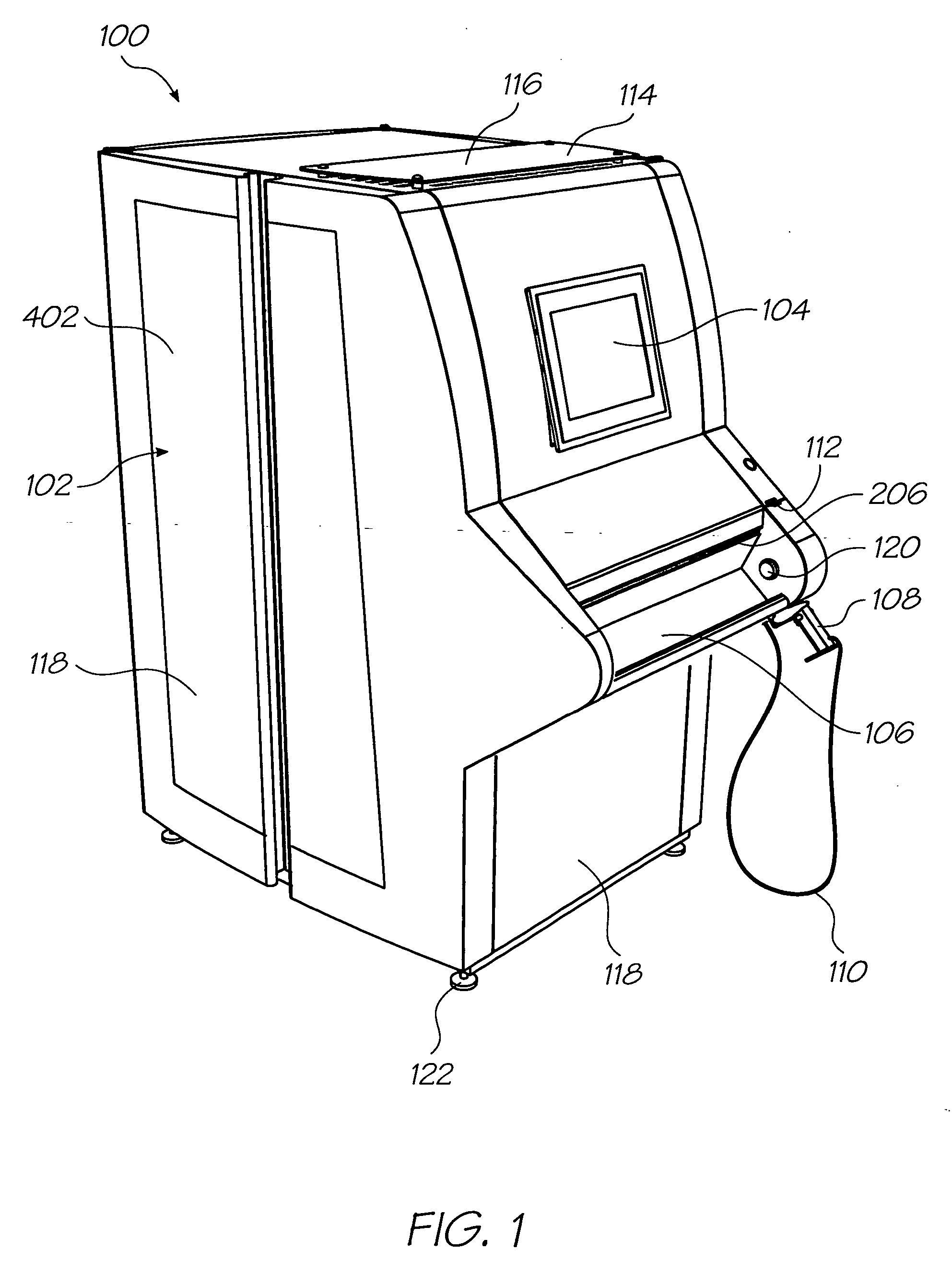

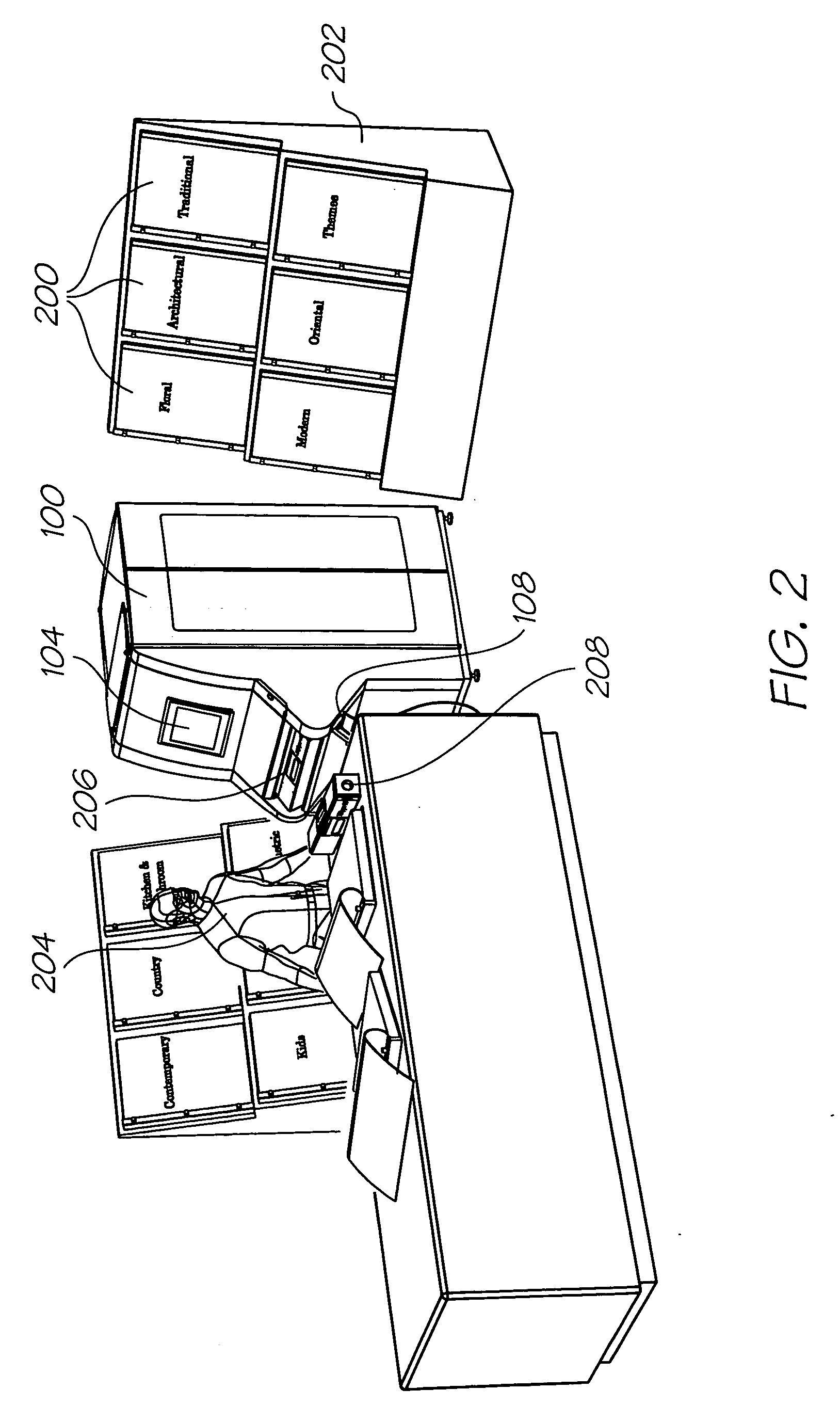

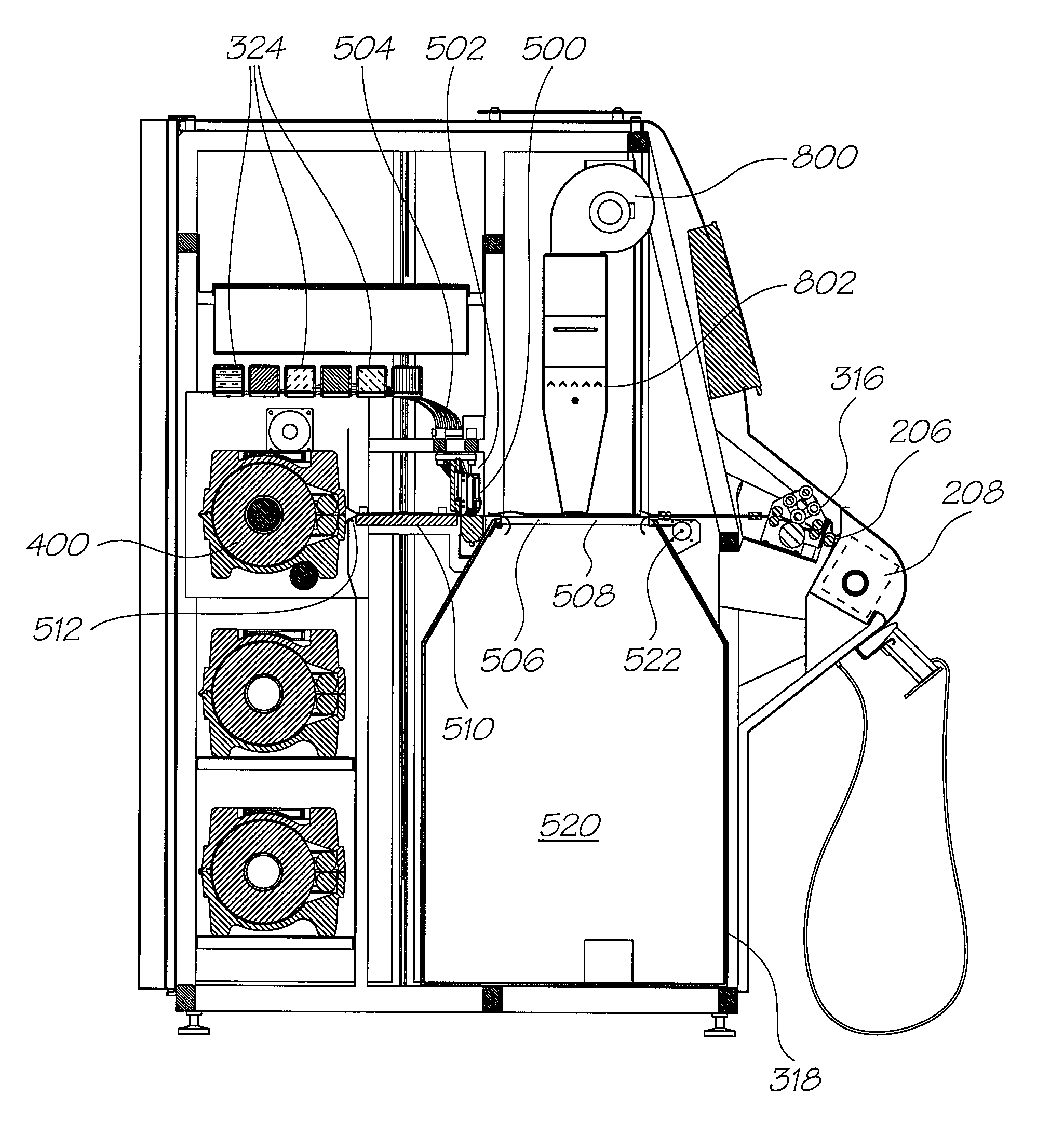

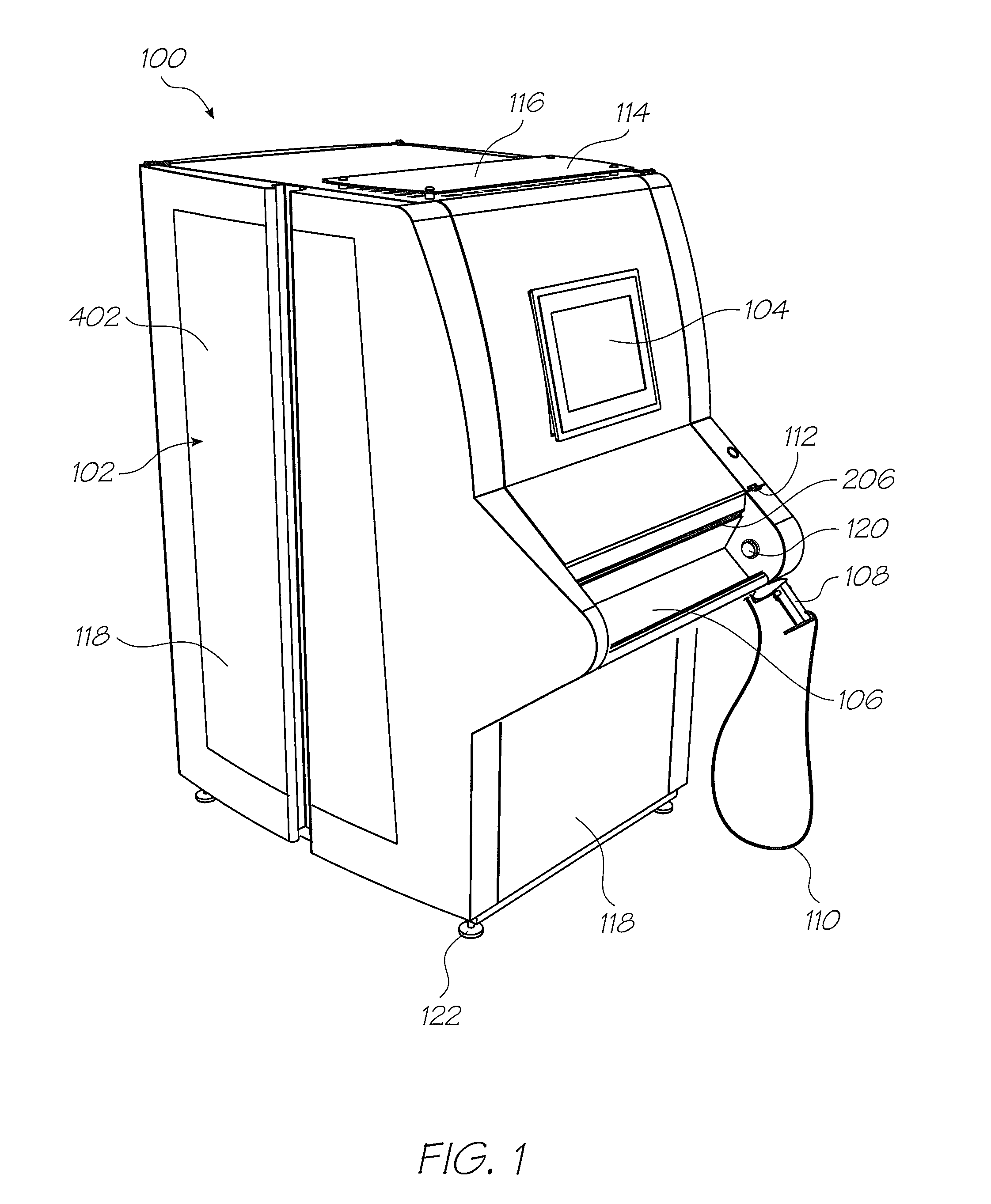

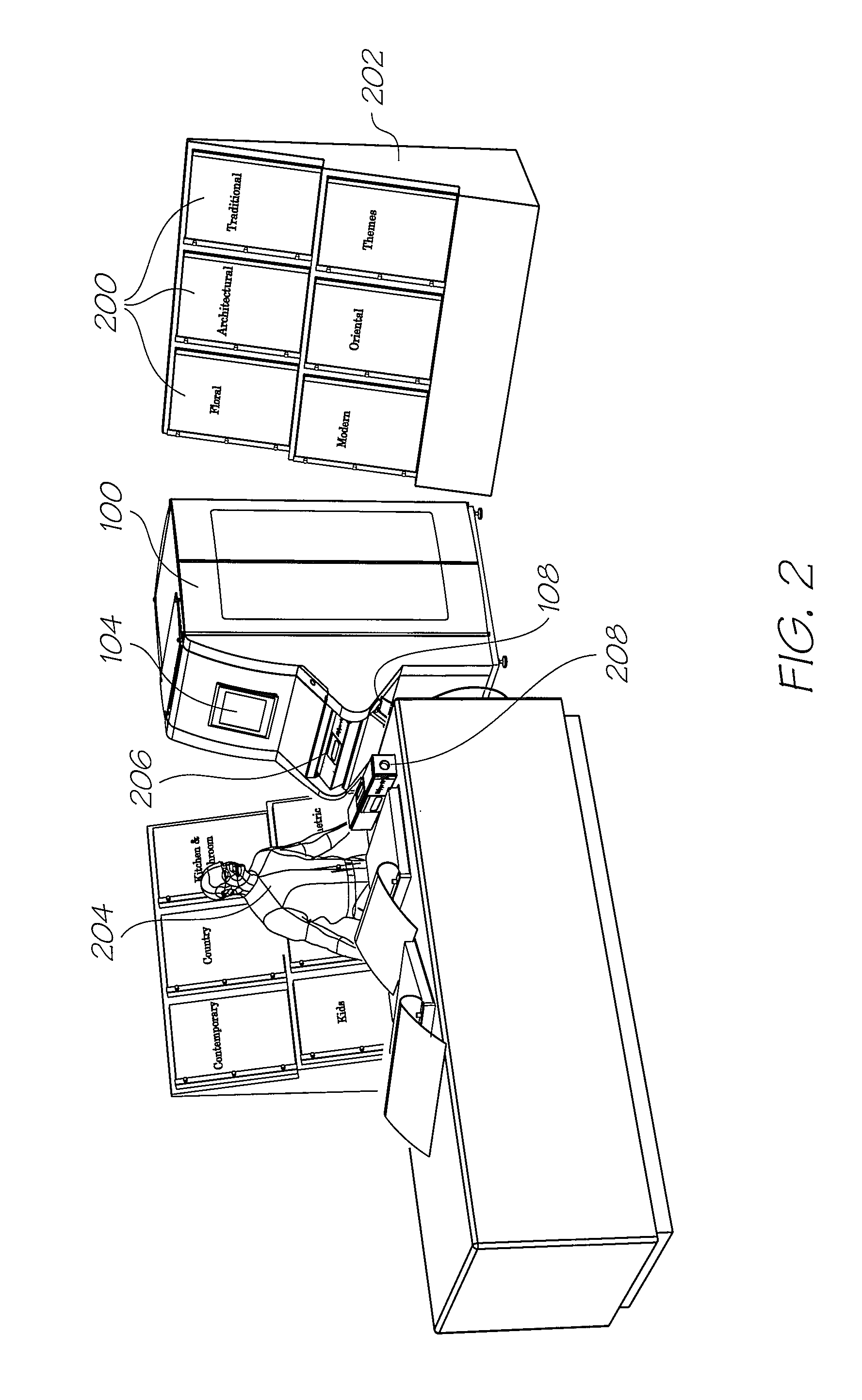

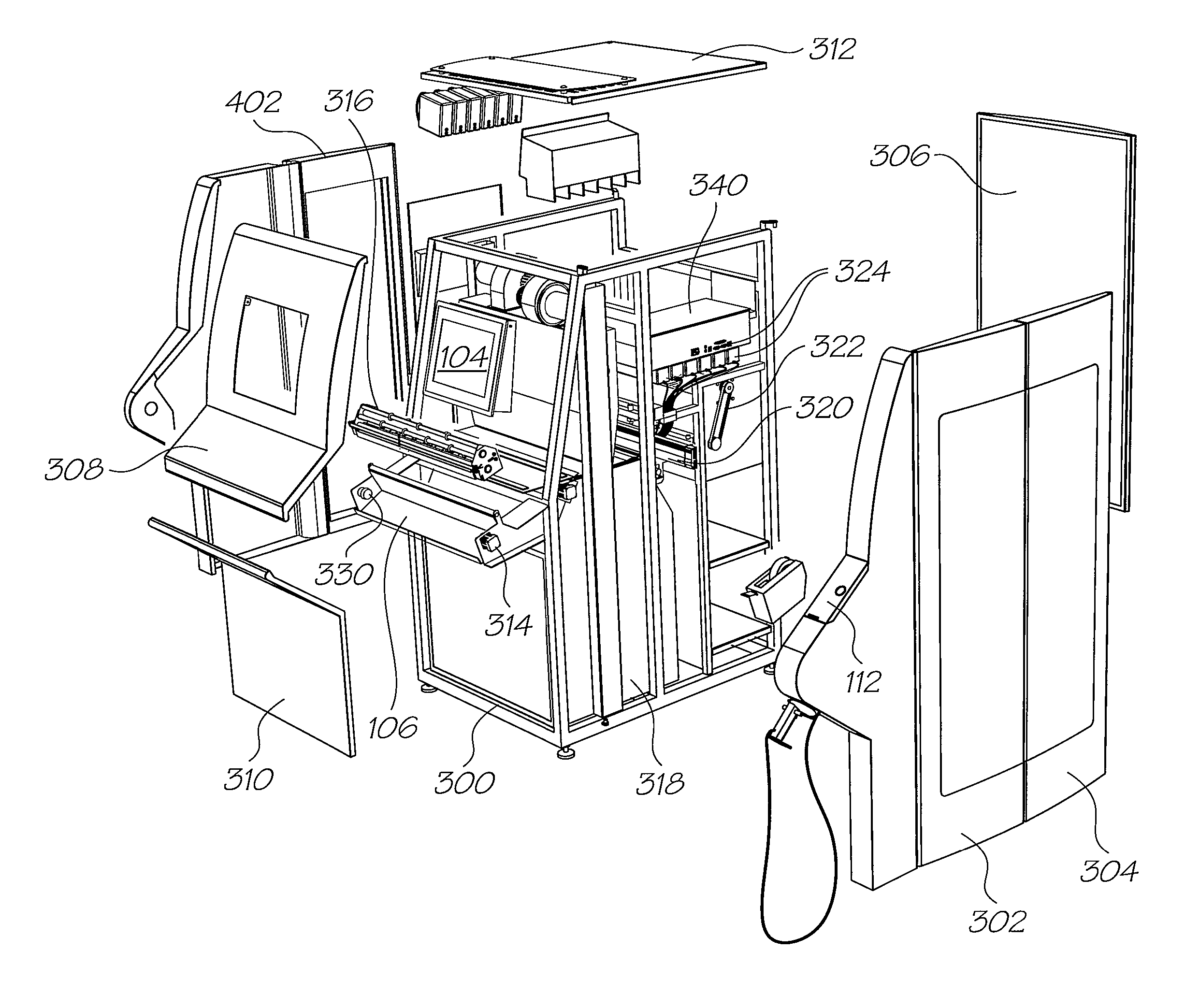

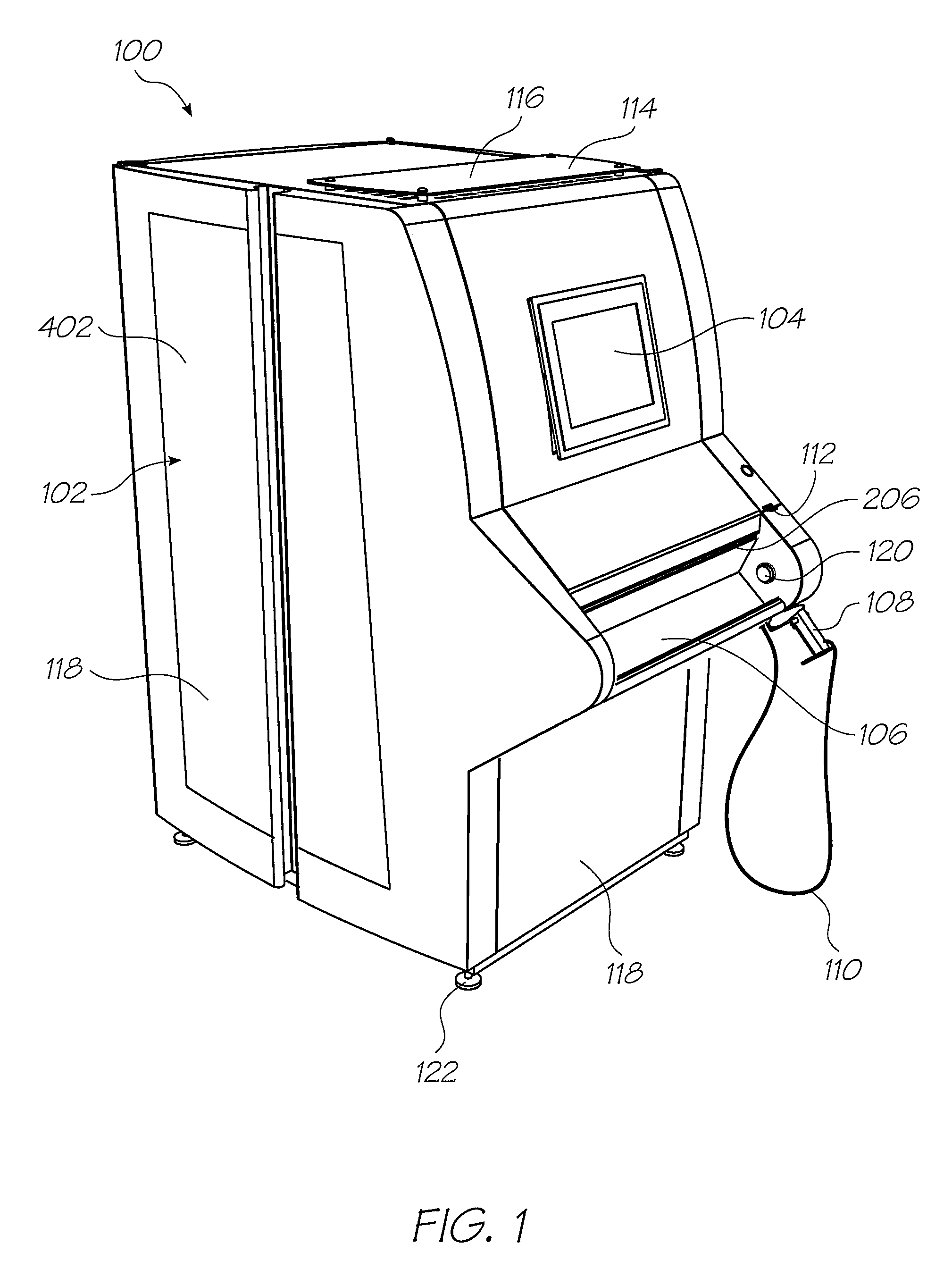

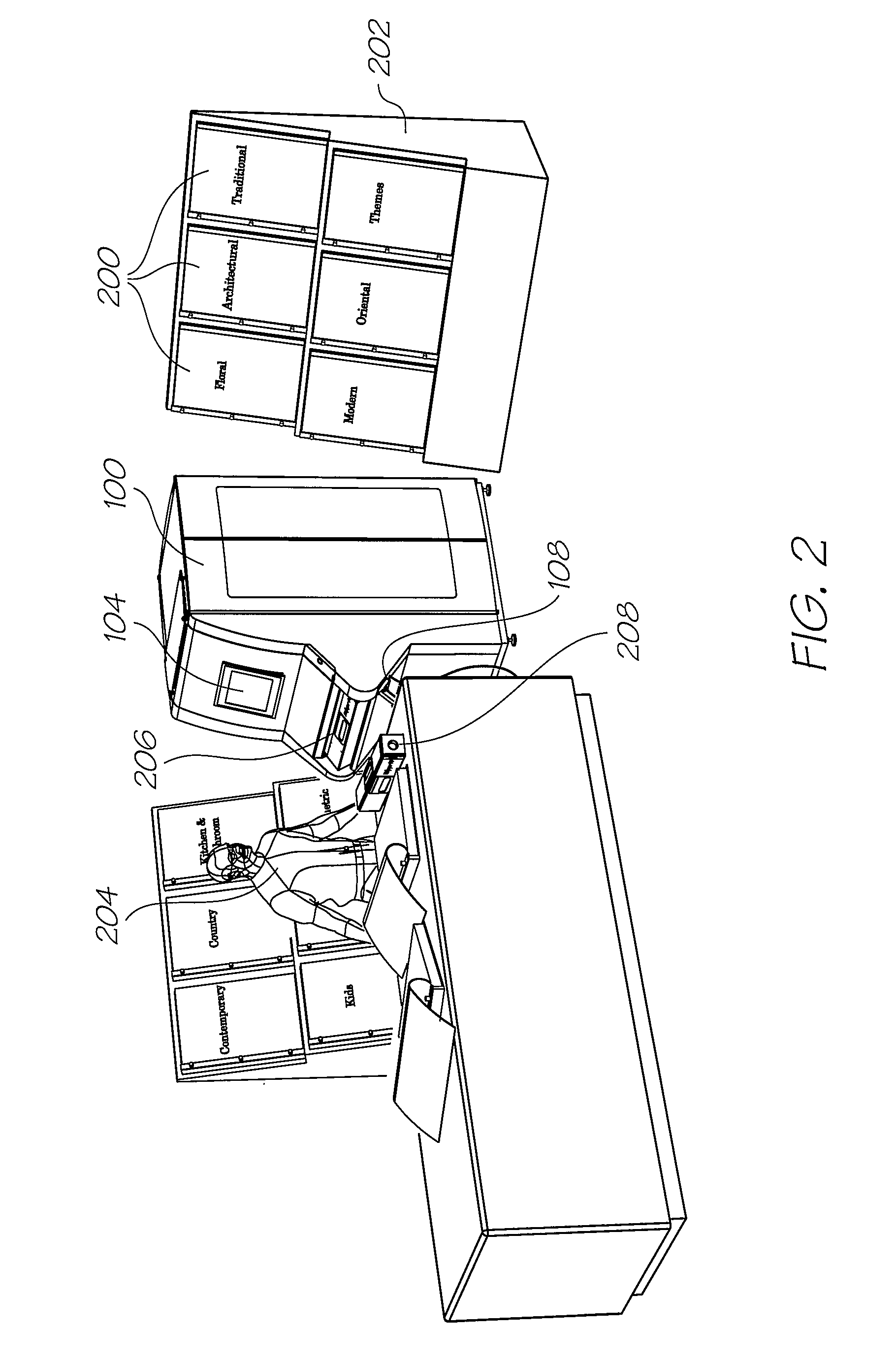

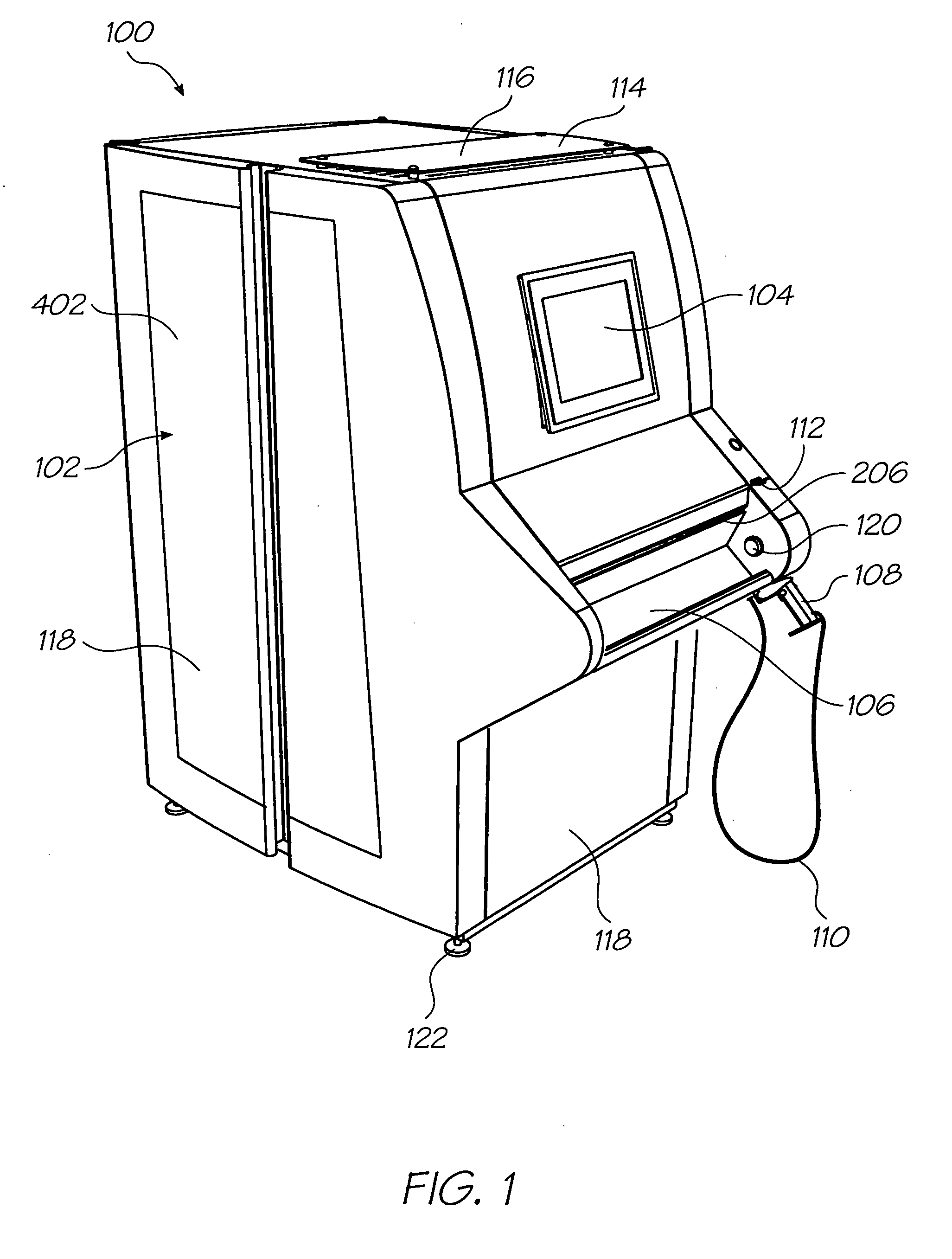

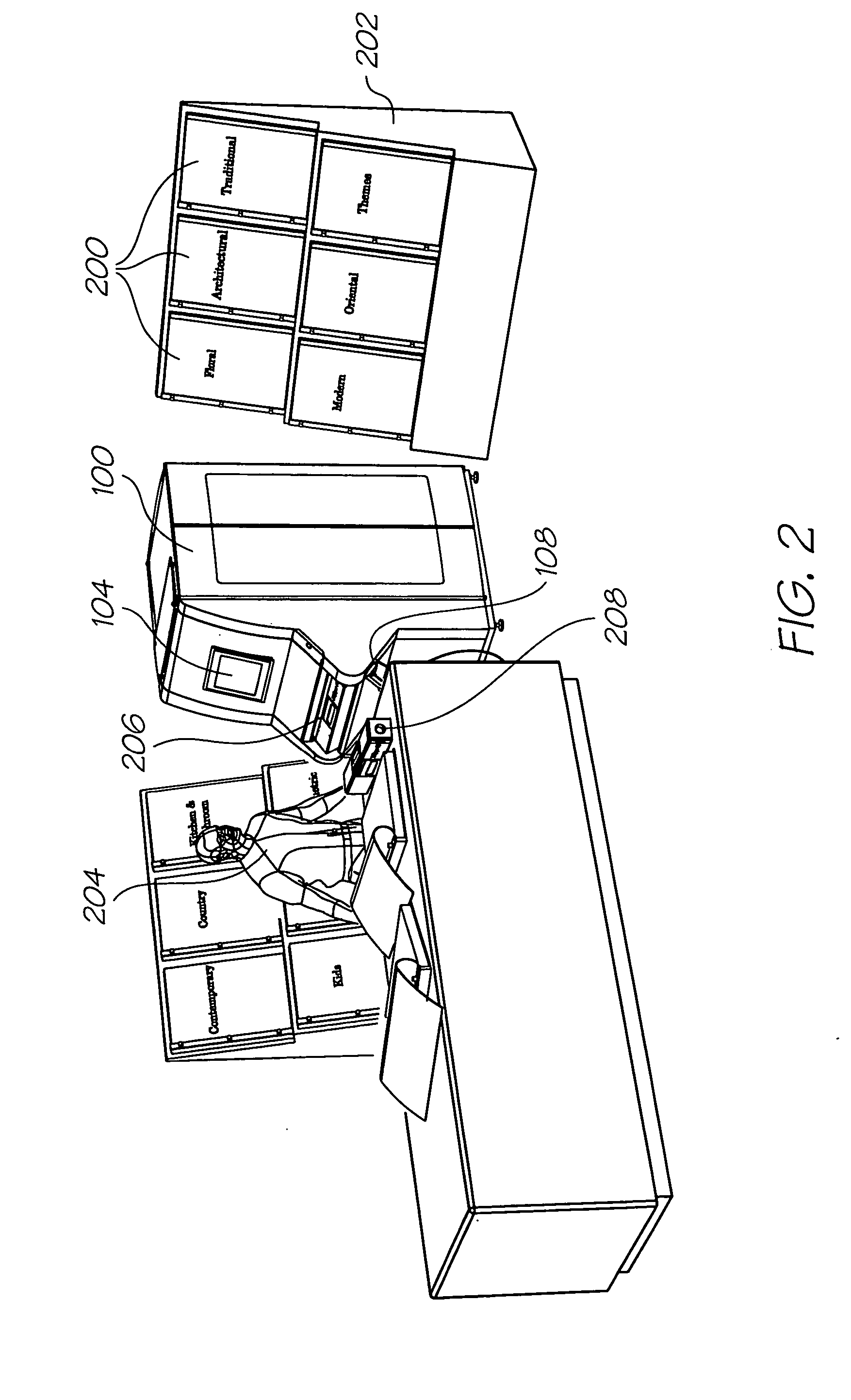

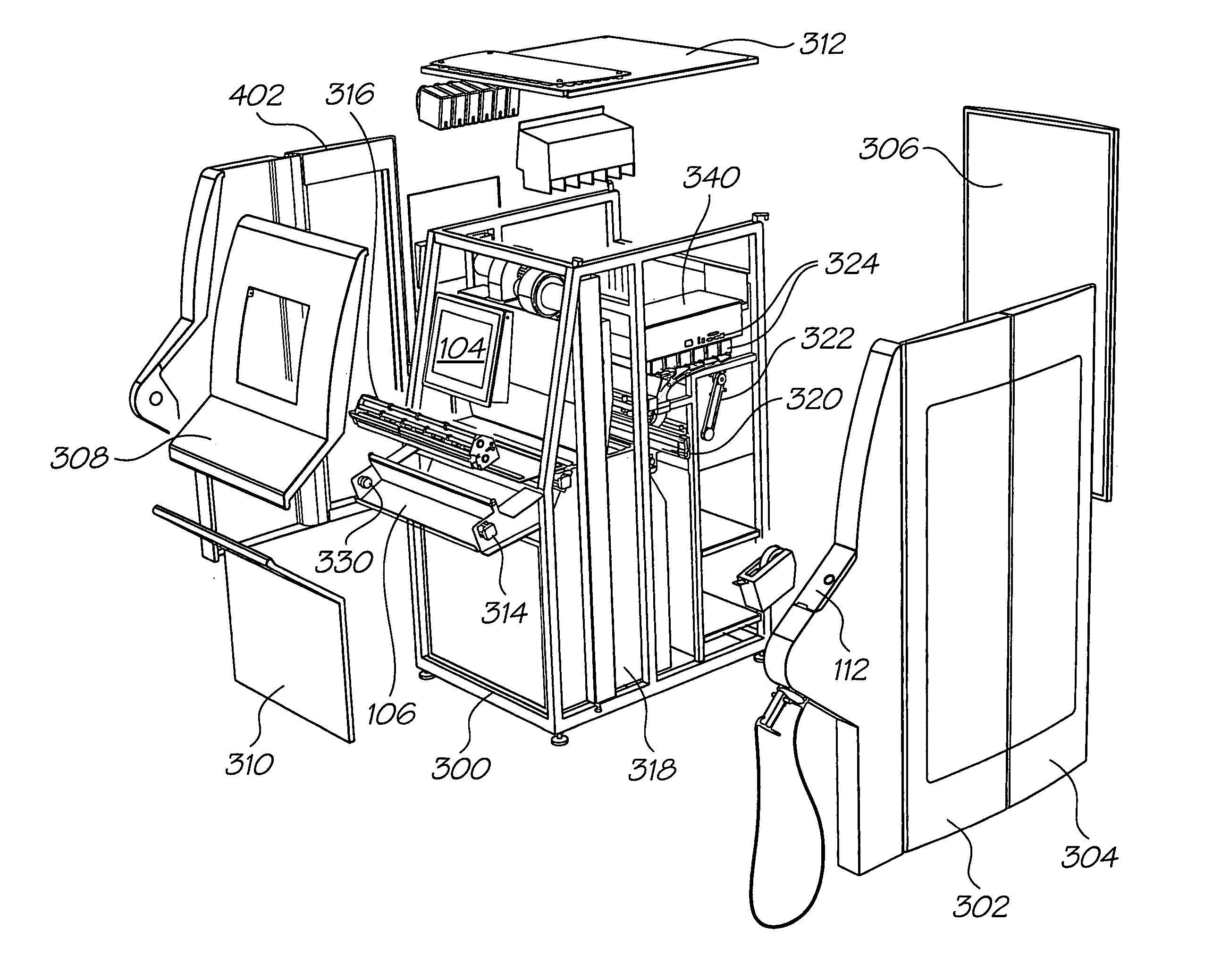

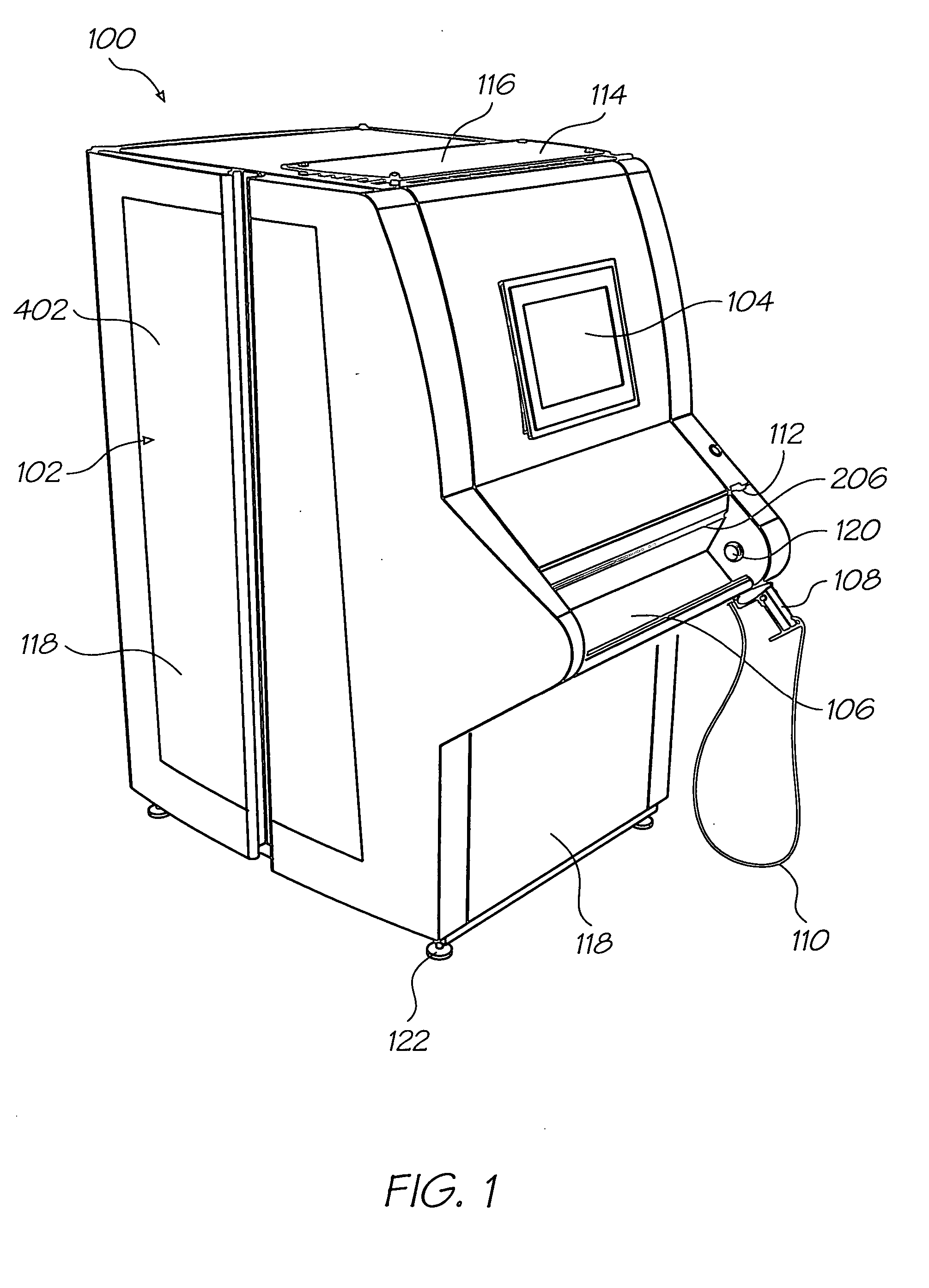

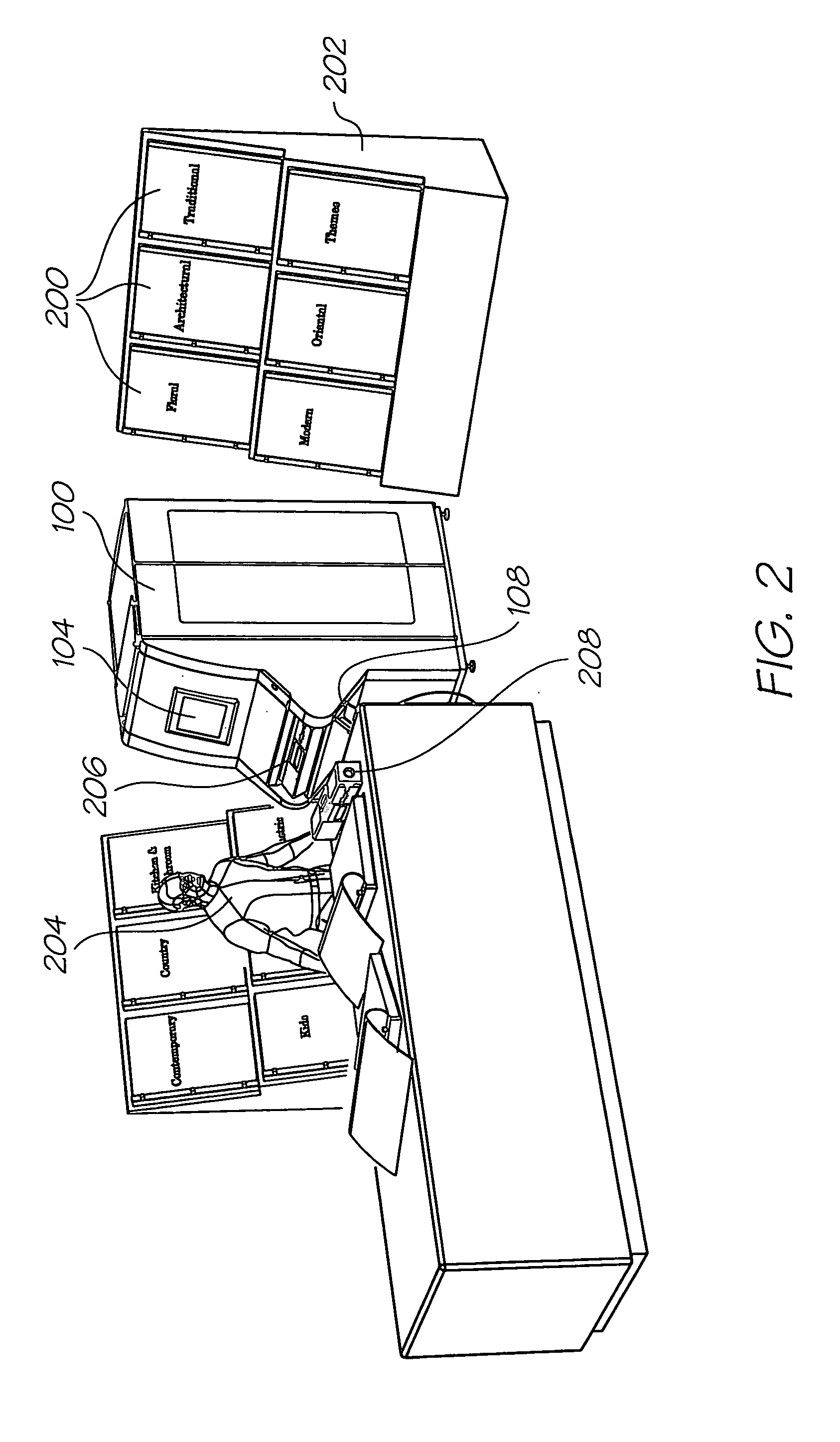

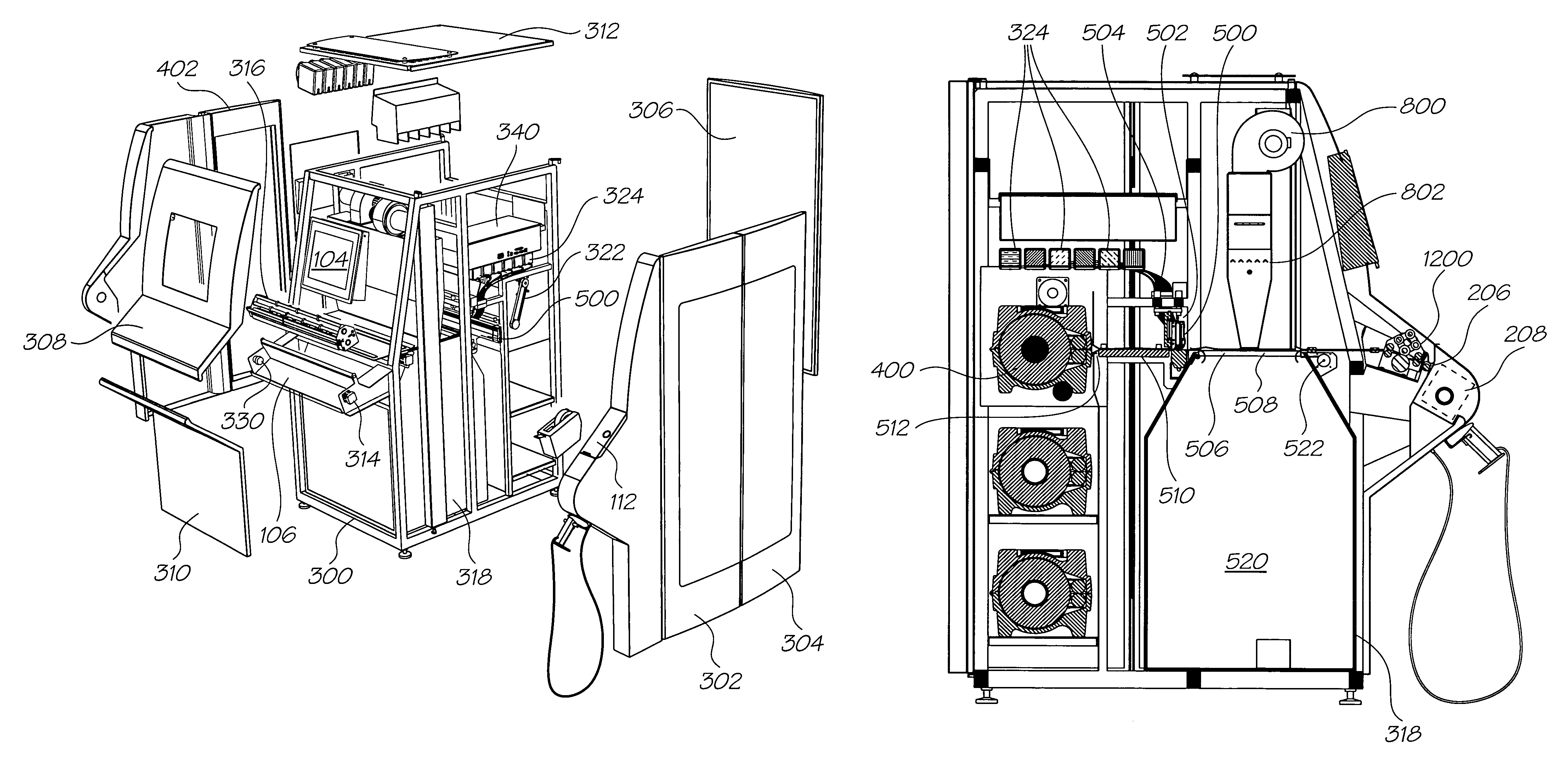

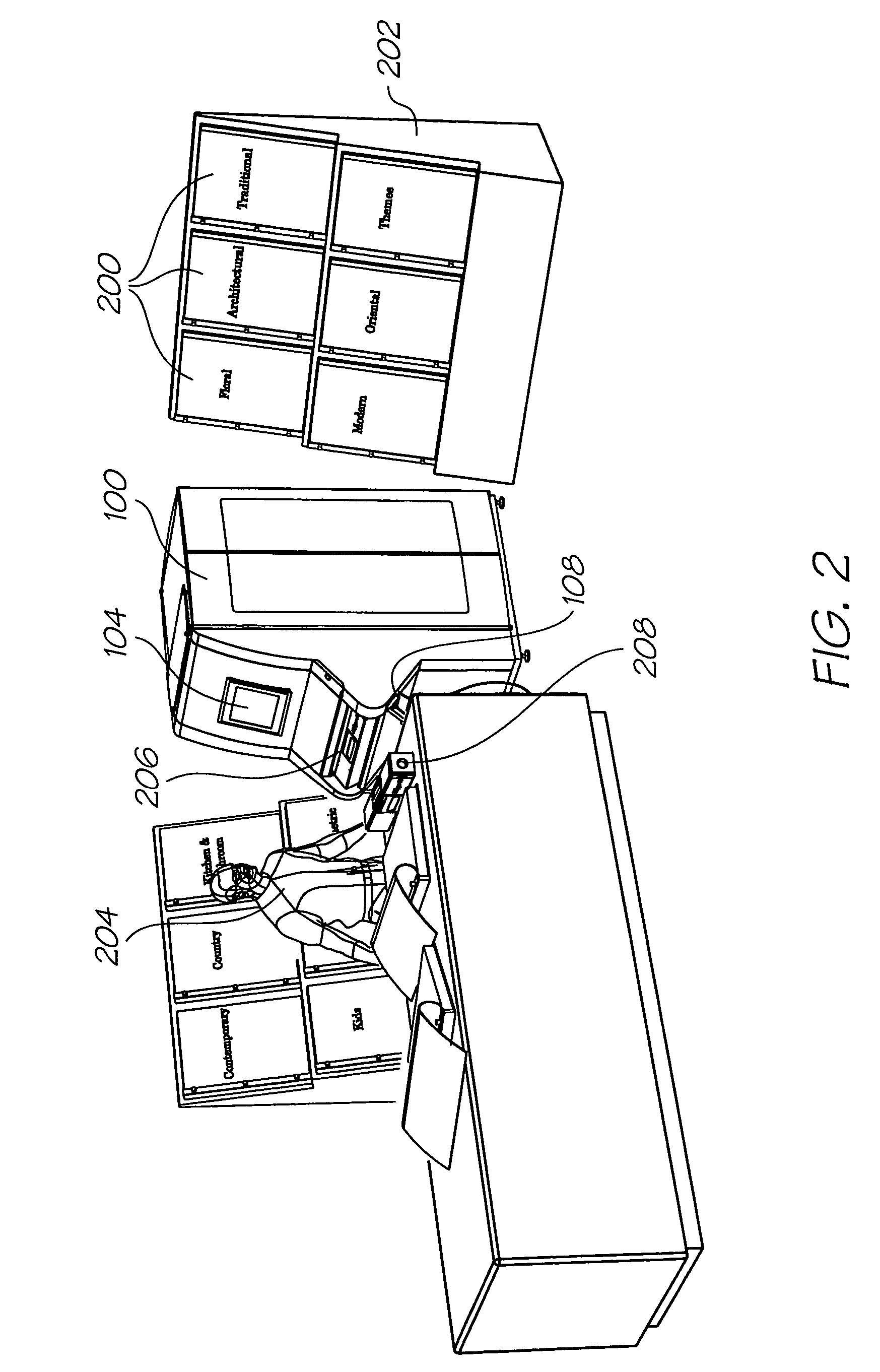

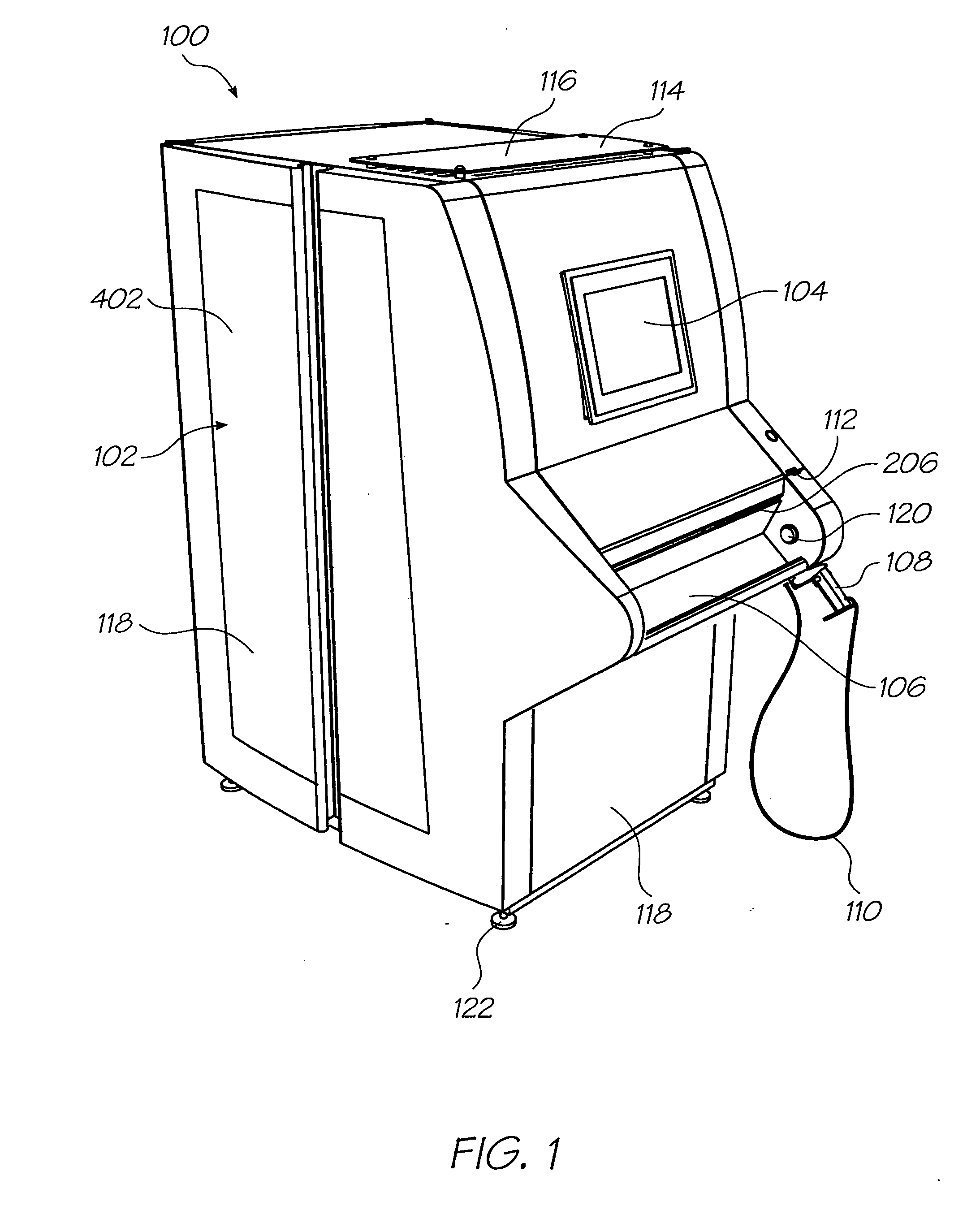

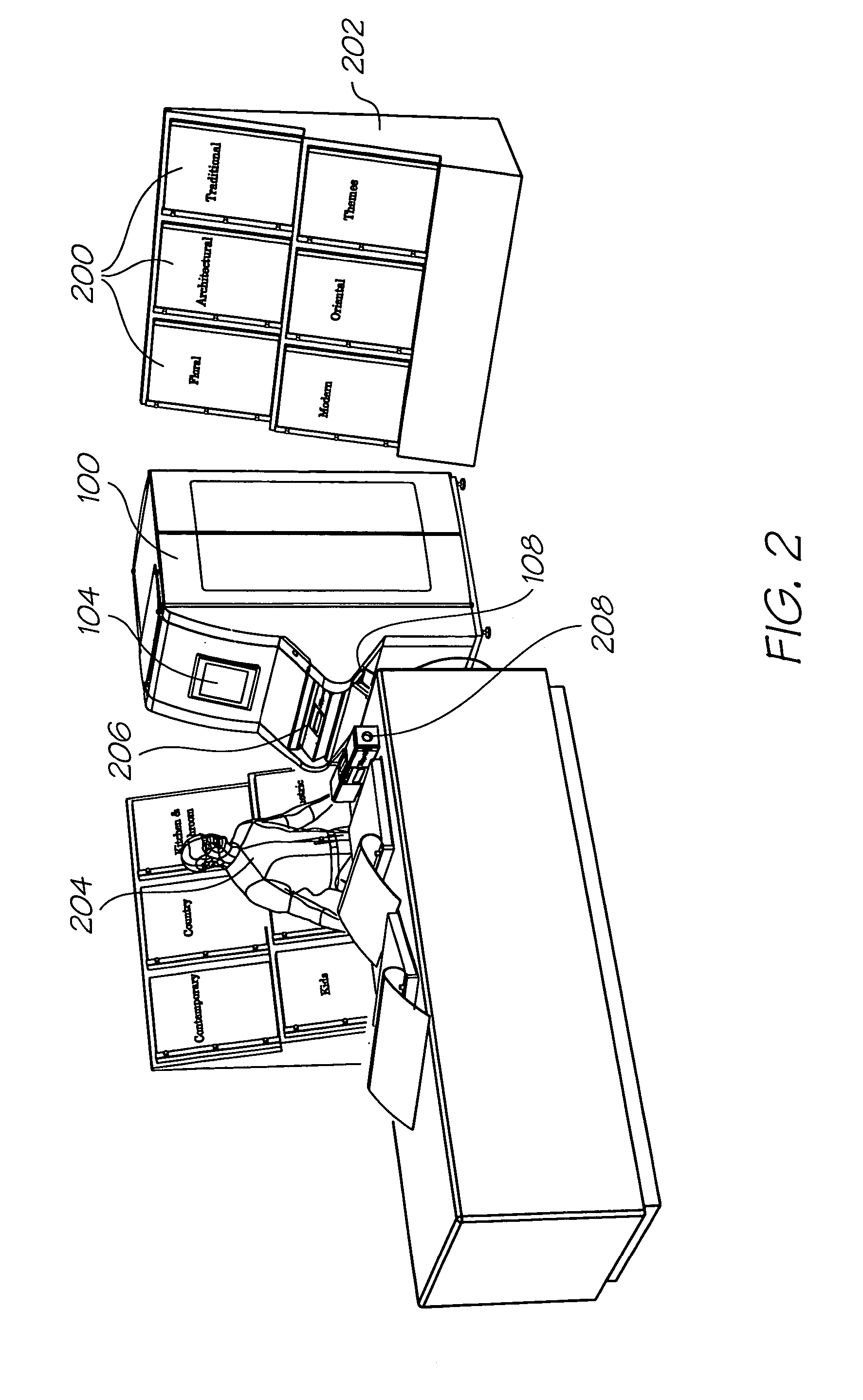

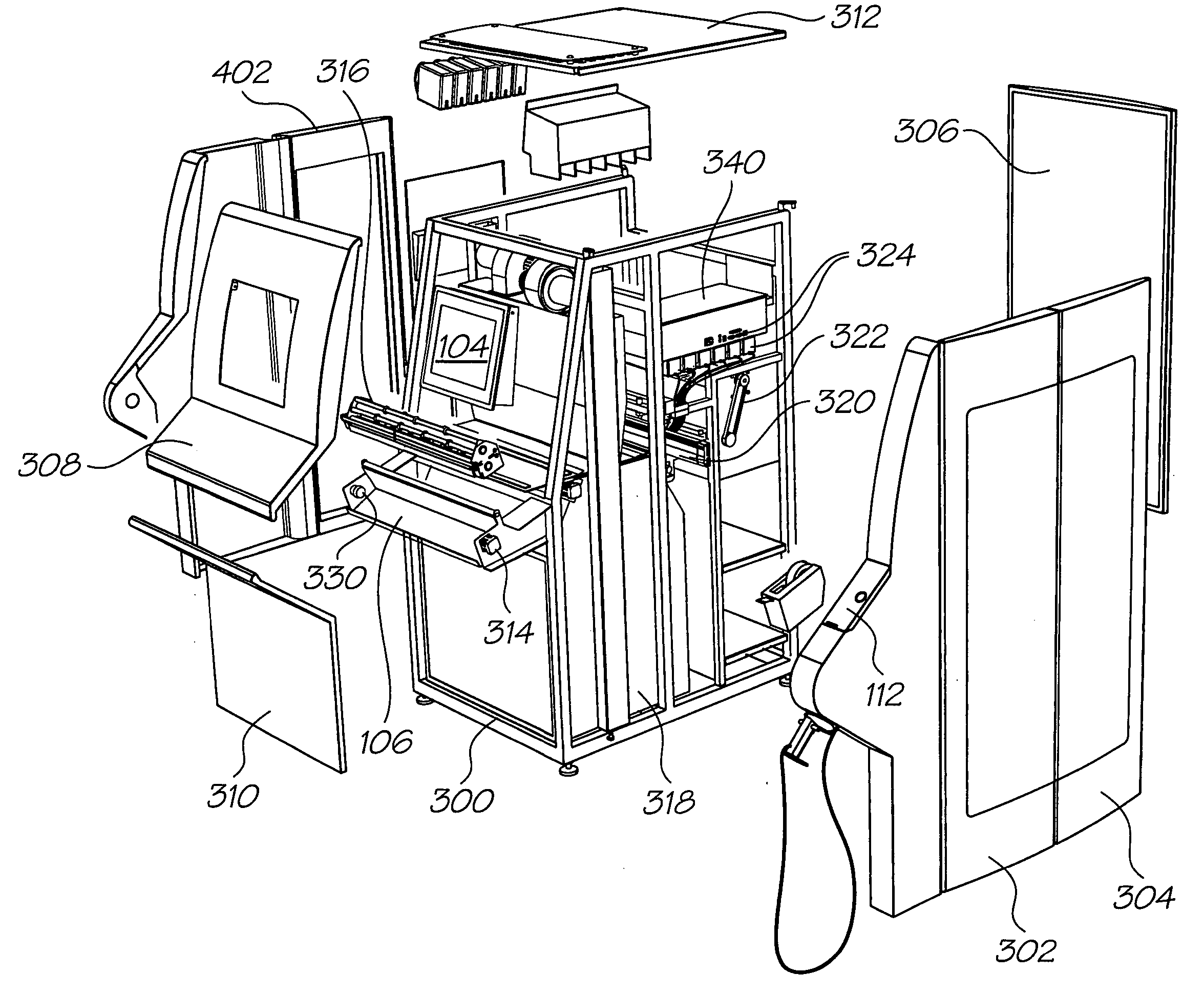

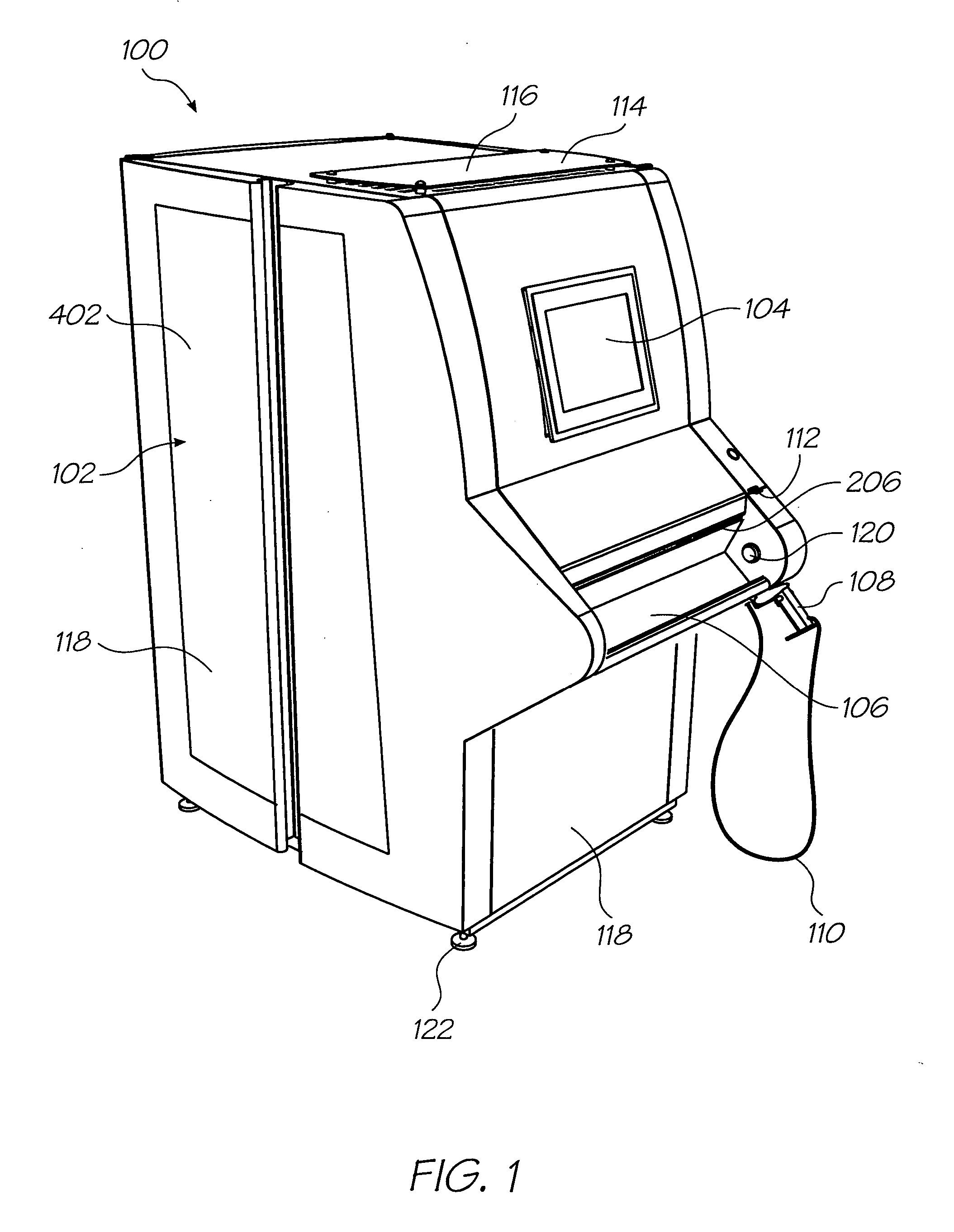

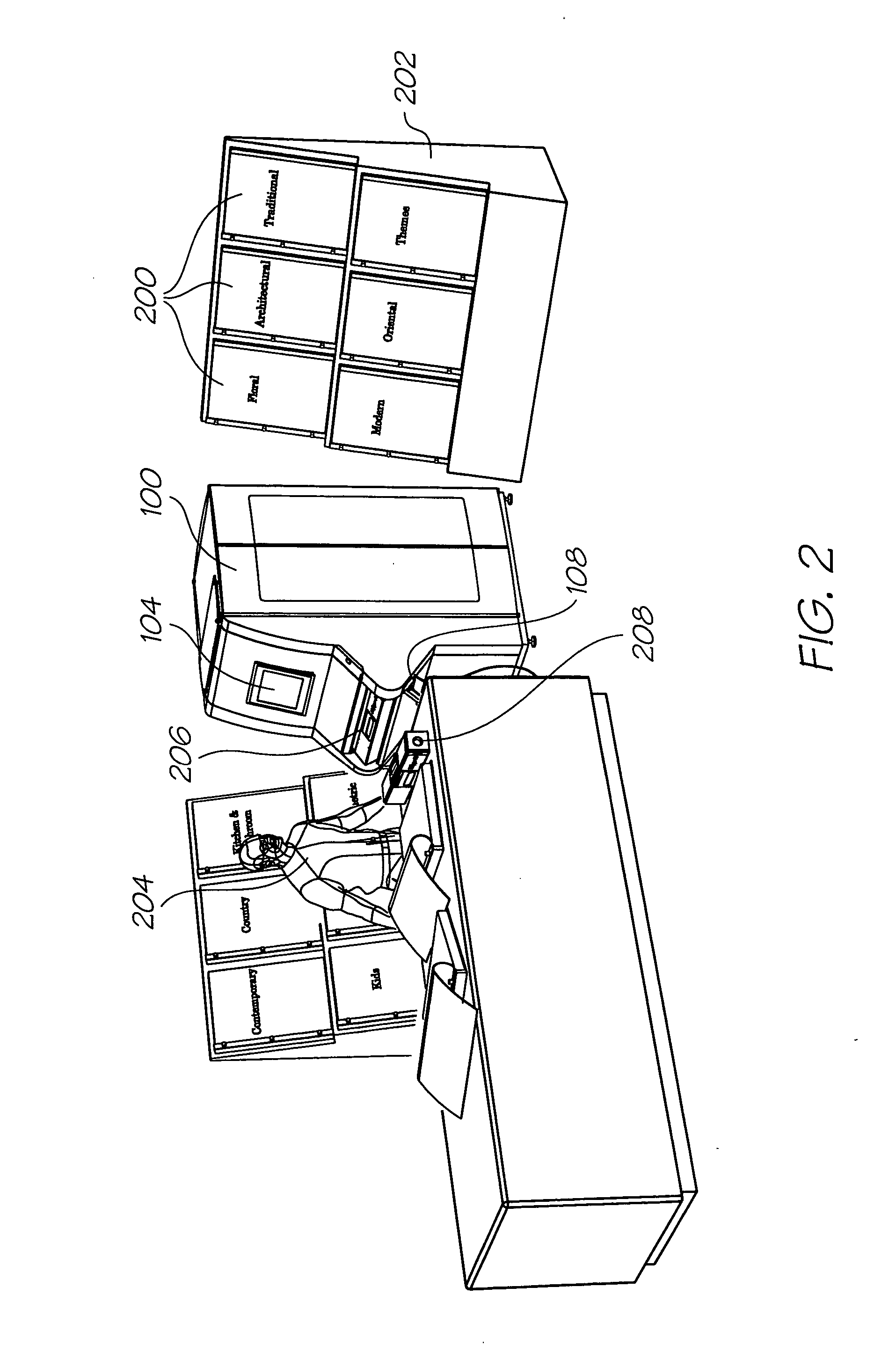

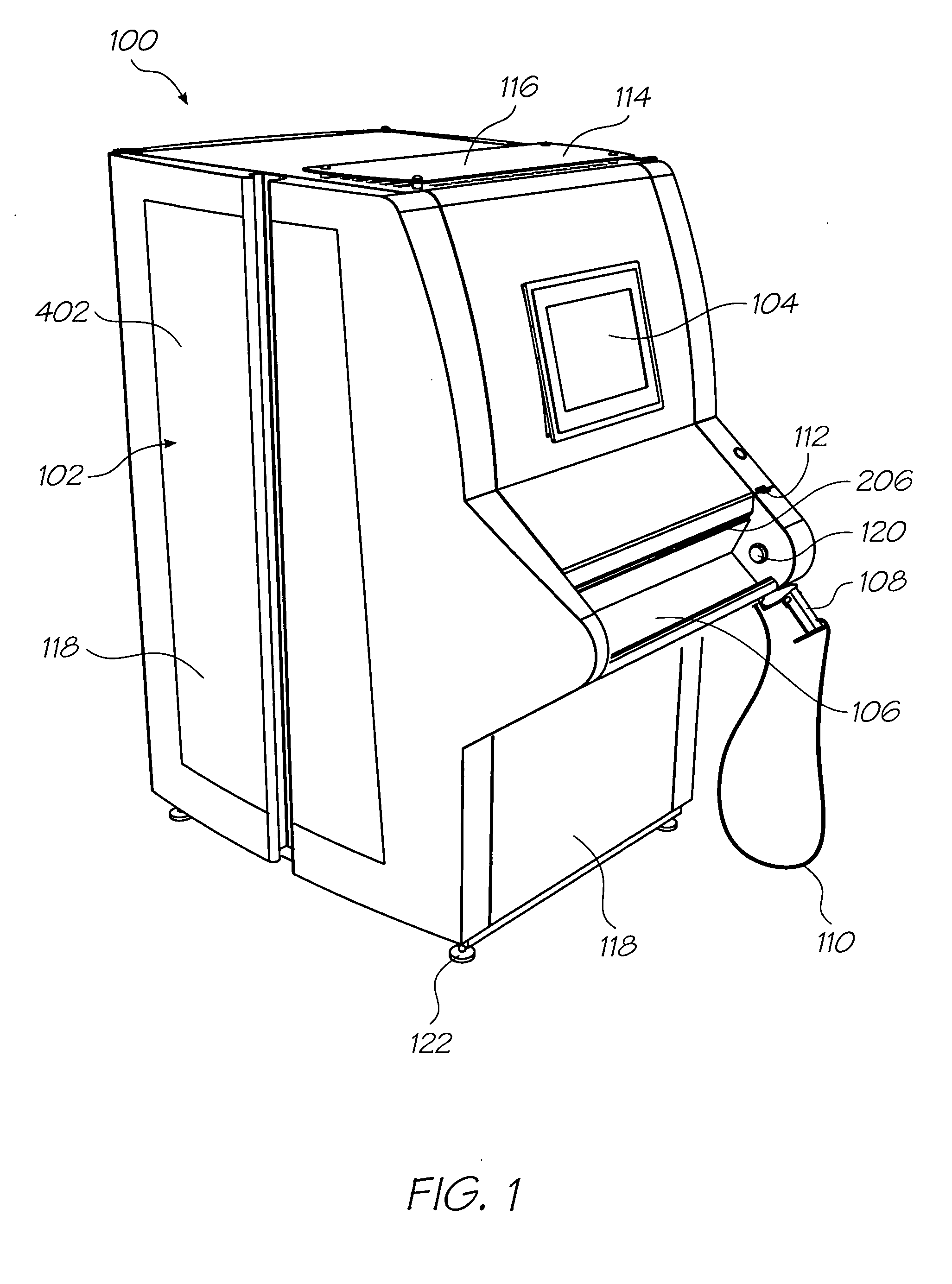

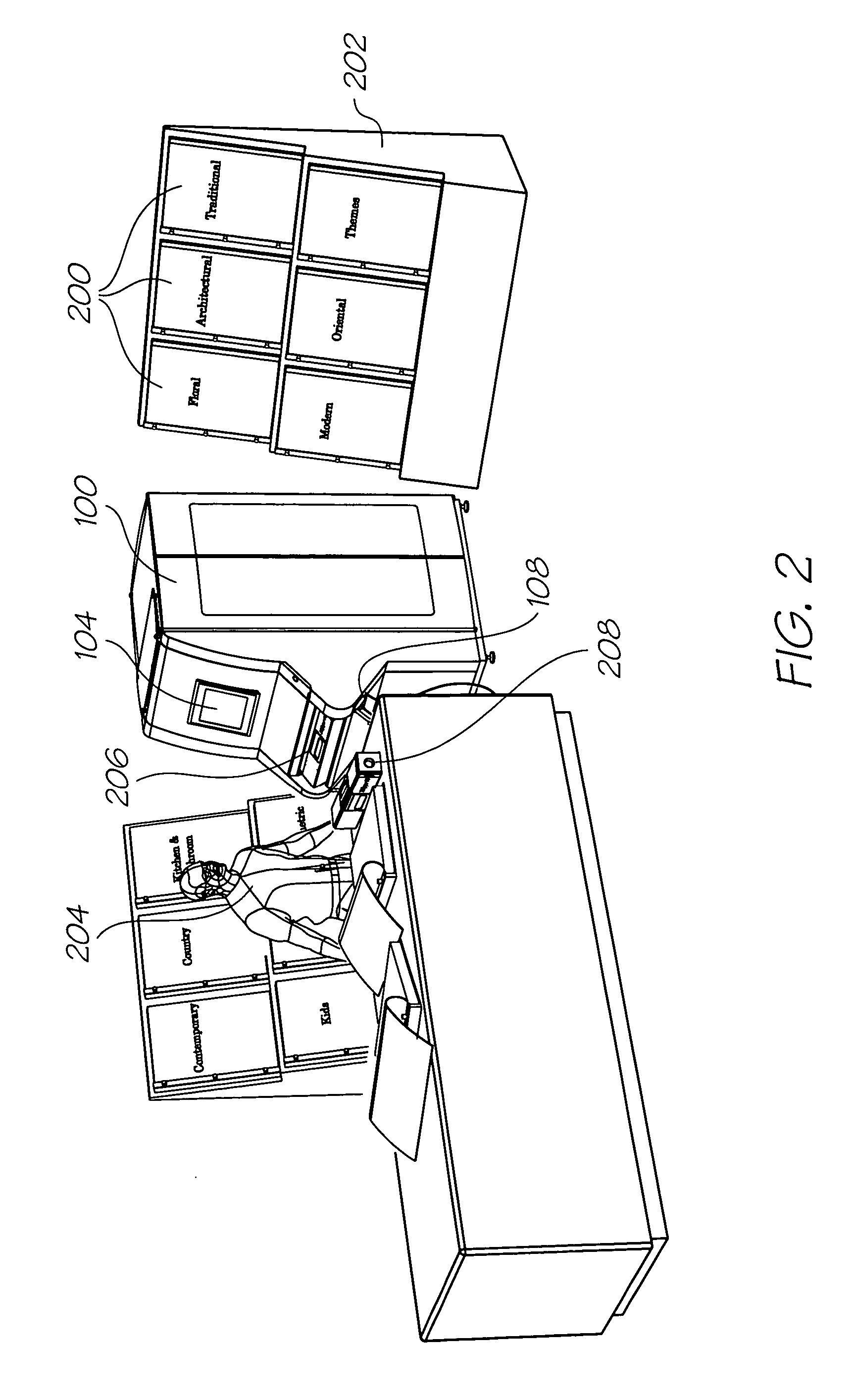

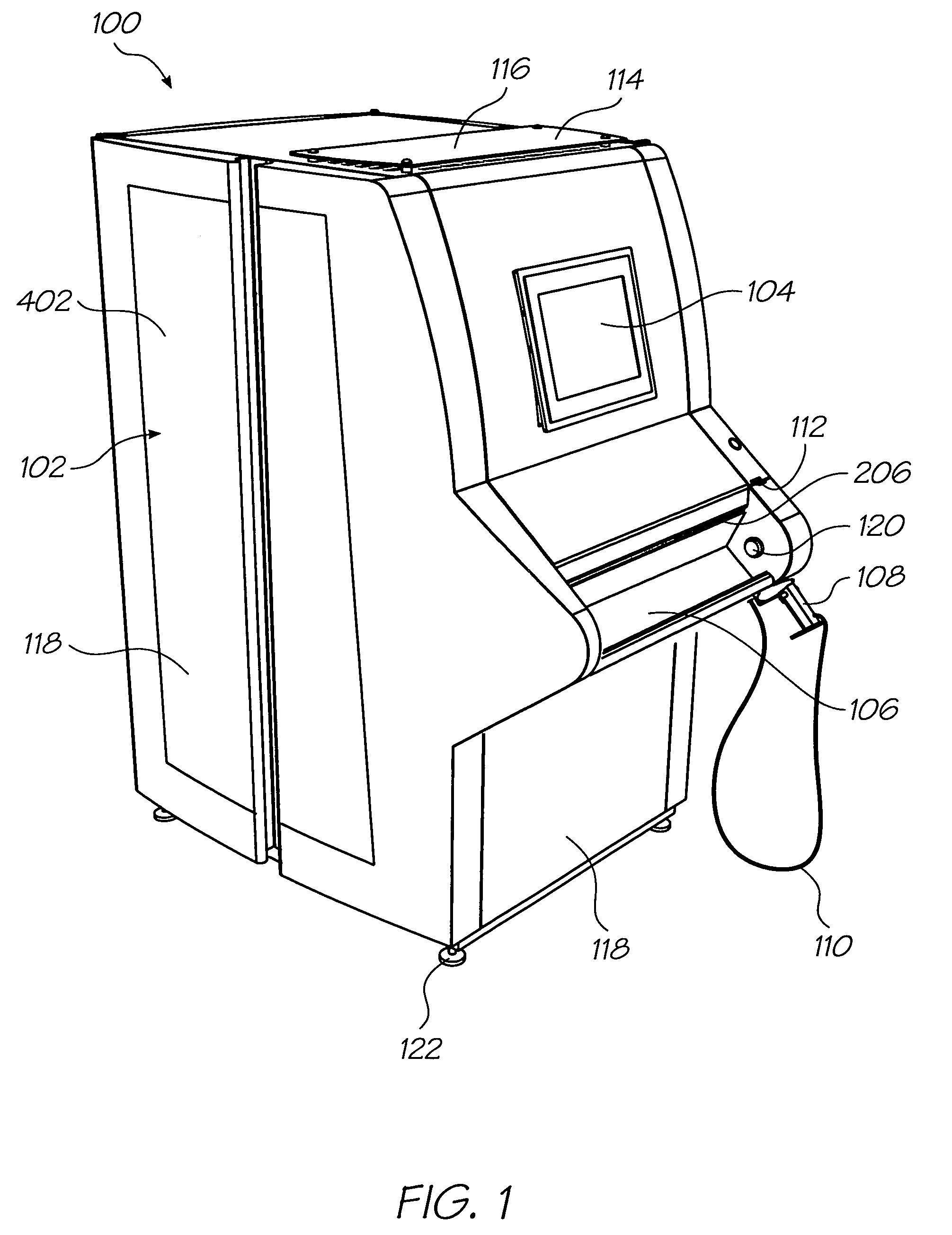

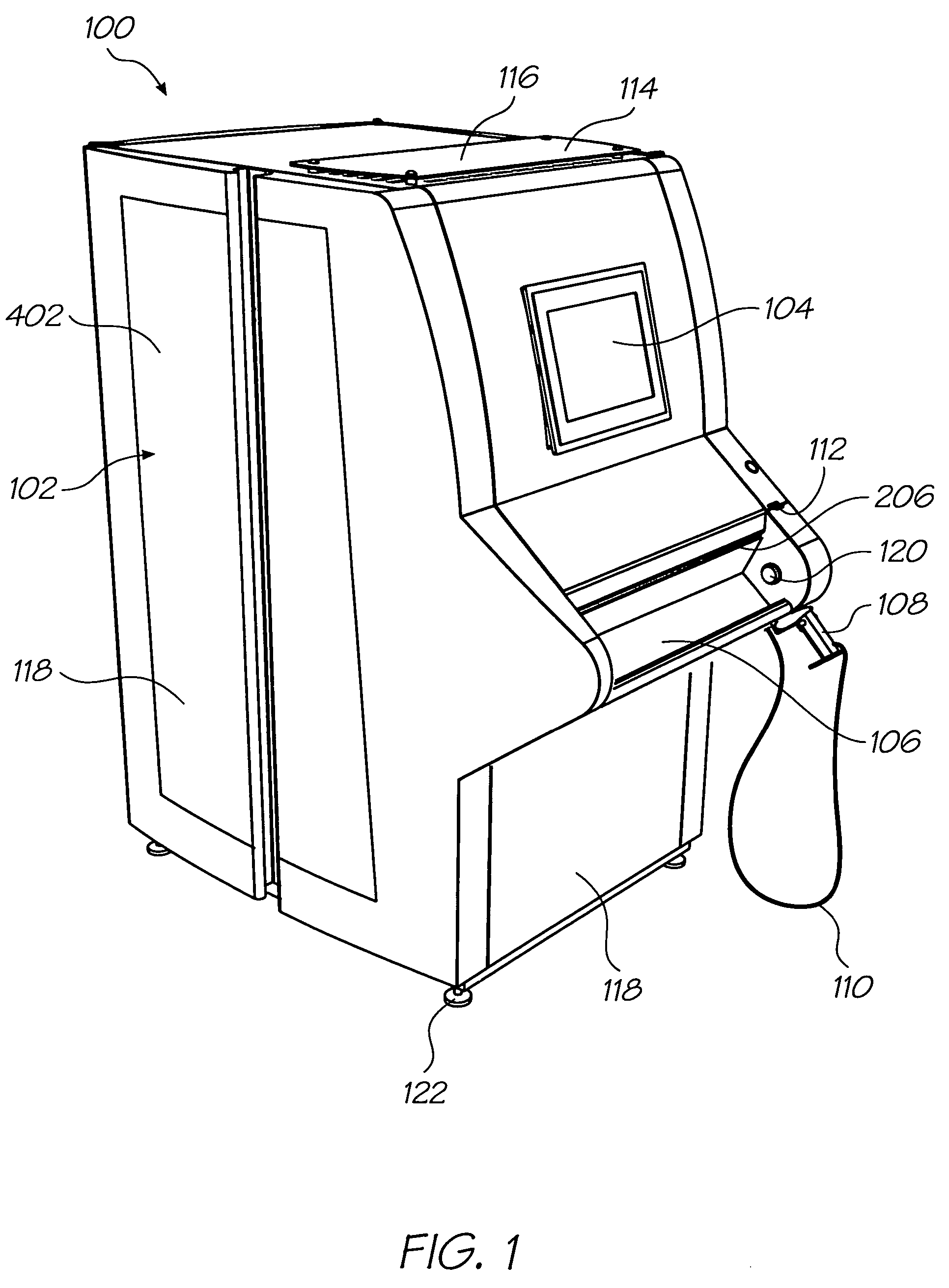

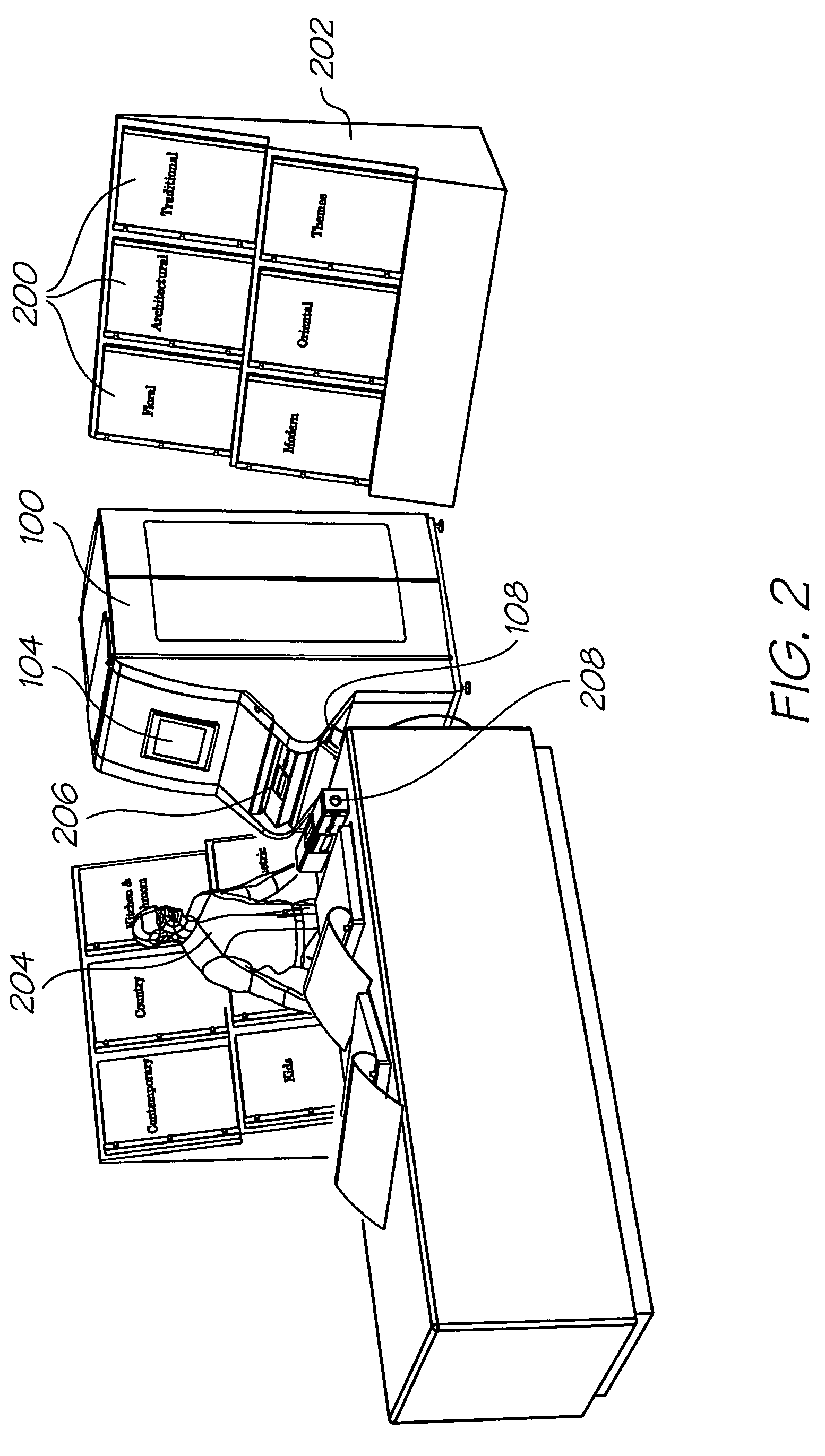

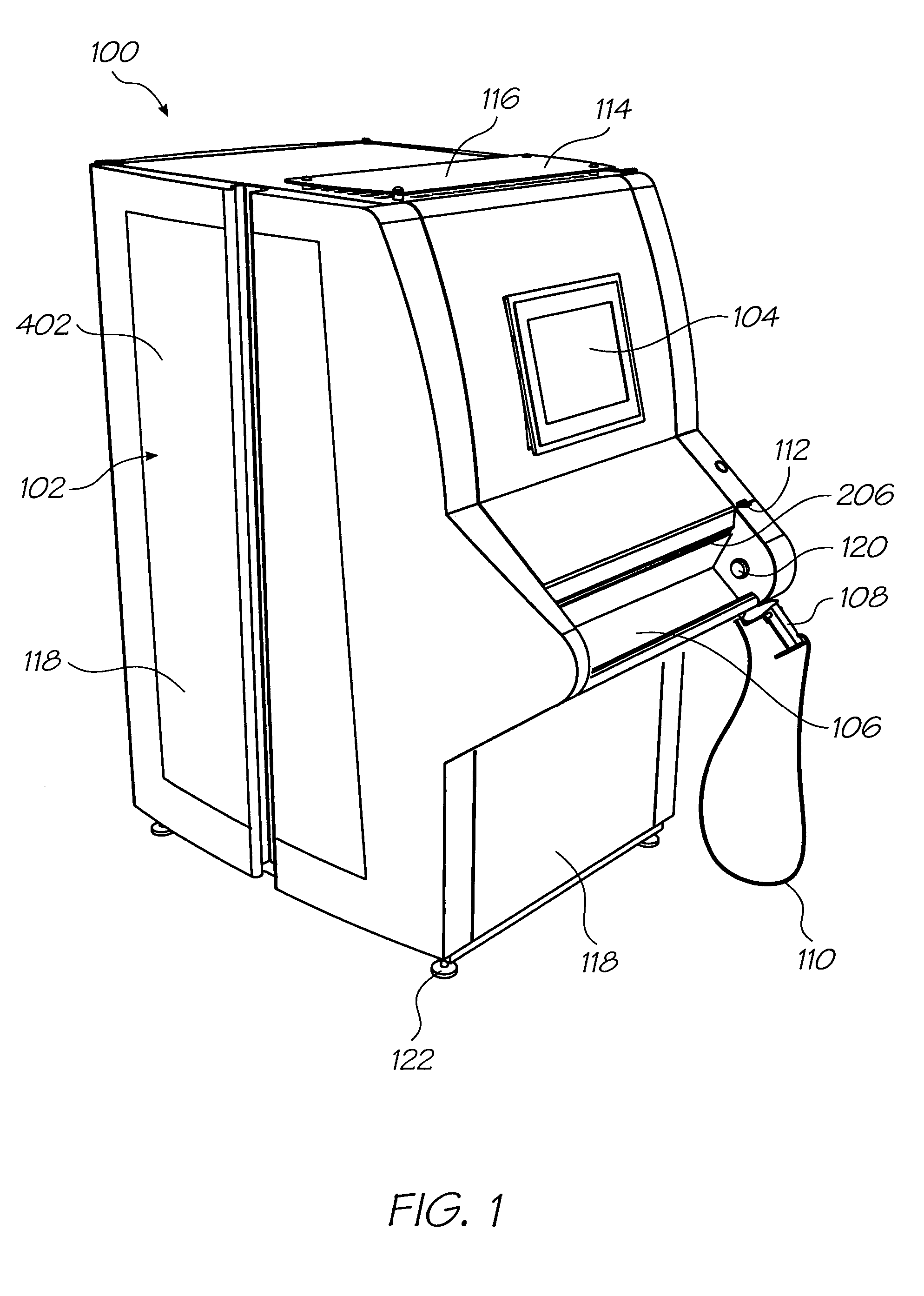

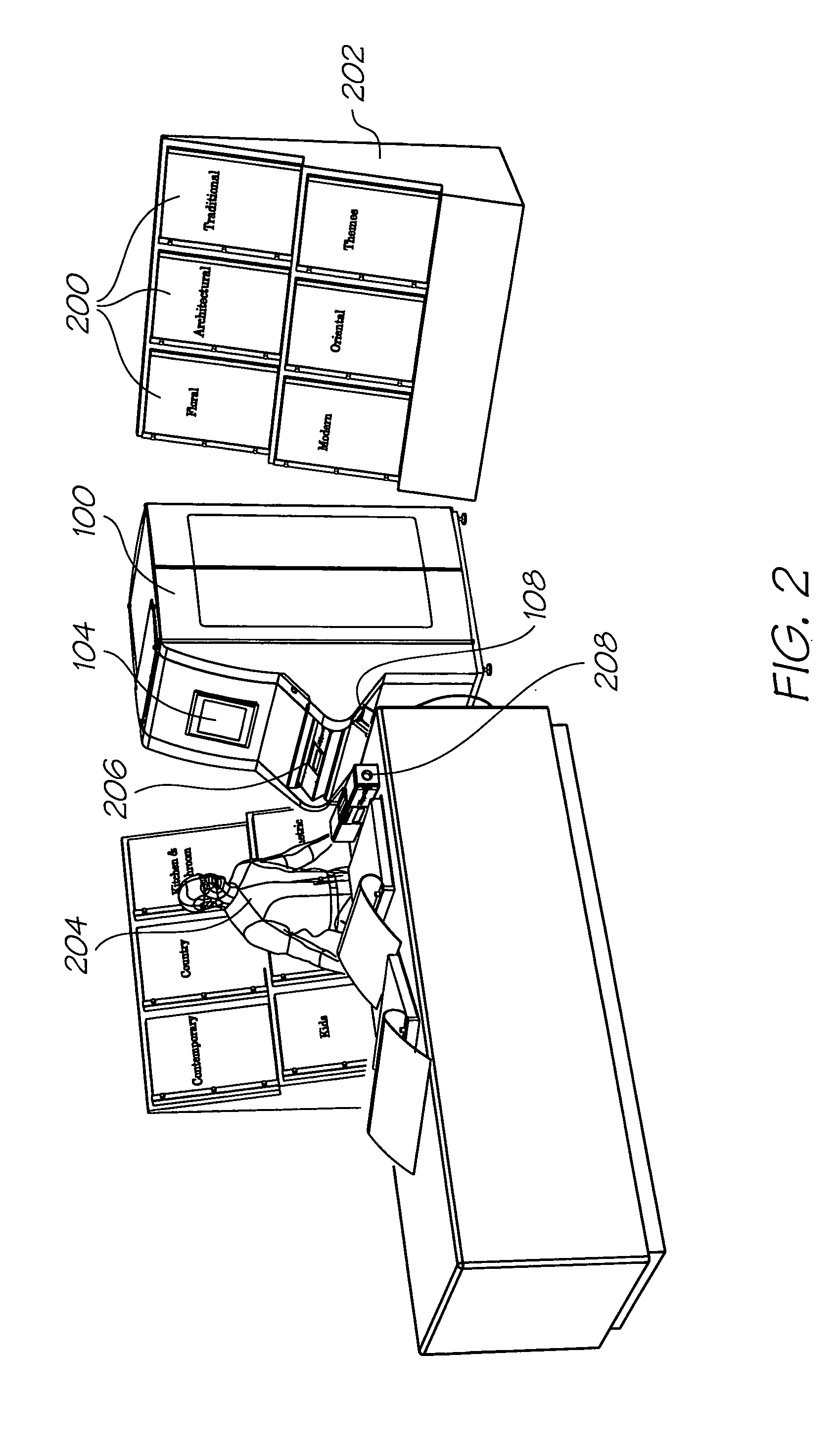

Self contained wallpaper printer

InactiveUS7237888B2Eliminate stock-out, stock-control/ordering and stock obsolesces issuesEliminate inventoryPattern printingTypewritersWallpaper printerEngineering

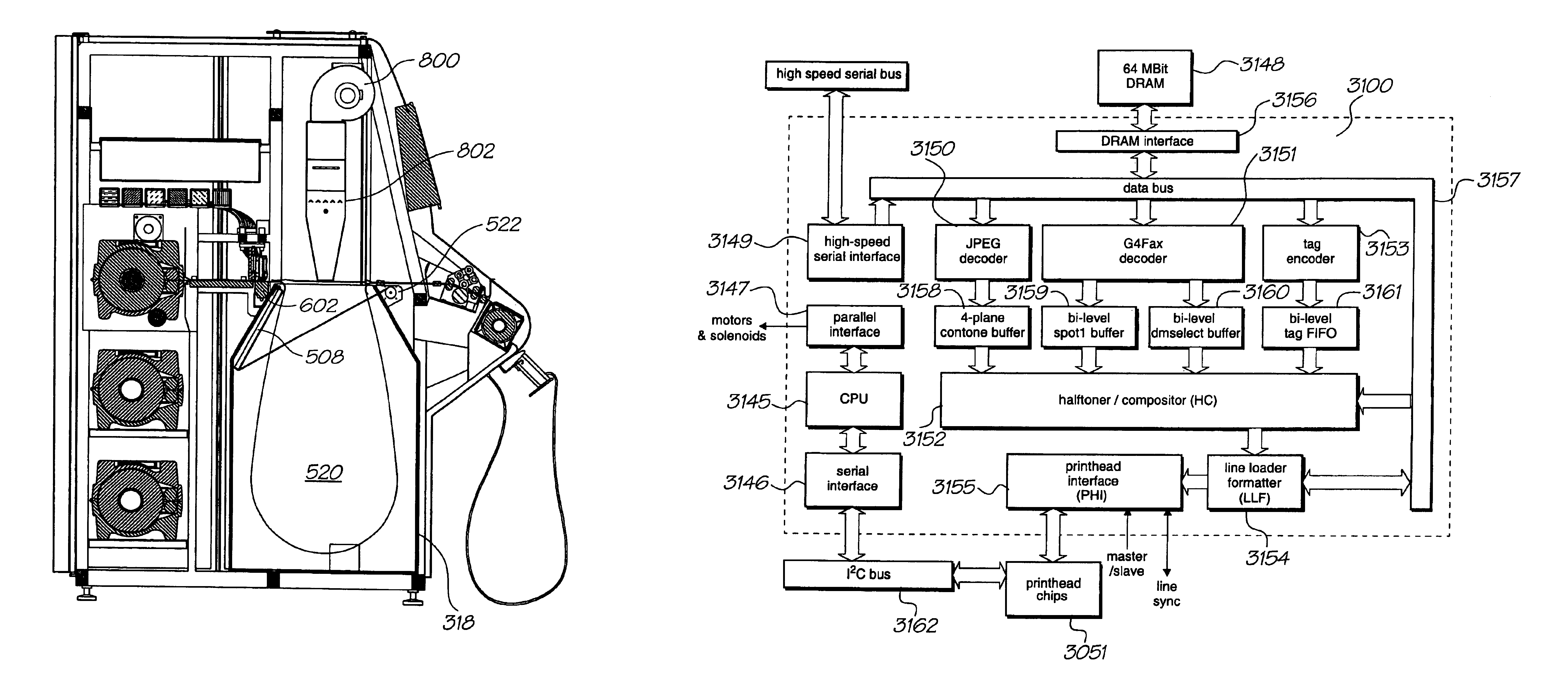

A self contained printer produces rolls of wallpaper on demand. The unit is contained in a cabinet through which runs a media path. The path extends from a replaceable media cartridge a to a winding area which holds a customer tote. A full width digital color printhead is located internally and across the media path. The printer's processor accepts operator inputs which are used to configure the printer for producing a particular roll.

Owner:MEMJET TECH LTD +1

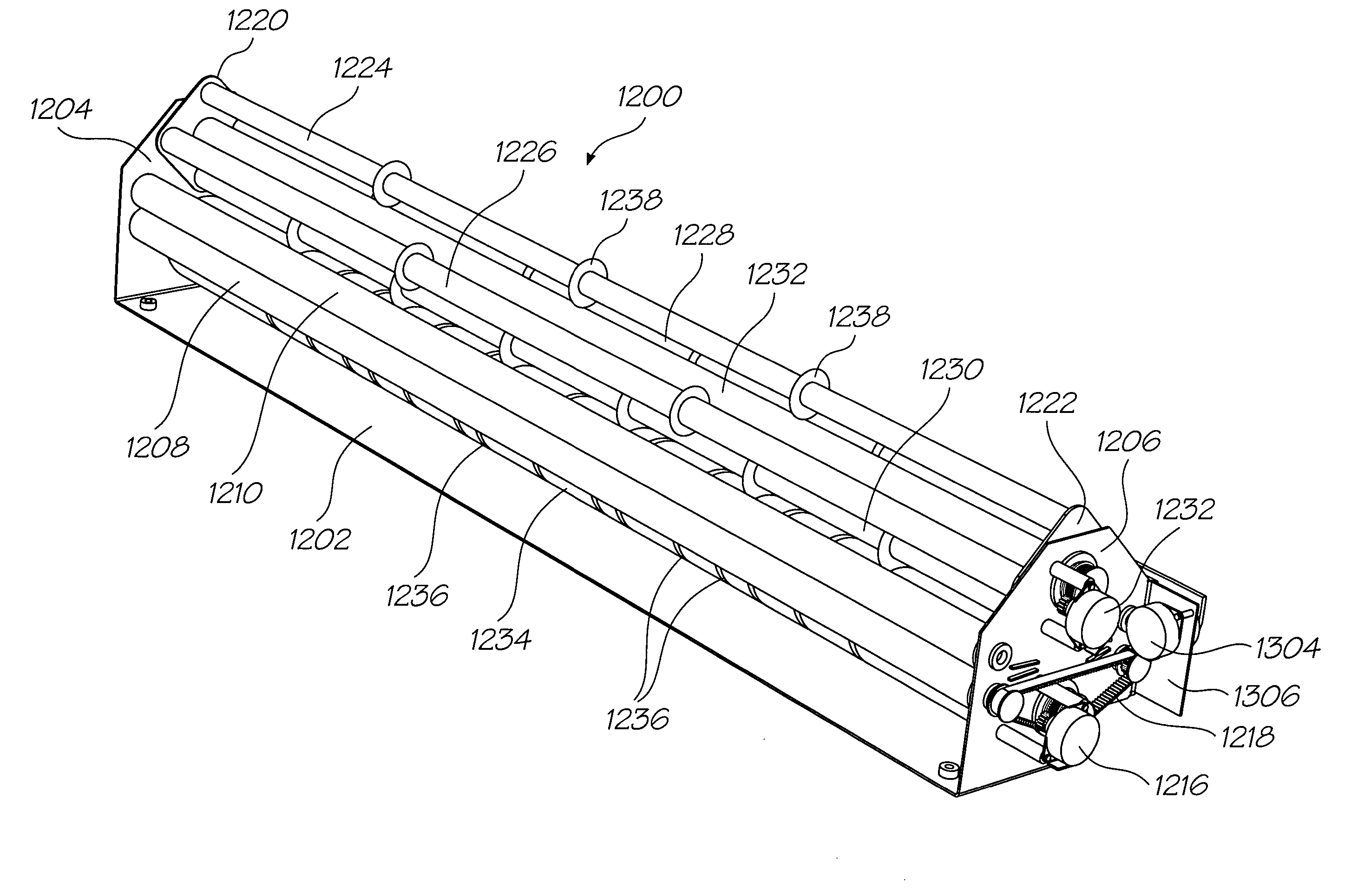

Combined cutter and slitter module for a printer

Owner:SILVERBROOK RES PTY LTD +1

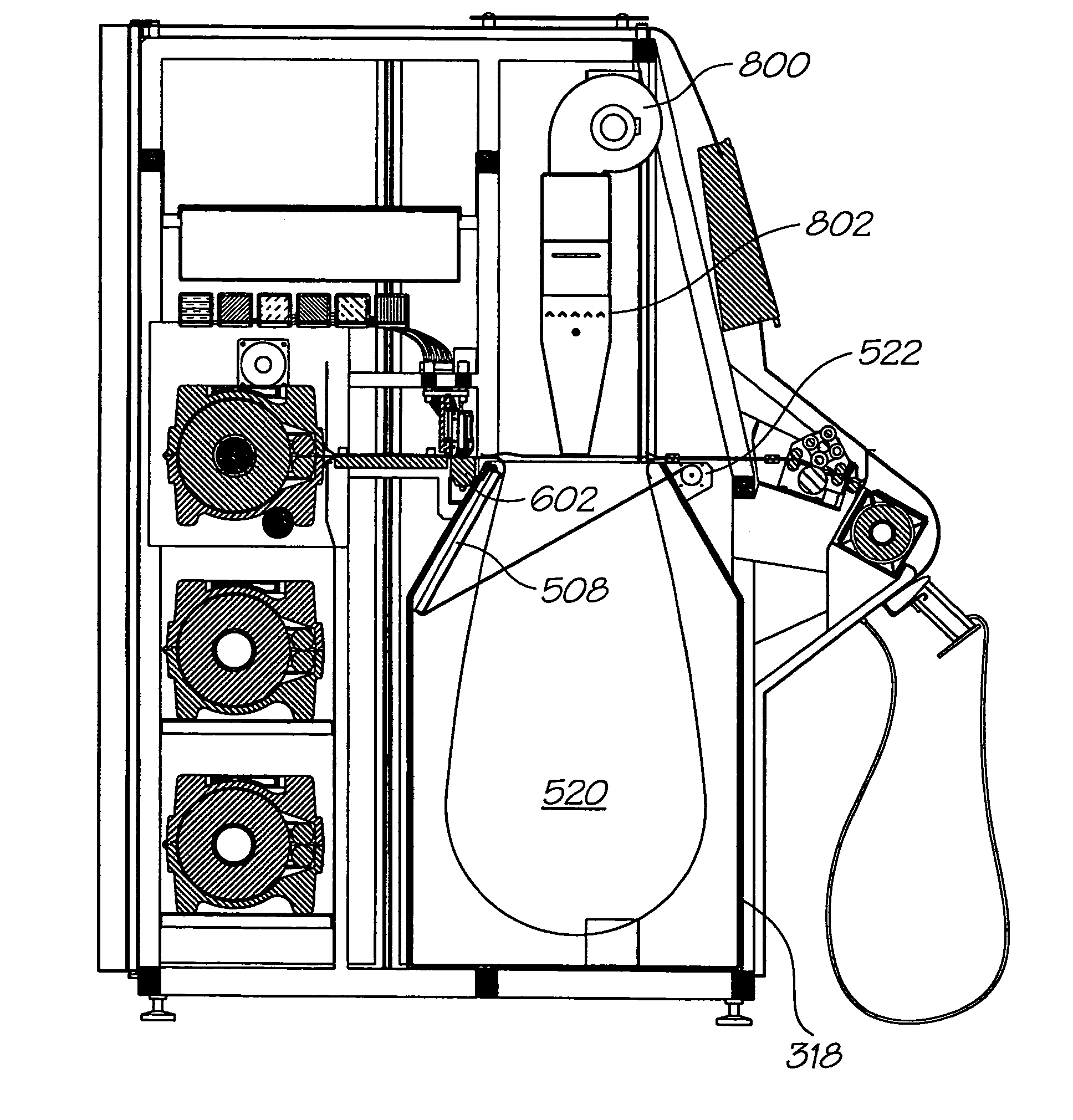

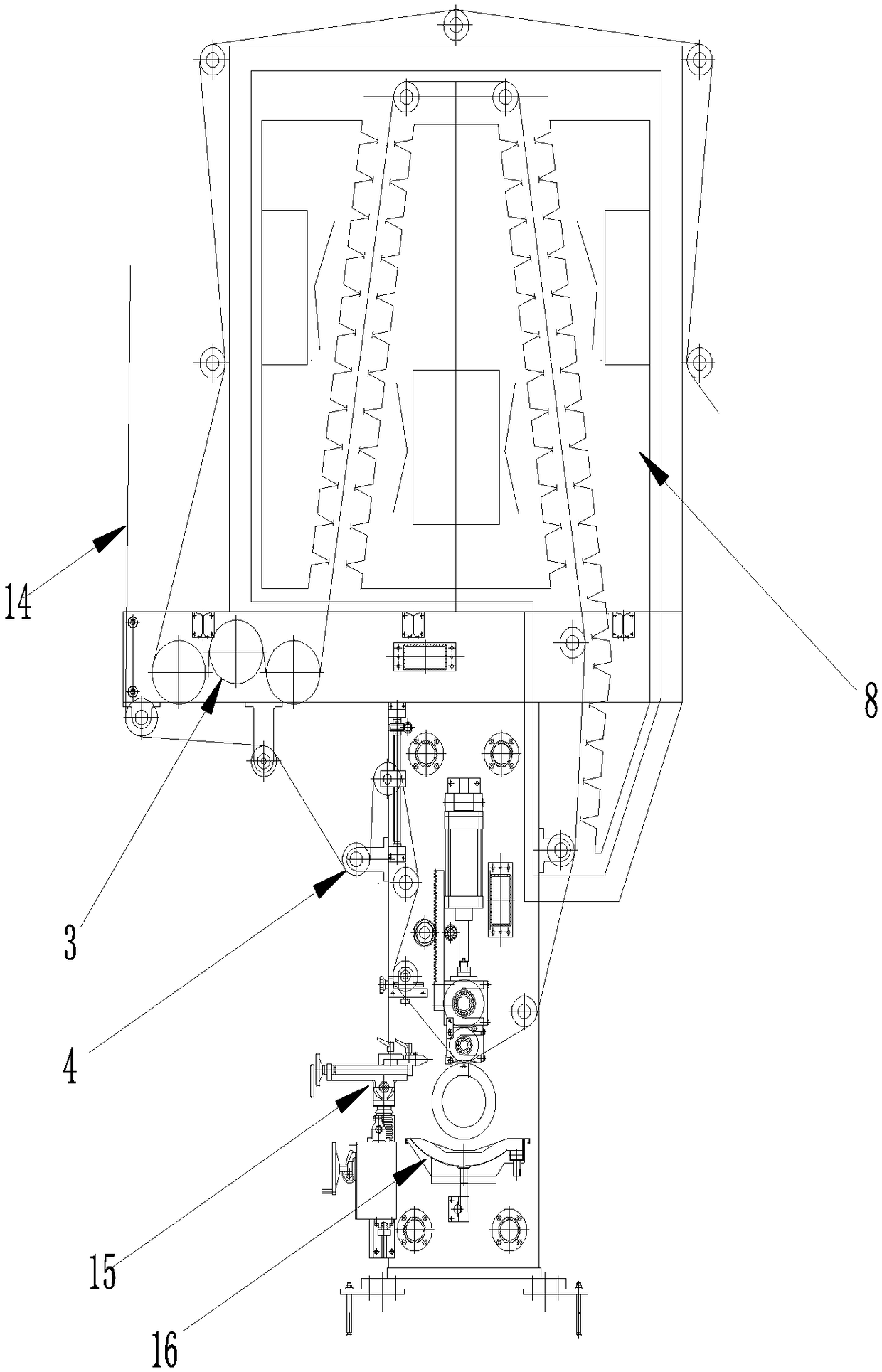

On-demand wallpaper printer having dryer

InactiveUS20050200682A1Eliminate stock-out, stock-control/ordering and stock obsolesces issuesEliminate inventoryInking apparatusDrying machines with progressive movementsWallpaper printerComputer printing

An on-demand wallpaper printer is provided comprising a pagewidth ink jet printhead for printing ink onto a media web moving along a path, a compartment arranged along the path downstream from the printhead so that the moving media web traverses the compartment and a source of heated air arranged above the compartment. The compartment has an opening configured so that the moving media web is able to descend into the compartment, as required, so as to adopt a suspended partial loop. The source of heated air is arranged above the opening and is operable to blow heated air through the opening into the compartment so as to dry printed ink on the suspended partial loop of the media web.

Owner:ZAMTEC +1

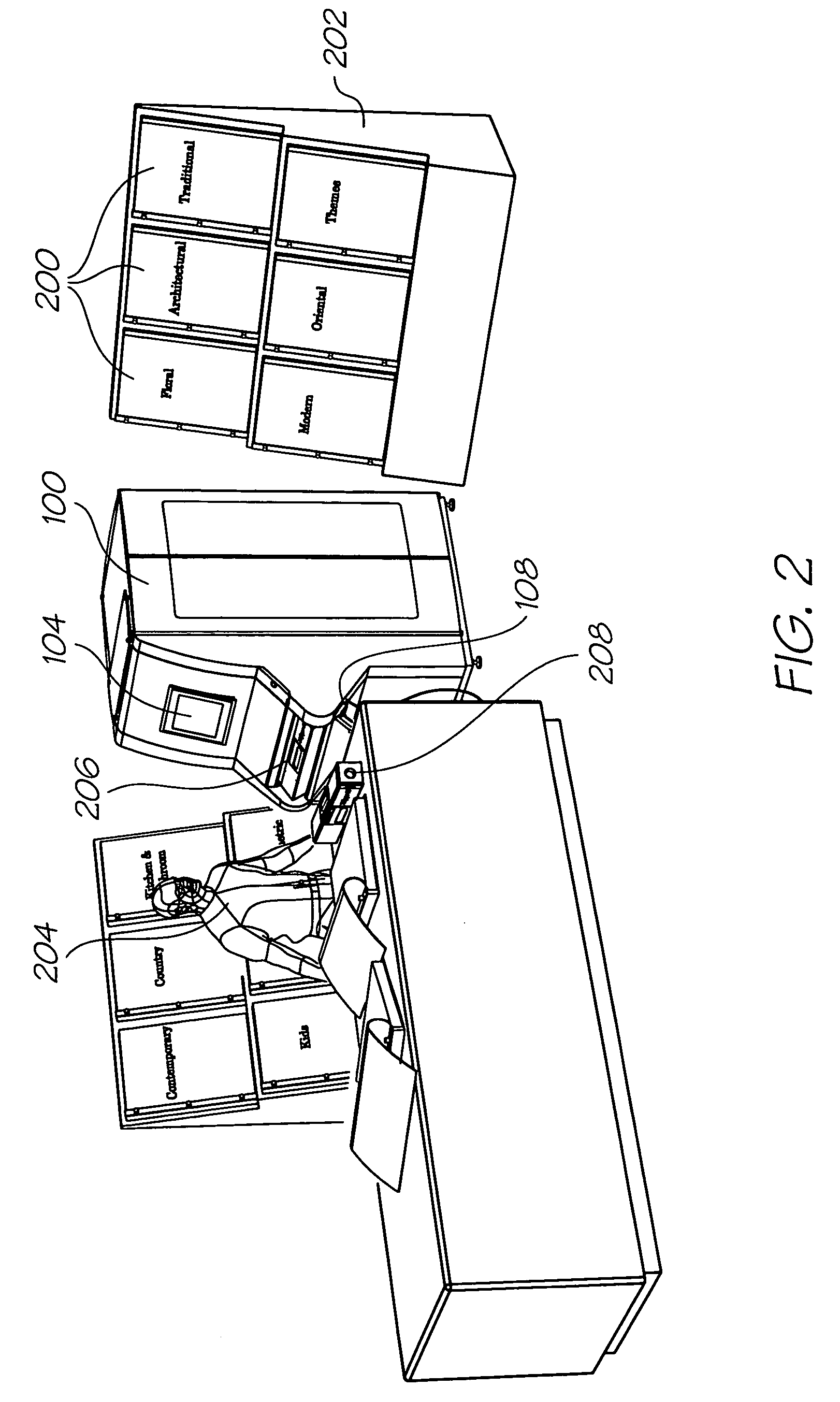

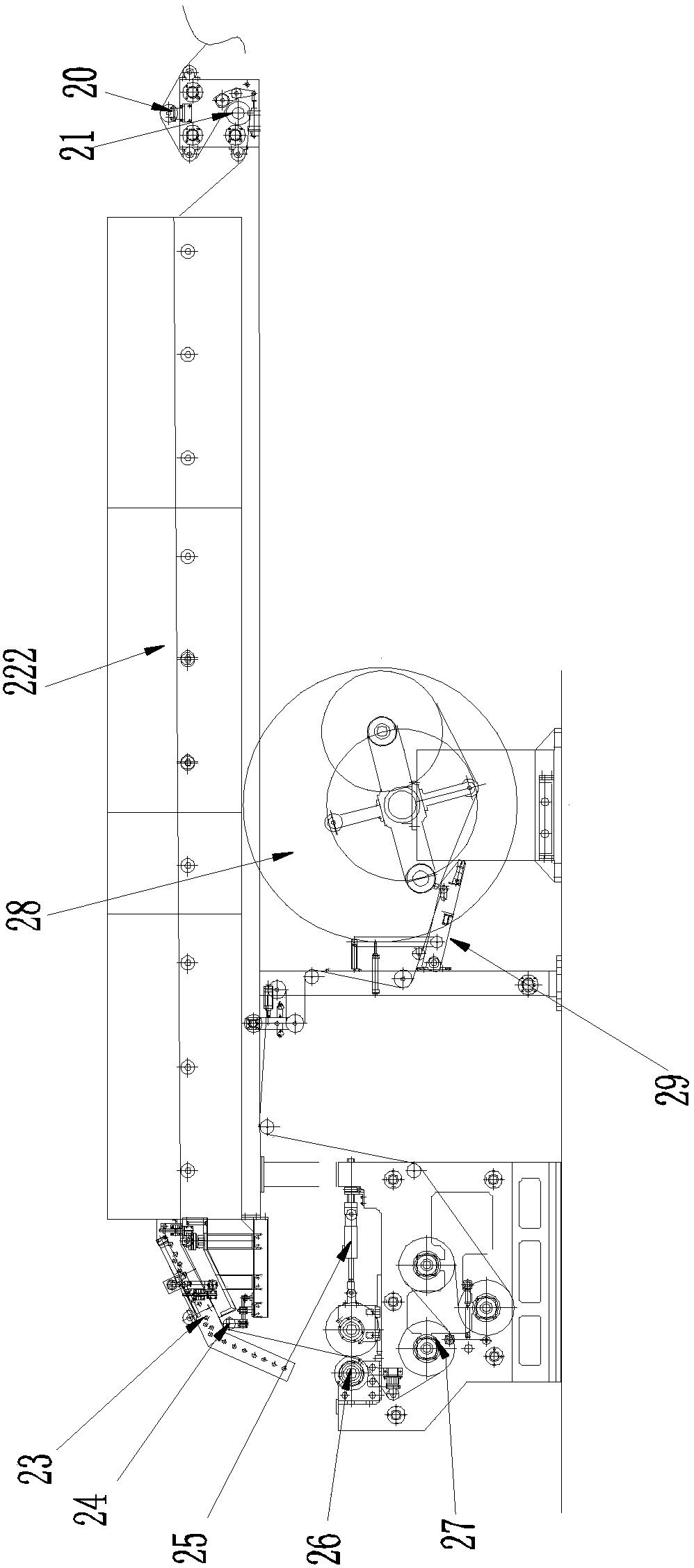

Mobile web printer

A mobile wallpaper printer for producing wallpaper, the printer comprising: a vehicle adapted to hold and transport the printer; input means for a consumer to select a wallpaper pattern to be printed on a media web to form the wallpaper; at least one media cartridge containing the media web; a printhead extending at least the width of the media web; drive means to drive the media web past the printhead; and, at least one processor to receive and process the selected wallpaper pattern and to control printing of the selected wallpaper pattern.

Owner:MEMJET TECH LTD

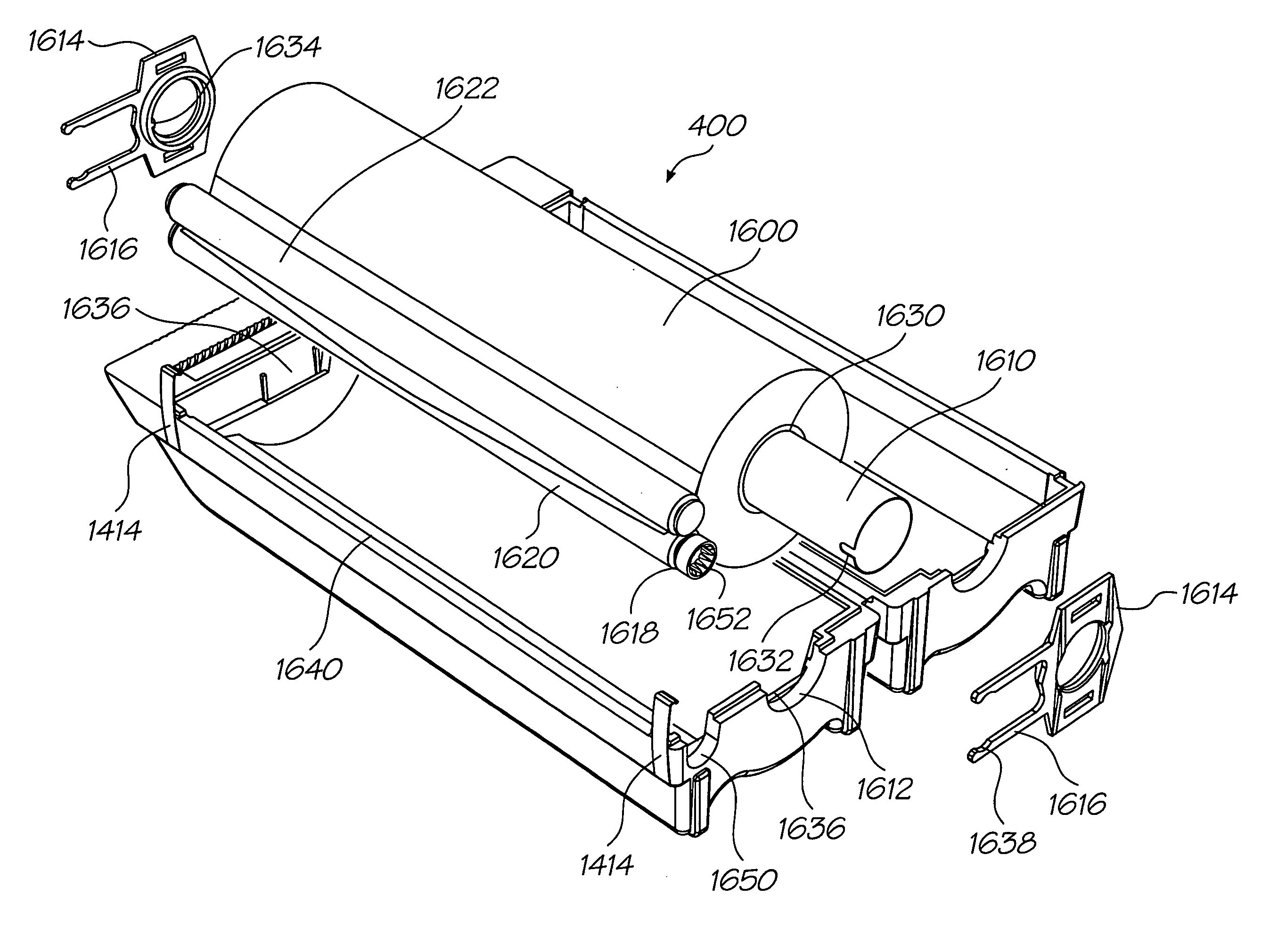

Combined cutter and slitter module for a printer

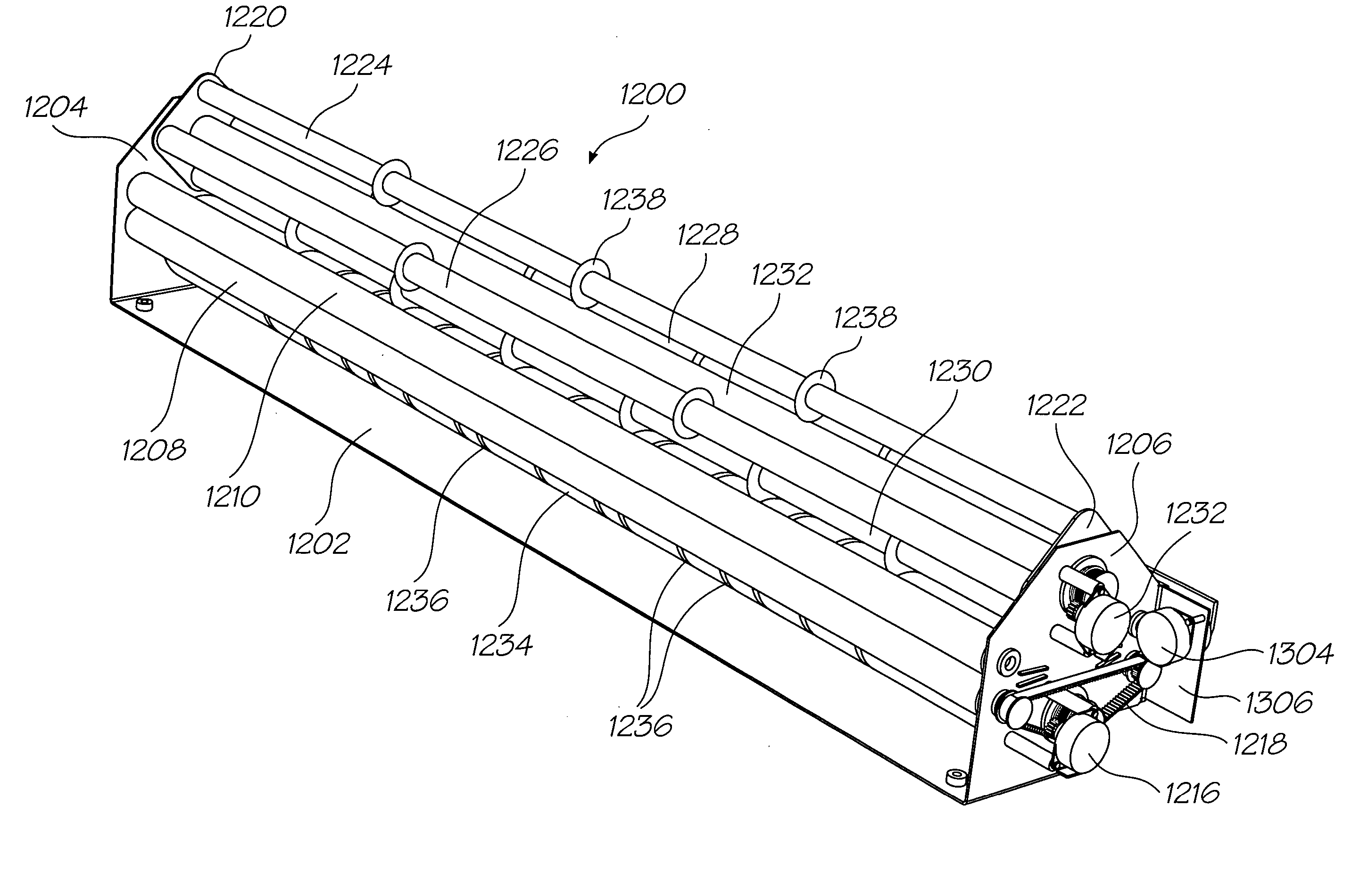

InactiveUS20050157141A1Reduce deliveryInking apparatusTypewritersWallpaper printerElectric machinery

A combined cutter and slitter module for a wallpaper printer, the combined cutter and slitter module comprising: at least two end plates, a media web able to pass between the at least two end plates; at least two slitter rollers rotatably held between the at least two end plates, each of the slitter rollers provided with at least one cutting disk, each of the cutting disks located at different positions along the length of the at least two slitter rollers; a guide roller positioned to selectively engage with at least one cutting disk, the media web able to be passed between the guide roller and the at least one cutting disk; a drive motor to rotate the guide roller; a first actuating motor to selectively rotate the at least two slitter rollers and thereby selectively engage at least one cutting disk with the guide roller; a transverse cutter positioned along at least the width of the media web; and, a second actuating motor to force the transverse cutter against the media web.

Owner:SILVERBROOK RES PTY LTD +1

Printhead assembly for a wallpaper printer

InactiveUS20040207688A1Eliminate stock-out, stock-control/ordering and stock obsolesces issuesEliminate inventoryTelevision system detailsInking apparatusWallpaper printerMechanical engineering

The invention provides a printhead assembly for a printer which prints onto a moving web that follows a path. A full width printhead located across the path of the printer. The printhead is a color printhead which is at least as wide as the web. The printhead is supplied with a number of different inks which are remote from the printhead and which are supplied to the printhead through tubes. In some embodiments the printhead is retained by a rail which is located across the path and along which the printhead slides into and out of a printing position.

Owner:ZAMTEC +1

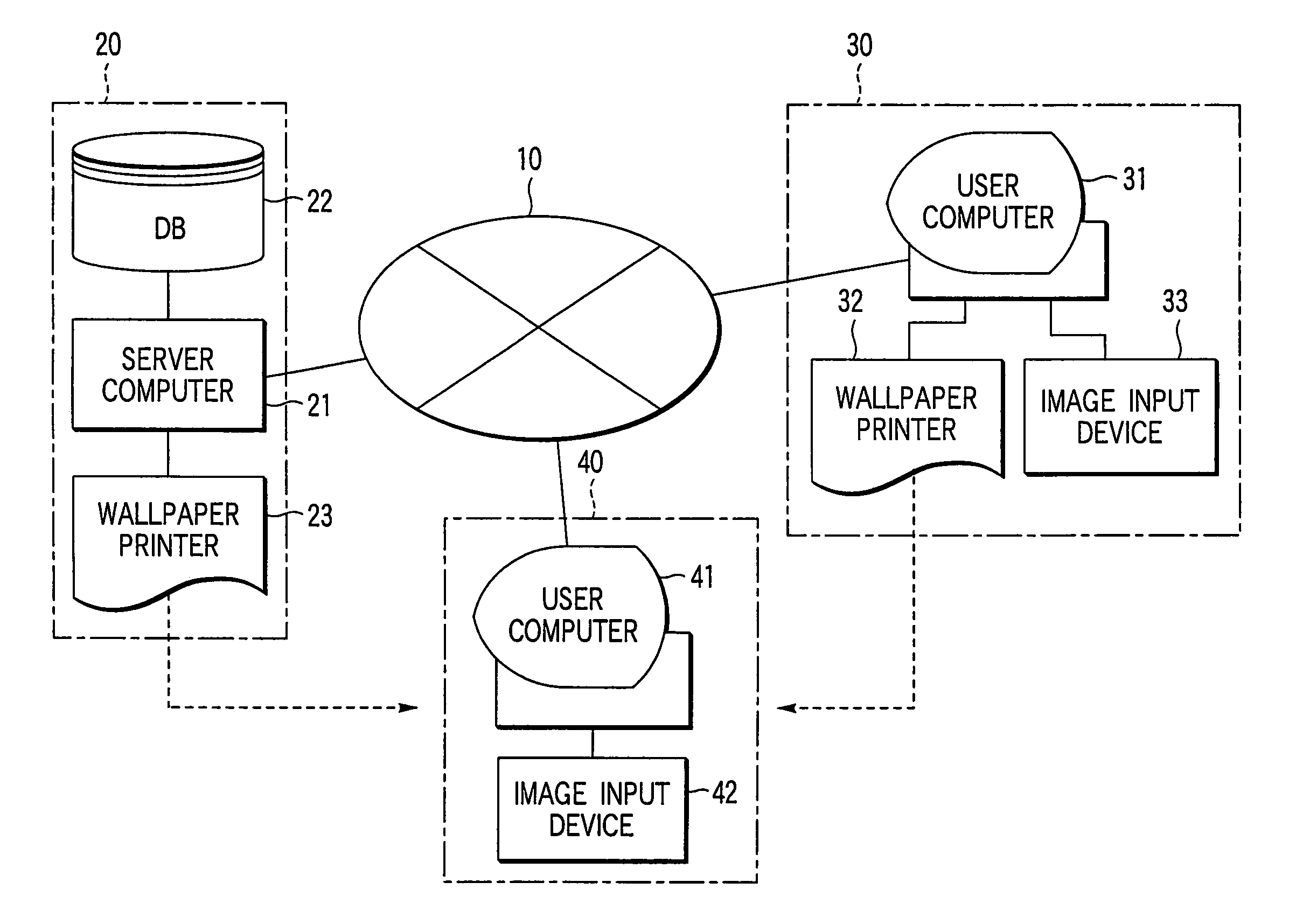

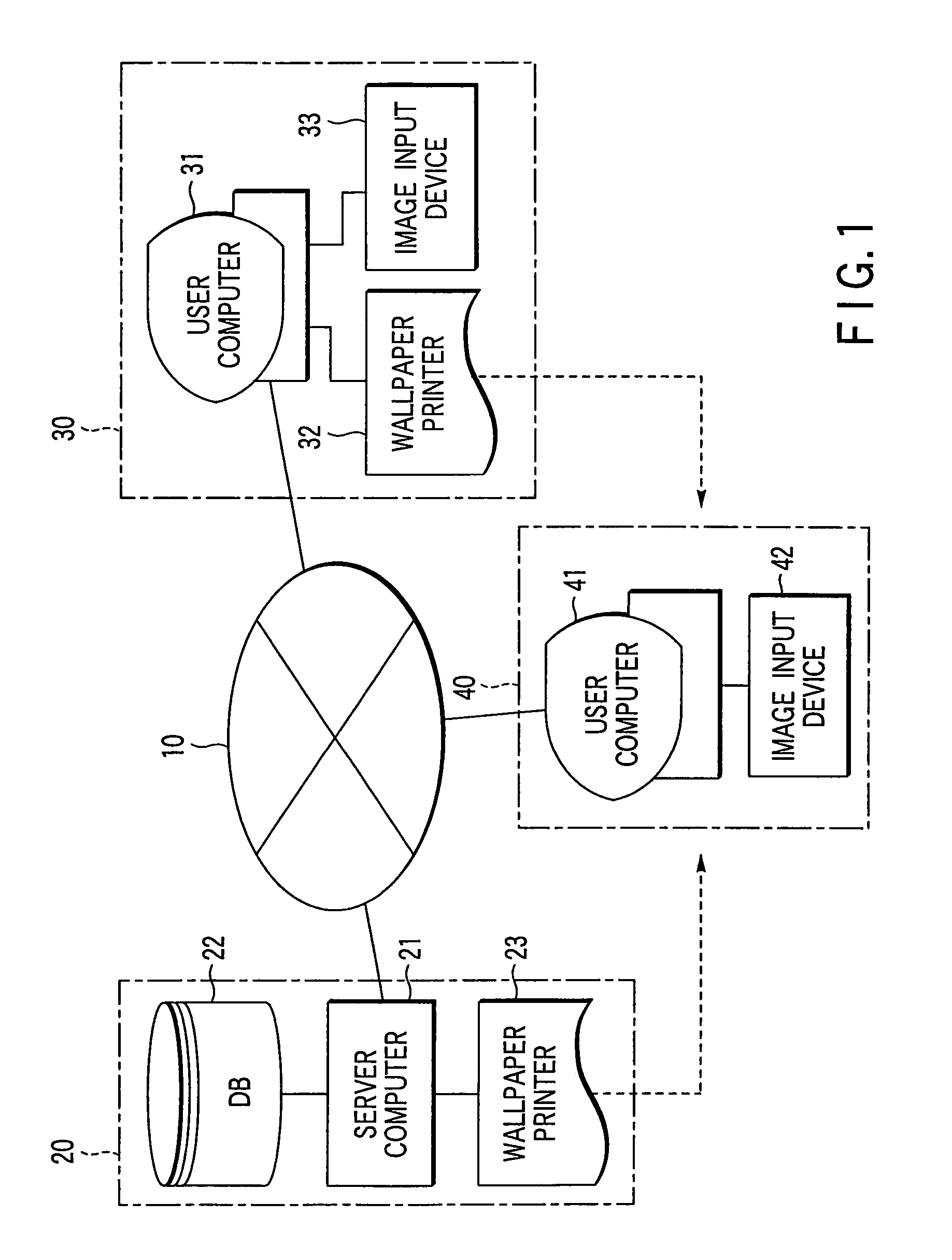

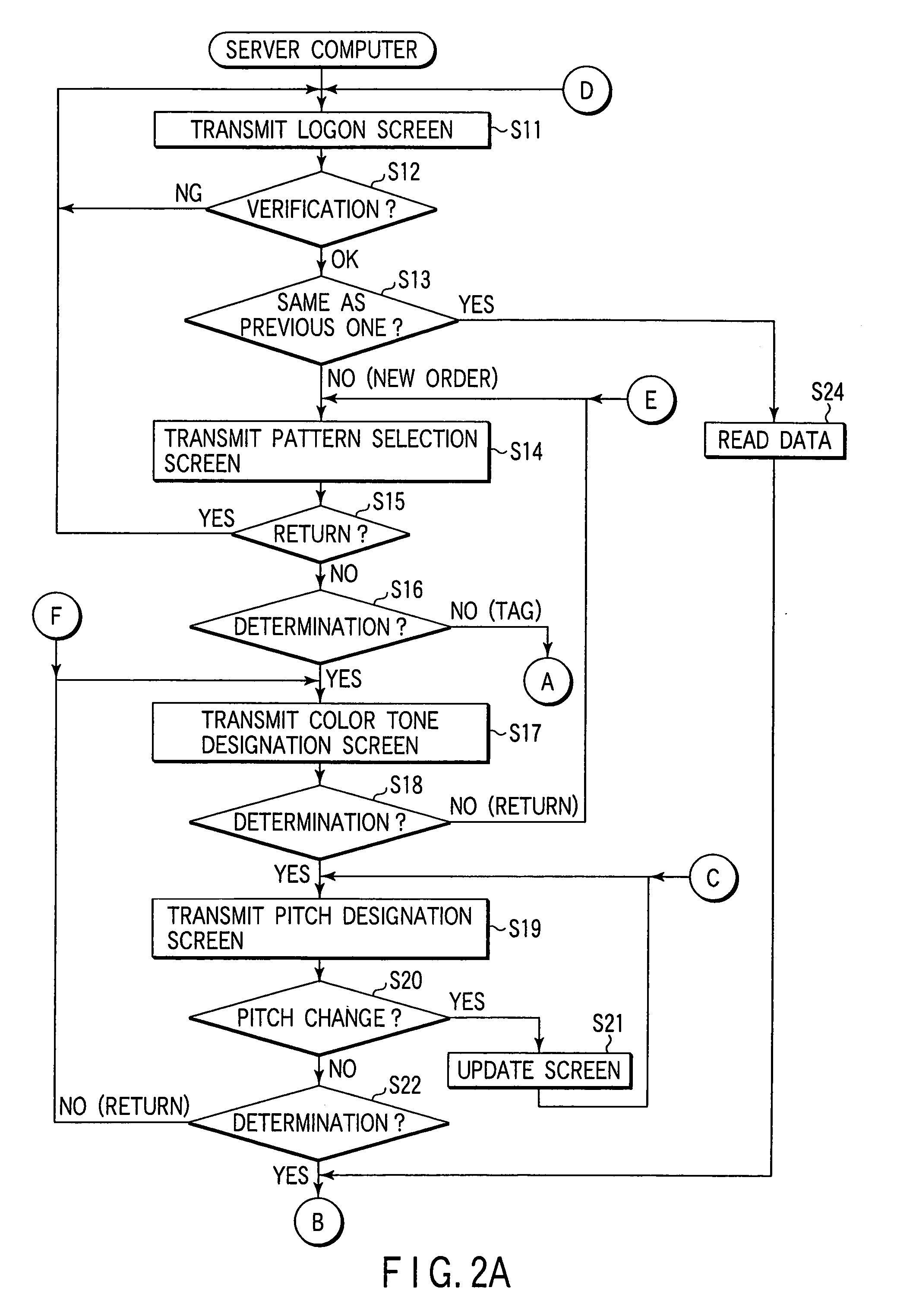

Wallpaper manufacturing method, wallpaper manufacturing apparatus, and program for causing computer to function as wallpaper manufacturing apparatus

InactiveUS6959646B2Easy to produceSuitable surfaceAddressographsPlaten pressesWallpaper printerThe Internet

An image of a design pattern of wallpaper stored in a data base (DB) is viewed by a user computer of a user who is a general consumer or a contractor from a server computer provided in a head office of a wallpaper manufacturer through the Internet. Further, upon accepting an order of wallpaper from the user who saw the image by the user computer, the server computer fetches the image of the design pattern from the DB. A wallpaper printer then prints the image on a wallpaper sheet, thereby manufacturing the wallpaper desired by the user. The produced wallpaper is delivered to the user who gave out the order by, for example, a door-to-door delivery service.

Owner:OLYMPUS CORP

Drying method for a printer

InactiveUS20050155248A1Avoid stickingAvoid enteringDrying using combination processesInking apparatusWallpaper printerComputer printing

The invention provides a method for drying a web of media in a printer such as a wallpaper printer. The method includes the step of loading the web in a path that traverses a compartment in a dryer in the printer. The compartment has an opening across the top. The web is allowed to descend into the compartment, as required, to lengthen the path.

Owner:SILVERBROOK RES PTY LTD +1

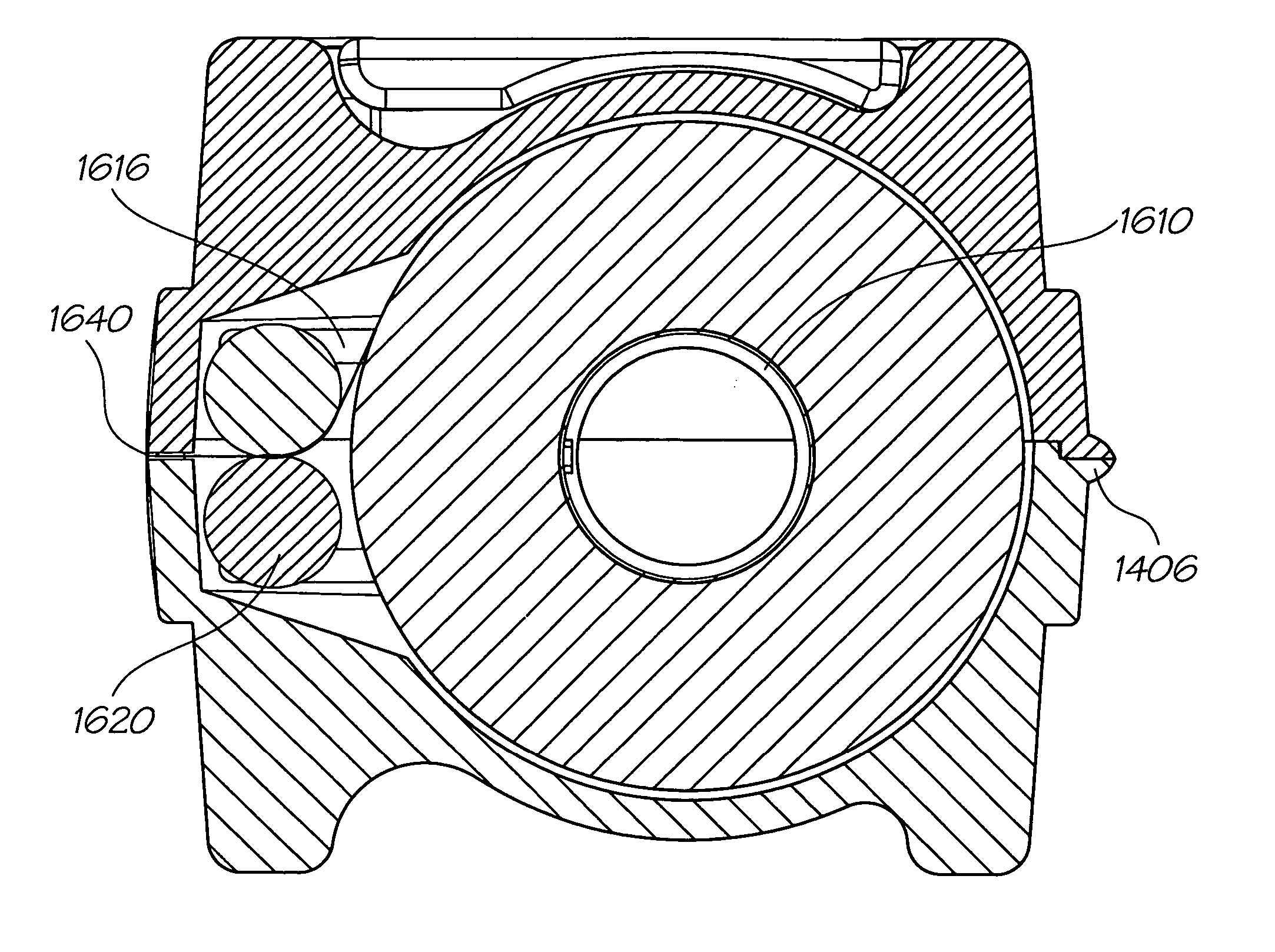

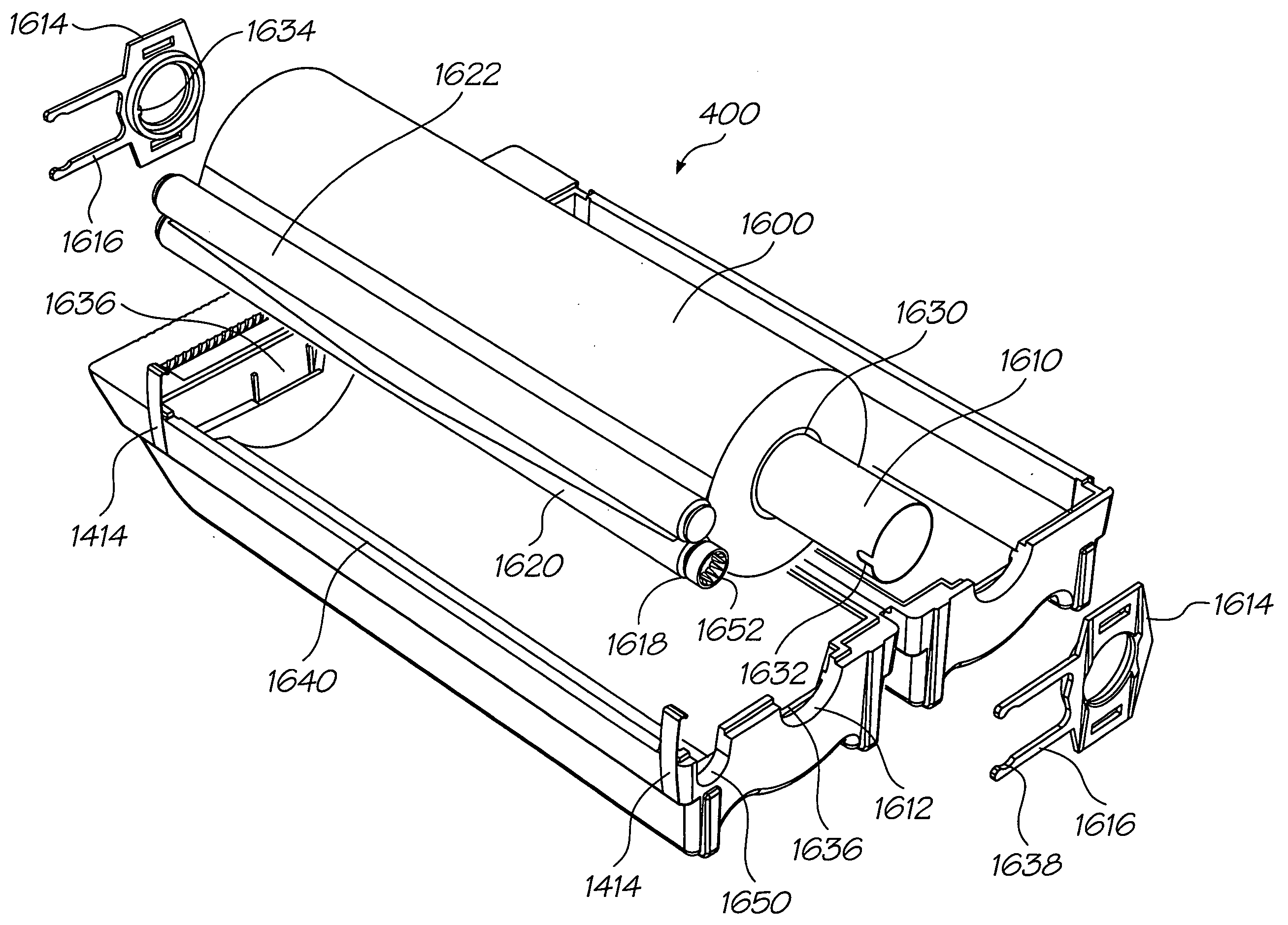

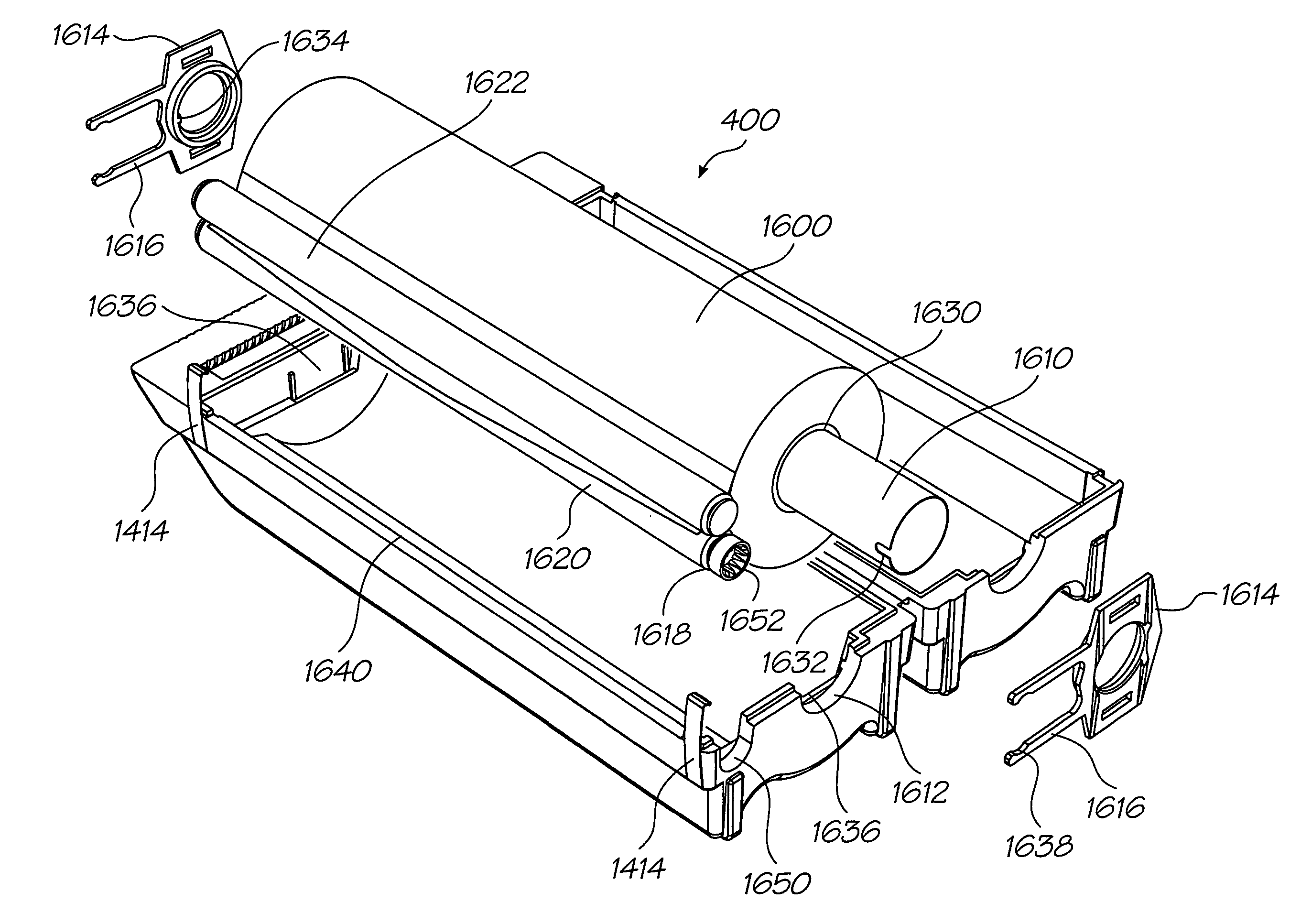

Media cartridge for wallpaper printer

InactiveUS7168654B2Eliminate stock-out, stock-control/ordering and stock obsolesces issuesEliminate inventoryContainers for annular articlesFilament handlingWallpaper printerElectric motor

A media cartridge is constructed as a case in which a roll of blank media may be deployed for supplying a wallpaper printer. The case has two halves, hinged together. An area between the two halves, when they are closed, defines a media supply slot. The case has internally and adjacent to the slot, a pair of rollers. At least one of the rollers is a driven roller which is supported at each end, by the case, for rotation by an external motor.

Owner:ZAMTEC +1

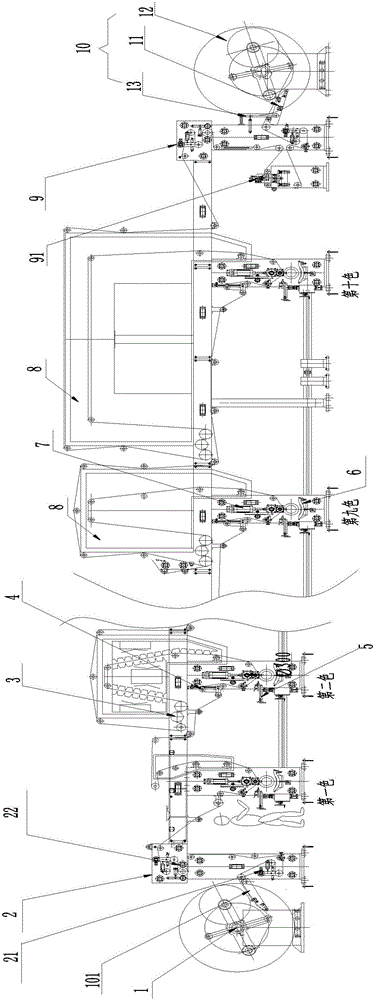

Coding type back printing automatic color register method

ActiveCN104772980AHigh precisionAvoid influencePrinting press partsWallpaper printerMotion controller

The invention discloses a coding type back printing automatic color register method. The method is implemented by a coding type back printing automatic color register device. The coding type back printing automatic color register device comprises a printing roller shaft, wherein the printing roller shaft is connected with a motor; the end of the printing roller shaft is connected with an encoder; a motion controller is connected with a coding machine; an automatic color register controller is further connected with a photoelectric head and the motion controller respectively; the coding machine and the photoelectric head are arranged on one straight line along the running direction of a material film. By using the coding type back printing automatic color register device, color codes are printed on the back sides of printed patterns, one color code is printed on the same phase once a printing roller rotates by a circle, and the printed color codes are completely consistent with front-side printed patterns, so that the problems of difficulty in detecting printed color codes during automatic color register of a wallpaper printer, high cost of flexible printing back printed color codes and complexity in operation in the prior art are solved by taking the printed color codes as reference color codes of color register.

Owner:XIAN AEROSPACE HUAYANG PRINTING & PACKAGING MACHINERY

In-line dryer for a printer

ActiveUS20050155252A1Avoid stickingAvoid enteringTypewritersDrying machines with progressive movementsWallpaper printerMechanical engineering

The invention provides a dryer for a printer such as a print on demand wallpaper printer. The dryer has a compartment with an opening across the top. The opening is in a path of a moving media web which is printed on by the printer. The opening is optionally covered by a door. A source of heated air is located above the opening and blows heated air downwardly onto the door, or the opening if the door is open. In general, the door covers the opening and acts to support the web when the door is closed. When the door is open, the moving web can enter the compartment.

Owner:SILVERBROOK RES PTY LTD +1

Printer incorporating a cutter module

InactiveUS20080018724A1Eliminate stock-out, stock-control/ordering and stock obsolesces issuesEliminate inventoryInking apparatusTypewritersPrint mediaComputer printing

A wallpaper printer is provided for printing wallpaper patterns on print media. The wallpaper printer includes a cabinet assembly. A plurality of ink reservoirs are mounted, in a releasable manner, within the cabinet assembly and store respective types of ink to be printed. A print media cartridge is mounted, in a releasable manner, within the cabinet assembly and carries a wound length of print media. A platen extends away from the print media cartridge to support print media provided from the print media cartridge. A stationary printhead is mounted within the cabinet assembly to extend transverse to the print media, and is configured to print a wallpaper pattern with the ink and upon print media provided from the platen. A cutter module is configured to transversely cut the printed print media so that the printed print media can be separated from the wound length.

Owner:MEMJET TECH LTD +1

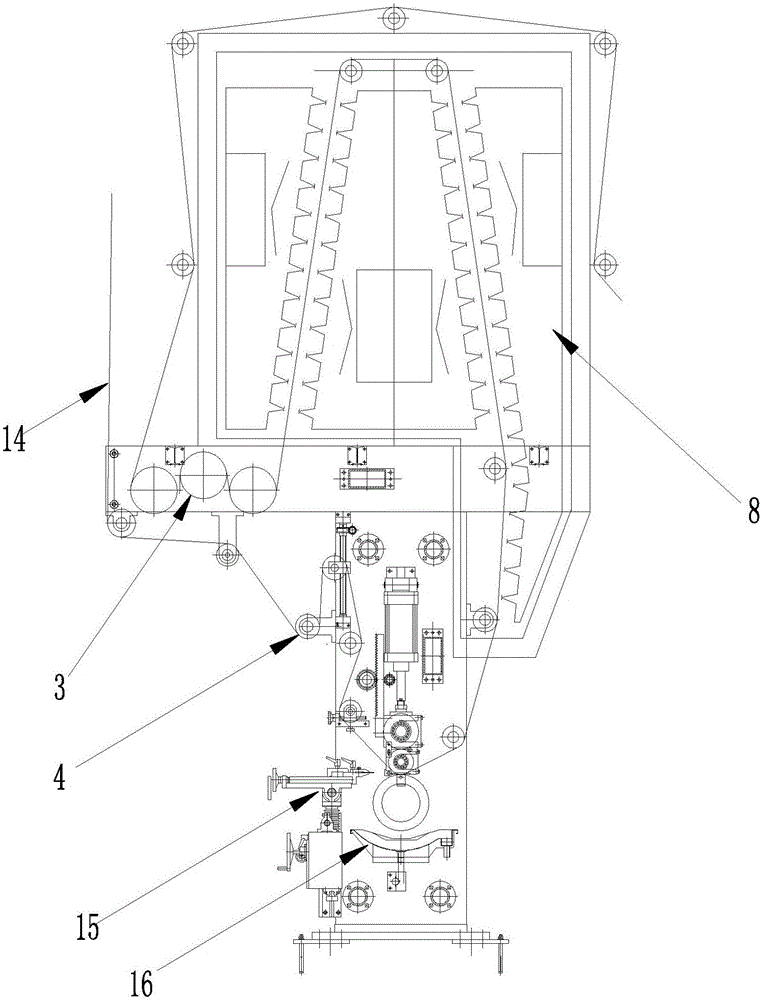

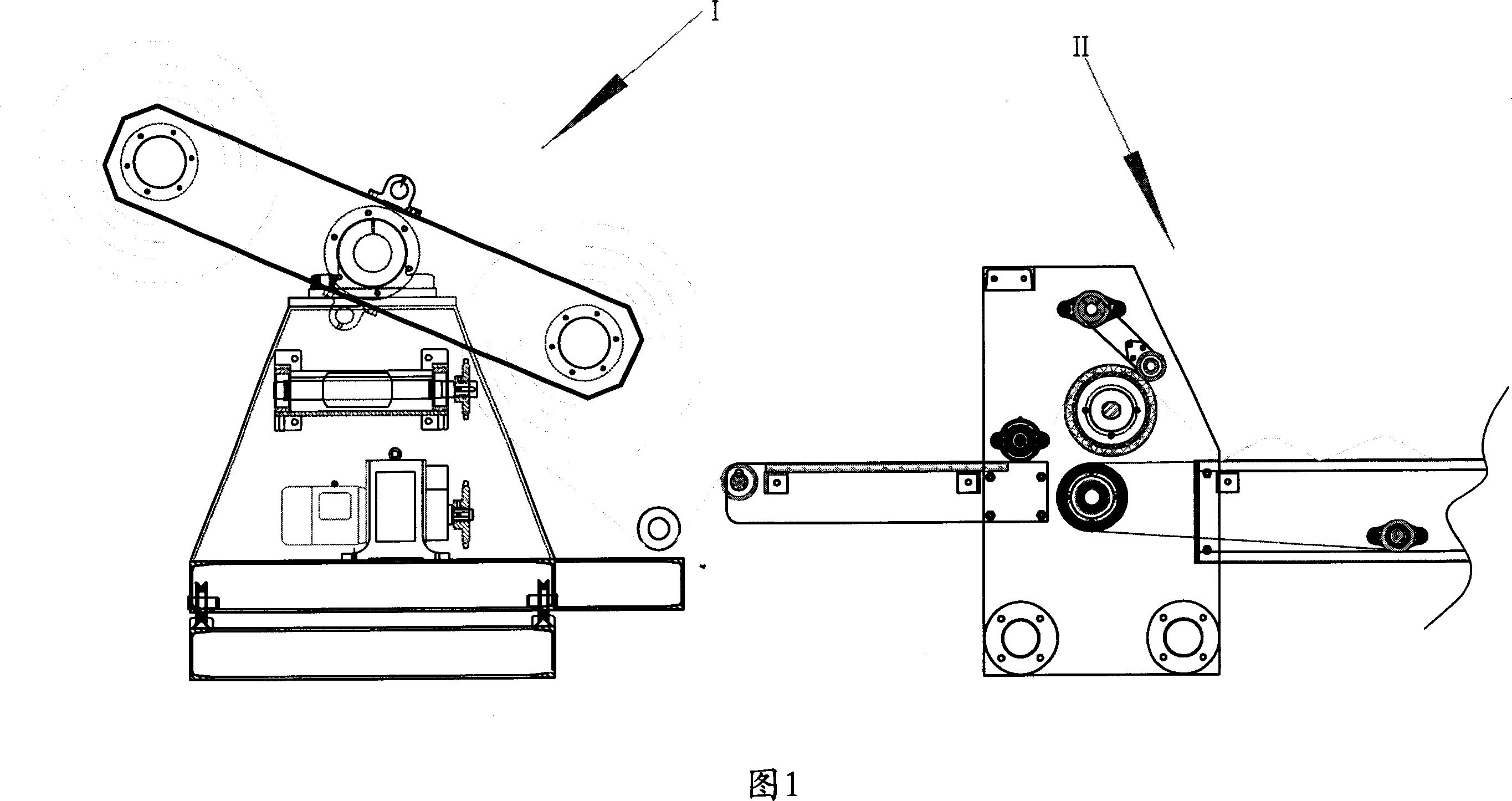

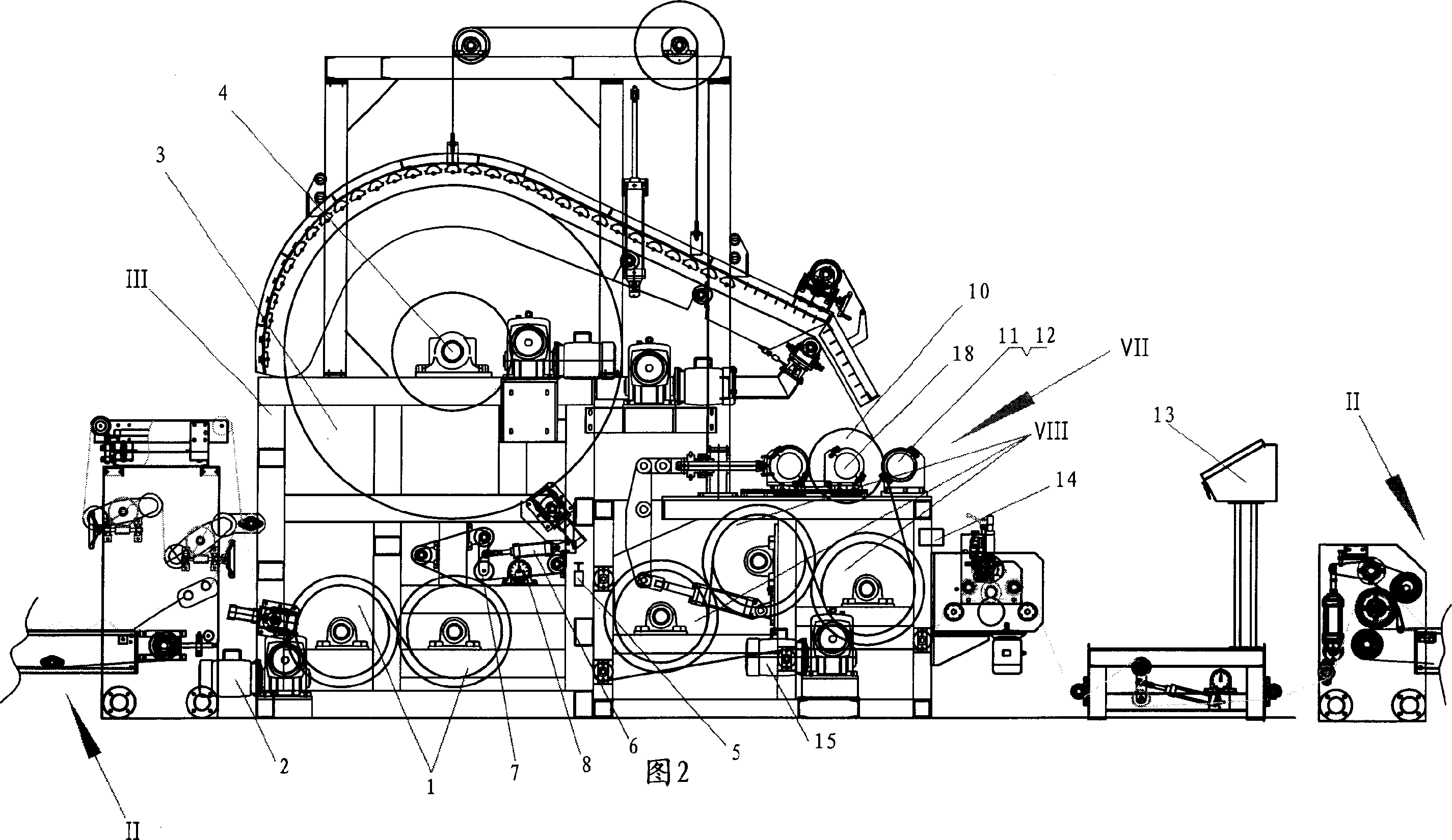

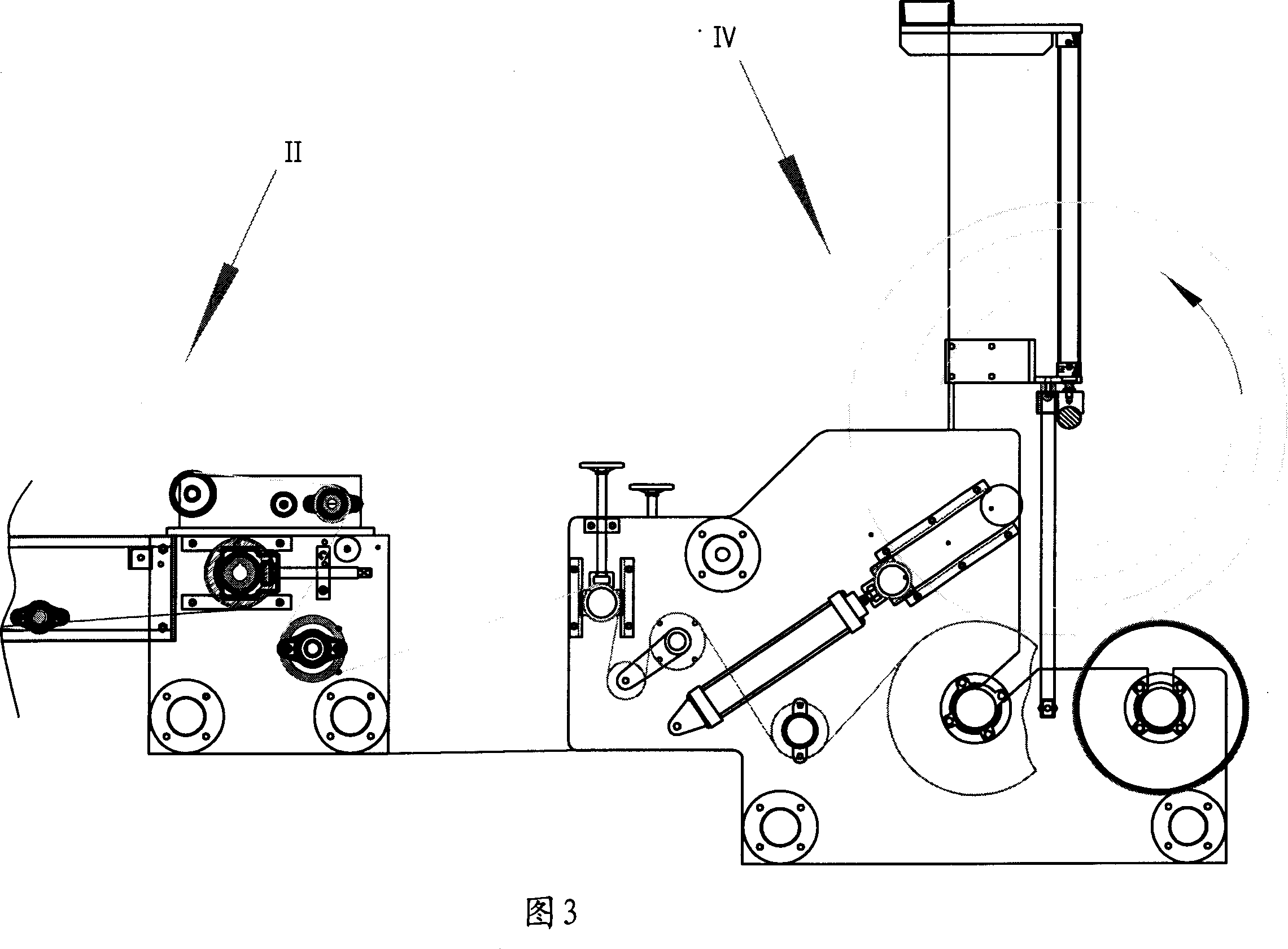

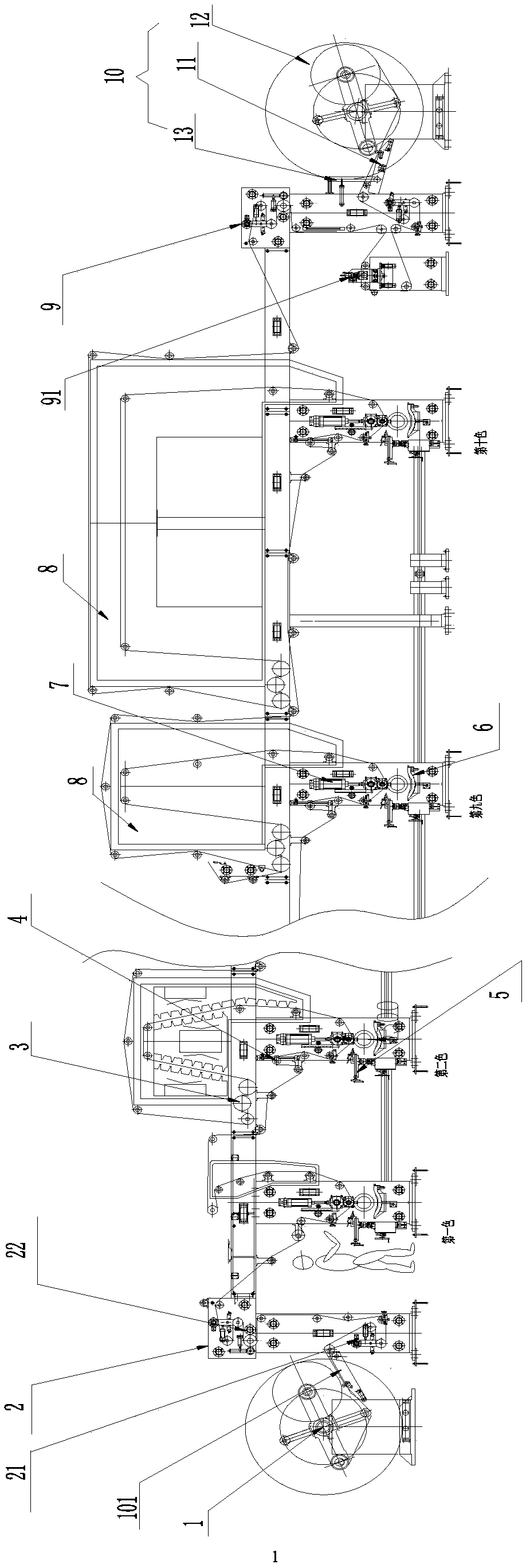

Whole-piece wallpaper printer

ActiveCN106335273AImprove the quality of decorationHigh precisionRotary pressesPrinting press partsWallpaper printerThrough transmission

The invention provides a whole-piece wallpaper printer. The whole-piece wallpaper printer comprises a reeling device, an unreeling device and at least one group of impression device located between the reeling device and the unreeling device; each group of impression device consists of a printing device and a dryer heating device; the groups of impression devices are connected through transmission guide rolls; the side of each printing device is provided with a scraper device and an ink supplying device; a material unreeling traction part is arranged between the impression device and the unreeling device; and a material reeling traction part is arranged between the impression device and the reeling device. The whole-piece wallpaper printer is characterized in that a cooling mechanism is additionally arranged on the dryer heating device; and a pattern alignment compensation mechanism is connected to the rear part of the cooling mechanism. The whole-piece wallpaper printer has the beneficial effects that the application width of each device is changed, and multiple detection mechanisms and adjustment mechanisms are arranged, so that real-time detection and real-time adjustment are realized, and therefore whole-piece wallpaper applicable to a whole wall surface can be manufactured; decoration quality is greatly improved; the quality of the wallpaper product is far better than that of current narrow-width wallpaper; precision of a manufacture process is high; printing quality is good; and machining efficiency is high.

Owner:ZHEJIANG MEIGE MACHINERY

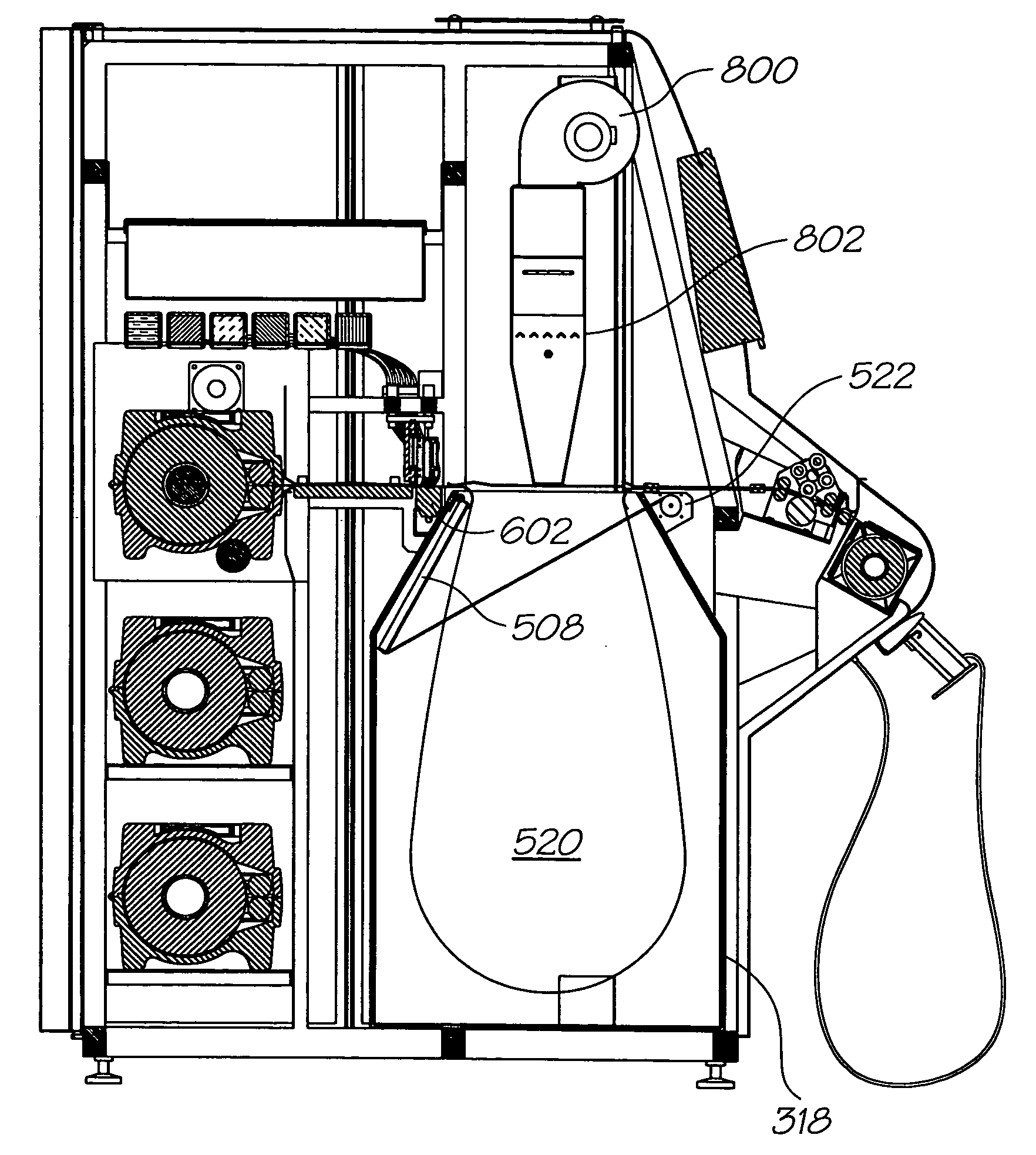

Web Printer Incorporating a Drying Module

InactiveUS20070227382A1Reduce deliveryEnable or facilitate significant reductions in customer wallpaper wastageInking apparatusTypewritersWallpaper printerForced-air

A wallpaper printer includes a support frame. A cabinet assembly is mounted on the support frame. A drying module is operatively mountable with respect to the support frame and defines a first chamber and a second drying chamber. A heating element is positioned within the first chamber. At least one fan is operatively positioned with respect to the first chamber to force air past the heating element. The first chamber is configured to direct the heated air through an opening into a second drying chamber. The drying module includes a motorized door for opening and closing the opening. The drying module is configured so that, in use, the second drying chamber receives printed media via the opening. The drying module further includes at least one circulation duct to transfer at least a portion of the heated air from the second drying chamber towards the at least one fan.

Owner:ZAMTEC +1

Media cartridge for wallpaper printer

InactiveUS20050158105A1Avoid stickingAvoid enteringContainers for annular articlesFilament handlingWallpaper printerEngineering

A media cartridge is constructed as a case in which a roll of blank media may be deployed for supplying a wallpaper printer. The case has two halves, hinged together. An area between the two halves, when they are closed, defines a media supply slot. The case has internally and adjacent to the slot, a pair of rollers. At least one of the rollers is a driven roller which is supported at each end, by the case, for rotation by an external motor.

Owner:ZAMTEC +1

Wallpaper embosser

InactiveCN1966257AAdjustable volumeReduce wearMechanical working/deformationWallpaper printerElectric machinery

The invention relates to a wallpaper printer, which comprises wallpaper releaser, transmitter, frame and wallpaper coiler, wherein two sides of frame via transmitters are connected to the wallpaper releaser and wallpaper coiler; the frame is mounted with heater, tension adjuster, cutter printer and cooling wheel; the heater, printer and cooling wheel are connected to their driving servo motors; via synchronous transmissions, the position of cutter printer can be corrected. The invention can avoid mechanical transmitting system and differential correcting system, with high accuracy and low noise.

Owner:谭日和

Wallpaper printer with removable printhead

InactiveUS20050156956A1Avoid stickingAvoid enteringTypewritersOther printing apparatusWallpaper printerCoupling

A printer for producing rolls of wallpaper has a housing in which is located a media path which extends from a blank media intake to a wallpaper exit slot. A multi-color roll width printhead located in the housing and across the media path. The printhead is supplied by separate ink reservoirs and the reservoirs are connected to the printhead by an ink supply harness. A disconnect coupling is placed between the reservoirs and the printhead. Inputs to the printer include one or more input devices for capturing operator instructions. A processor accepts the operator inputs and configures the printer for producing a particular roll.

Owner:SILVERBROOK RES PTY LTD

Self threading wallpaper printer

InactiveUS7249838B2Eliminate stock-out, stock-control/ordering and stock obsolesces issuesEliminate inventoryTypewritersOther printing apparatusPrint mediaWallpaper printer

A self threading printer is disclosed for producing rolls of wallpaper. It features a media loading area adapted to support a media cartridge in a position so that a media supply slot of the cartridge is closely adjacent to a pilot guide. The device's cabinet contains a media path which extends from the pilot guide to a printed media dispensing slot. A printhead is located across the media path and an internal processor accepts operator inputs which are used to configure the printer for producing a particular roll. A motor within the cabinet advances a media web out of the media cartridge and one or more other motors urge the media along the path and out of the dispensing slot.

Owner:MEMJET TECH LTD +1

Consumer tote for wallpaper printer

InactiveUS20050157151A1Avoid stickingAvoid enteringContainers for annular articlesFilament handlingWallpaper printerEngineering

A consumer tote for a roll of wallpaper is disclosed. The tote has a disposable exterior with a main access flap and a pair of core access openings, one at each end. The tote has an interior in which may be located a disposable core. The core aligns with the access openings. In some embodiments there is a gap between the access flap and an adjacent edge of the exterior, when the flap is closed. In preferred embodiments, the core is supported at each end by a molding having a hub which engages the core.

Owner:MEMJET TECH LTD +1

Self threading wallpaper printer

InactiveUS20050157150A1Eliminate stock-out, stock-control/ordering and stock obsolesces issuesEliminate inventoryTypewritersOther printing apparatusPrint mediaWallpaper printer

A self threading printer is disclosed for producing rolls of wallpaper. It features a media loading area adapted to support a media cartridge in a position so that a media supply slot of the cartridge is closely adjacent to a pilot guide. The device's cabinet contains a media path which extends from the pilot guide to a printed media dispensing slot. A printhead is located across the media path and an internal processor accepts operator inputs which are used to configure the printer for producing a particular roll. A motor within the cabinet advances a media web out of the media cartridge and one or more other motors urge the media along the path and out of the dispensing slot.

Owner:MEMJET TECH LTD +1

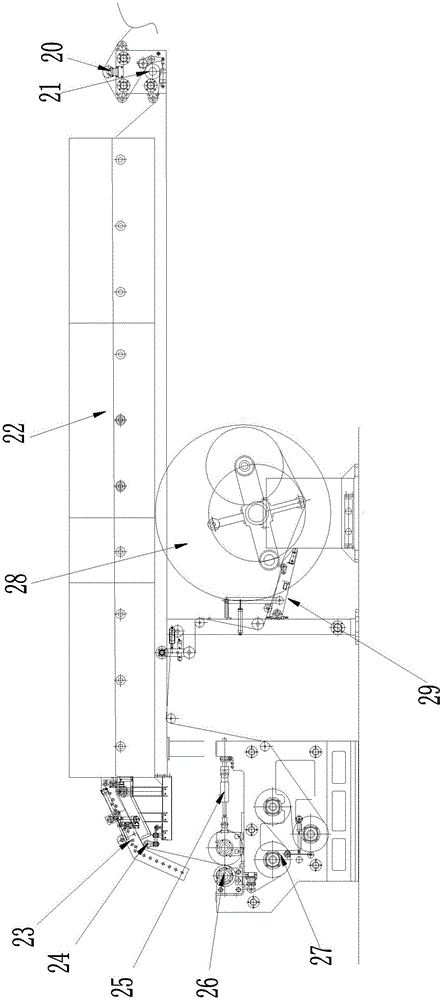

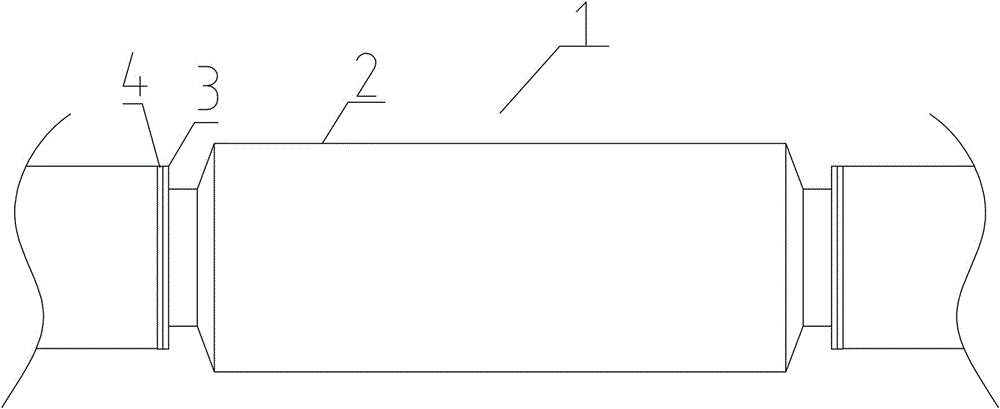

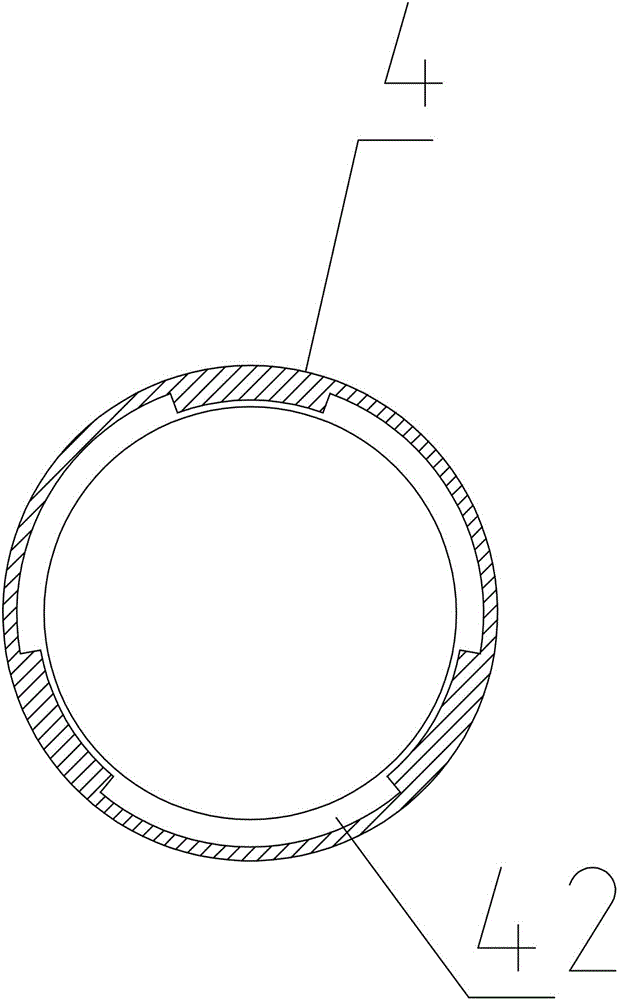

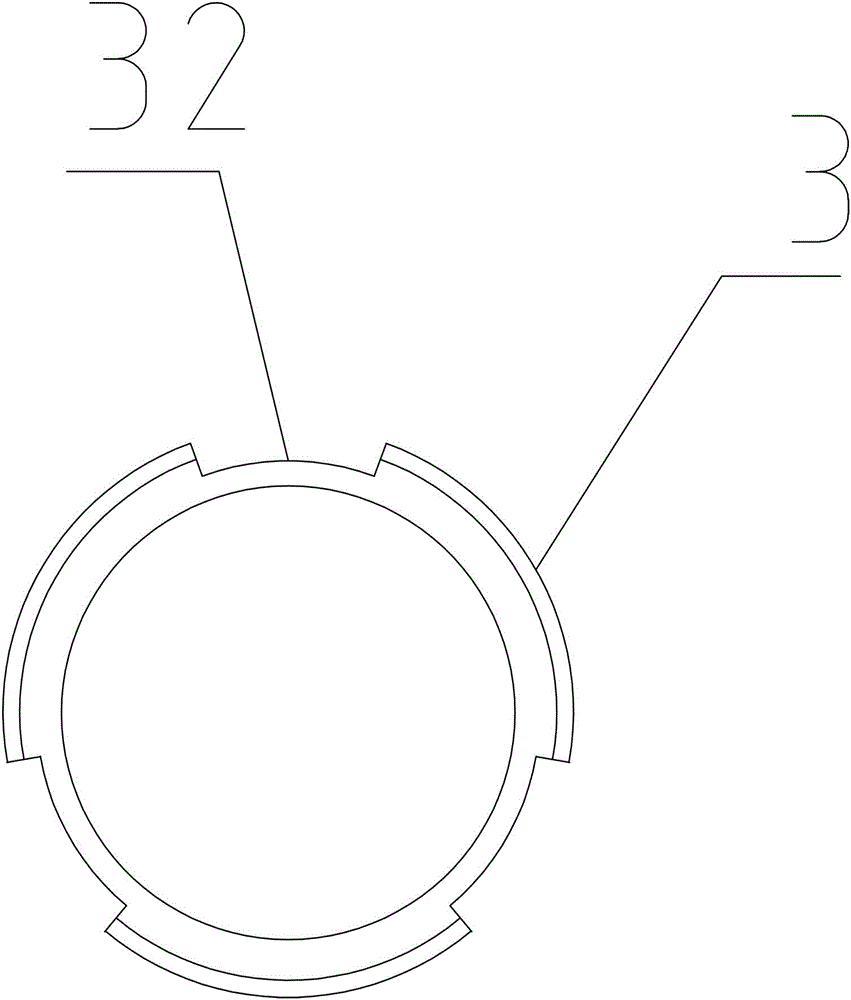

Round screen printing plate machine of round concave wallpaper printer

InactiveCN104417020AEliminate the effect of precisionReasonable designScreen printersScreen printingDrive shaft

Disclosed is a round screen printing plate machine of a round concave wallpaper printer. The round screen printing plate machine of the round concave wallpaper printer comprises a round screen drive device, a round screen printing plate and a connection device connected with the round screen drive device and the round screen printing plate, wherein the round screen printing plate comprises a round screen printing plate roller, and round screen printing plate seats which are respectively arranged at two ends of the round screen printing plate roller, the round screen printing plate seats are in circular ring shape, one face of each round screen printing plate seat is connected with one end of the round screen printing plate roller, a plurality of bulges which are evenly distributed are arranged on the other face of each round screen printing plate seat, the connection device comprises a plate seat clamp ring and a tight locking device, the plate seat clamp ring is in annulus shape, one face of the plate seat clamp ring is connected with a drive shaft of the round screen drive device, a plurality of grooves which are evenly distributed are formed in the annulus inner wall of the plate seat clamp ring, the bulges and the grooves are superposed, and the tight locking device fixes the plate seat clamp ring and the round screen printing plate seats. The round screen printing plate machine of the round concave wallpaper printer has the advantages that the tight locking device fixes the plate seat clamp ring and the round screen printing plate seats, the plate seat clamp ring and the round screen printing plate seats synchronously run, and influences on printing accuracy of wallpaper, caused by mechanical tolerance and intervals among the plate seat clamp ring and the round screen printing plate seats, are eliminated.

Owner:湖北浩博特装饰材料有限公司

Mobile web printer

InactiveUS20050156959A1Reduce deliveryTypewritersOther printing apparatusWallpaper printerEngineering

A mobile wallpaper printer for producing wallpaper, the printer comprising: a vehicle adapted to hold and transport the printer; input means for a consumer to select a wallpaper pattern to be printed on a media web to form the wallpaper; at least one media cartridge containing the media web; a printhead extending at least the width of the media web; drive means to drive the media web past the printhead; and, at least one processor to receive and process the selected wallpaper pattern and to control printing of the selected wallpaper pattern.

Owner:MEMJET TECH LTD

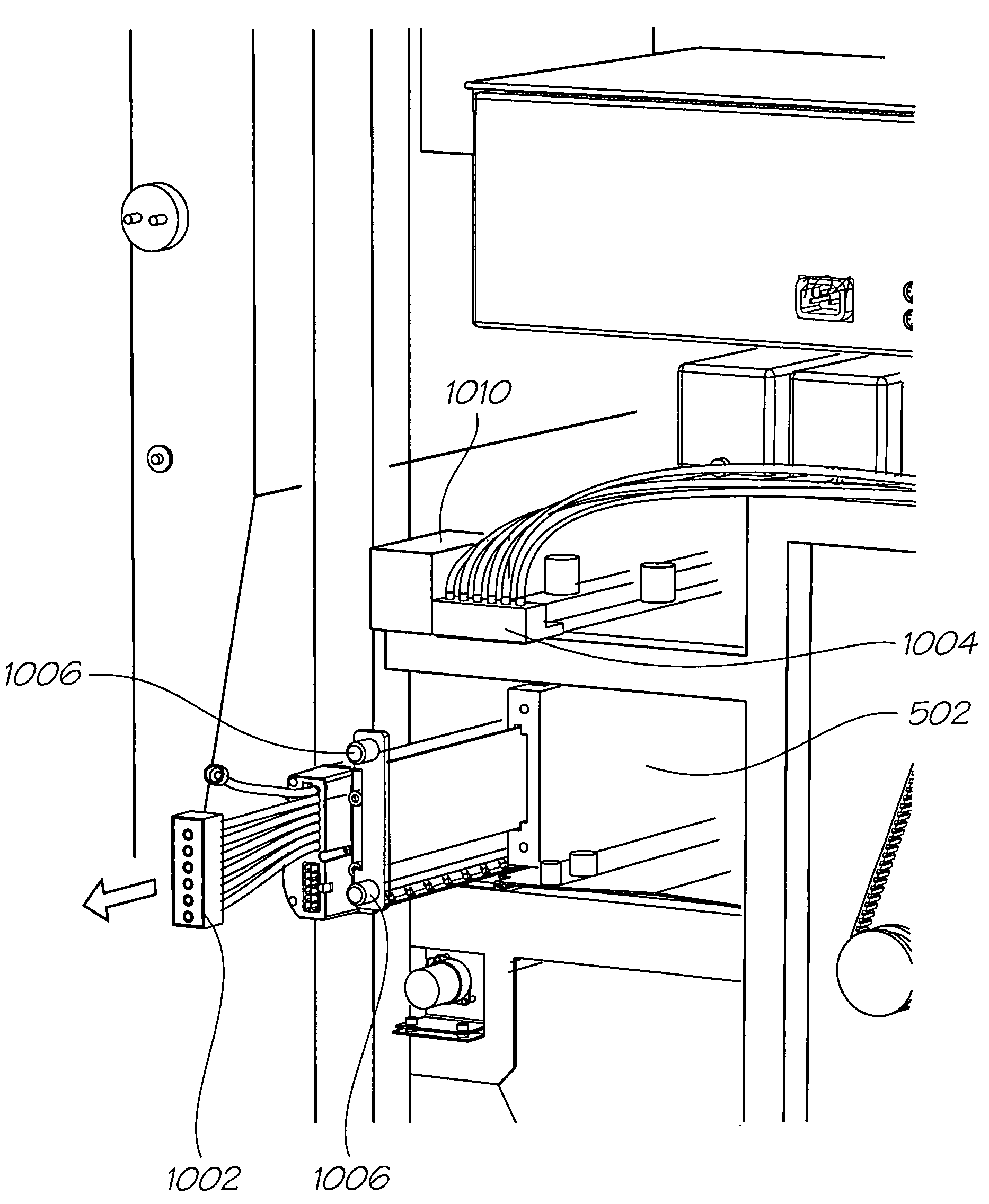

Removable printhead assembly for a wallpaper printer

ActiveUS7287828B2Eliminate stock-out, stock-control/ordering and stock obsolesces issuesEliminate inventoryOther printing apparatusWallpaper printerEngineering

The invention provides a printhead assembly for a printer which prints onto a moving web that follows a path. A full width printhead located across the path of the printer. The printhead is a color printhead which is at least as wide as the web. The printhead is supplied with a number of different inks which are remote from the printhead and which are supplied to the printhead through tubes. In some embodiments the printhead is retained by a rail which is located across the path and along which the printhead slides into and out of a printing position.

Owner:MEMJET TECH LTD +1

Printhead assembly for a wallpaper printer

InactiveUS7607756B2Eliminate stock-out, stock-control/ordering and stock obsolesces issuesEliminate inventoryTelevision system detailsInking apparatusWallpaper printerEngineering

The invention provides a printhead assembly for a printer which prints onto a moving web that follows a path. A full width printhead located across the path of the printer. The printhead is a color printhead which is at least as wide as the web. The printhead is supplied with a number of different inks which are remote from the printhead and which are supplied to the printhead through tubes. In some embodiments the printhead is retained by a rail which is located across the path and along which the printhead slides into and out of a printing position.

Owner:ZAMTEC +1

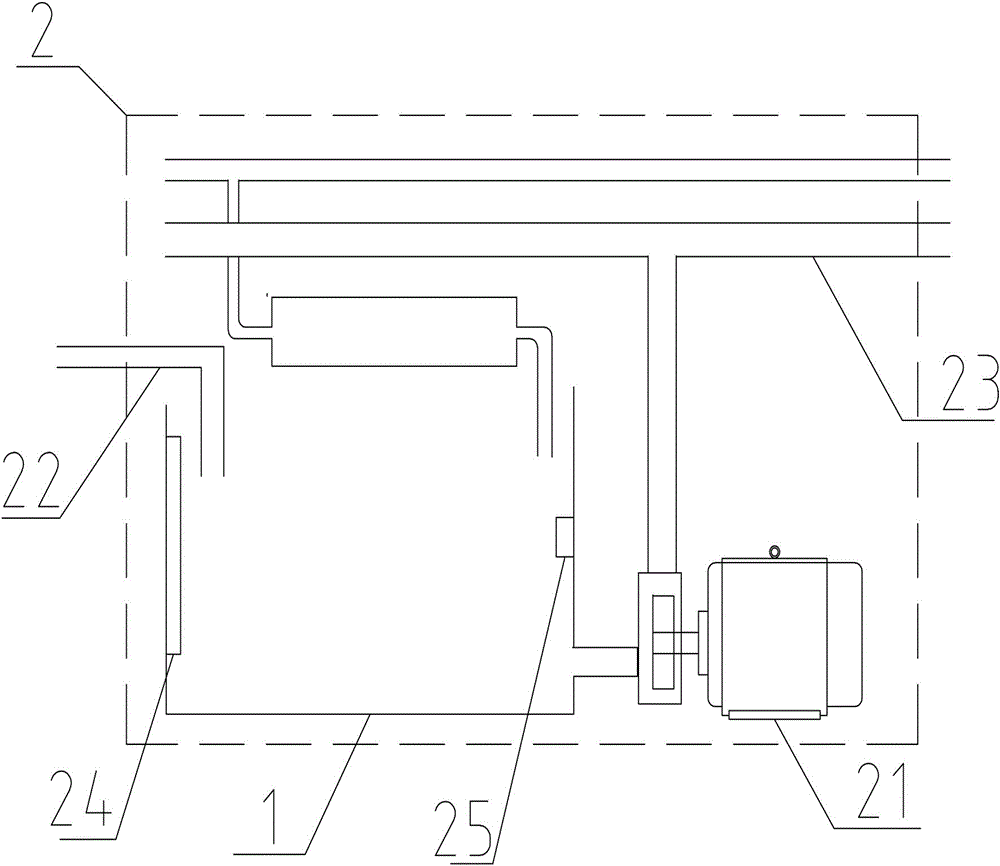

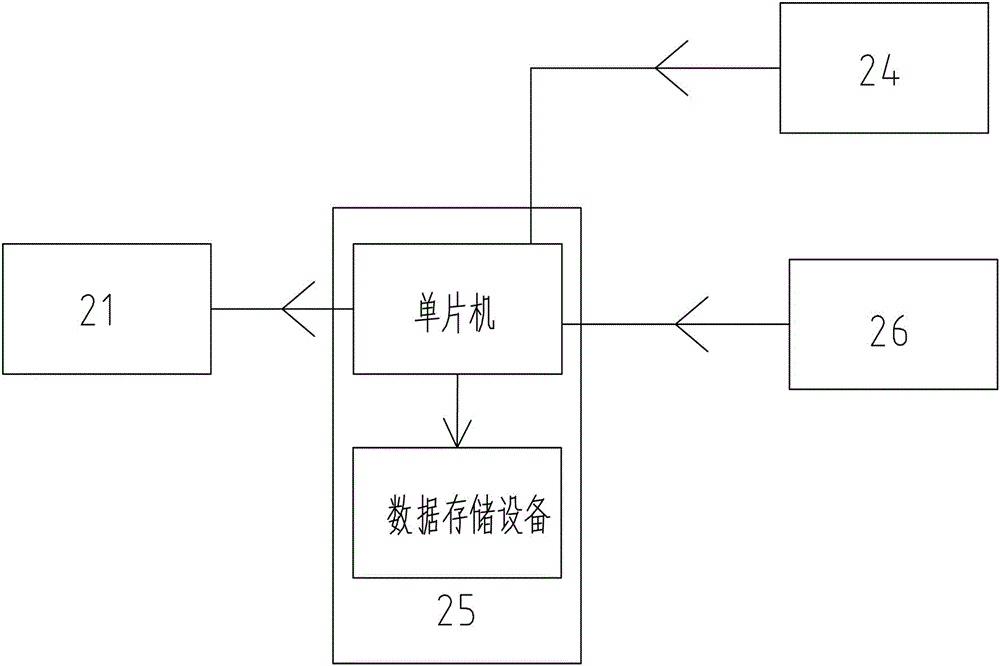

Wallpaper printing circulating water auto-control equipment

InactiveCN104372826AIncrease powerLow powerService pipe systemsPump controlAutomatic controlWallpaper printer

Wallpaper printing circulating water auto-control equipment comprises a water tank and an automatic circulating water supply device. The automatic circulating water supply device comprises a control device, a variable frequency water pump, a water supply pipe and a circulating water pipe. The control device comprises a liquid level sensor and a controller. A water outlet of the water supply pipe is communicated with the water tank. A water inlet of the circulating water pipe and a water outlet thereof are communicated with the water tank. The variable frequency water pump is disposed at a water inlet of the circulating water pipe. The liquid level sensor is disposed on the inner wall of the water tank and electrically connected with the controller. The controller is electrically connected with the variable frequency water pump. The wallpaper printing circulating water auto-control equipment has the advantages that the design is reasonable, operating is simple, and water can be automatically supplied according to needs of a wallpaper printer.

Owner:湖北浩博特装饰材料有限公司

Whole wallpaper printing machine

ActiveCN106335273BImprove the quality of decorationHigh precisionRotary pressesPrinting press partsWallpaper printerEngineering

The invention provides a whole-piece wallpaper printer. The whole-piece wallpaper printer comprises a reeling device, an unreeling device and at least one group of impression device located between the reeling device and the unreeling device; each group of impression device consists of a printing device and a dryer heating device; the groups of impression devices are connected through transmission guide rolls; the side of each printing device is provided with a scraper device and an ink supplying device; a material unreeling traction part is arranged between the impression device and the unreeling device; and a material reeling traction part is arranged between the impression device and the reeling device. The whole-piece wallpaper printer is characterized in that a cooling mechanism is additionally arranged on the dryer heating device; and a pattern alignment compensation mechanism is connected to the rear part of the cooling mechanism. The whole-piece wallpaper printer has the beneficial effects that the application width of each device is changed, and multiple detection mechanisms and adjustment mechanisms are arranged, so that real-time detection and real-time adjustment are realized, and therefore whole-piece wallpaper applicable to a whole wall surface can be manufactured; decoration quality is greatly improved; the quality of the wallpaper product is far better than that of current narrow-width wallpaper; precision of a manufacture process is high; printing quality is good; and machining efficiency is high.

Owner:ZHEJIANG MEIGE MACHINERY

Supplying media to a wallpaper printer

InactiveUS7217049B2Eliminate stock-out, stock-control/ordering and stock obsolesces issuesEliminate inventoryInking apparatusOther printing apparatusWallpaper printerFree edge

The invention provides a method of supplying a media web to a wallpaper printer. The method involves opening a reusable case and placing into the case a core onto which has been located a supply roll of blank wallpaper media. The core is supported for rotation within the case before it is closed. A free edge of the roll is placed between a pair of rollers and past an edge of the open case, then with the rollers located within the case and on either side of the web the case is closed and loaded into a printer. In some embodiments, a pair of resilient bias devices hold the rollers in proximity.

Owner:MEMJET TECH LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com