Crowned strip conveying device

A conveying device and crown tape technology, which is applied in transportation and packaging, winding strips, function indication, etc., can solve the problems of crown tape supply interruption, tire production interruption, installation trouble, etc., to maintain continuity and ensure efficiency , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

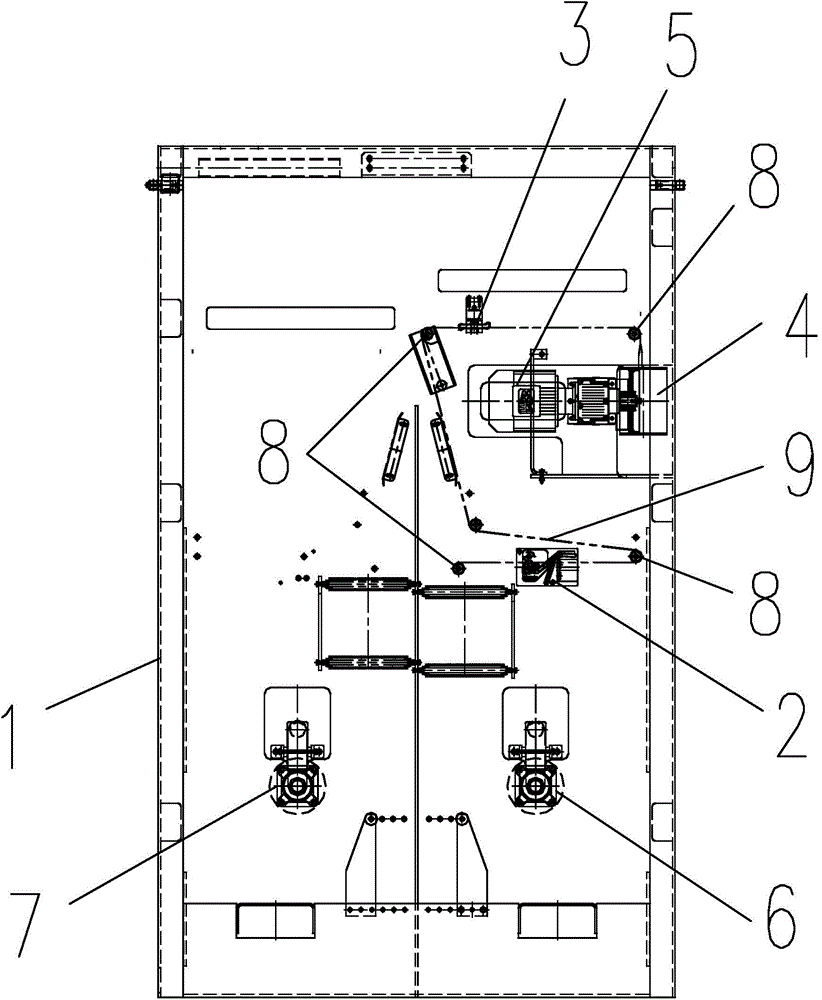

[0011] The crown belt conveying device of the present invention, as figure 1 As shown, it includes a frame 1, on which a material wheel, a material detection device 2, a material breaking clamping device 3 and a guide motor 5 equipped with a guide roller 4 are installed, and the material detection device 2 is located between the material wheel and the breaker. Between the material clamping device 3, the material wheel includes the first material wheel 6 and the second material wheel 7 located on both sides of the frame 1, the machine on both sides of the material detection device 2 and the two sides of the broken material clamping device 3 Guide rollers 8 are installed on the frame 1, and the material detection device 2 is electrically connected with the clamping device 3 for cutting off the material and the motor 5 for guiding.

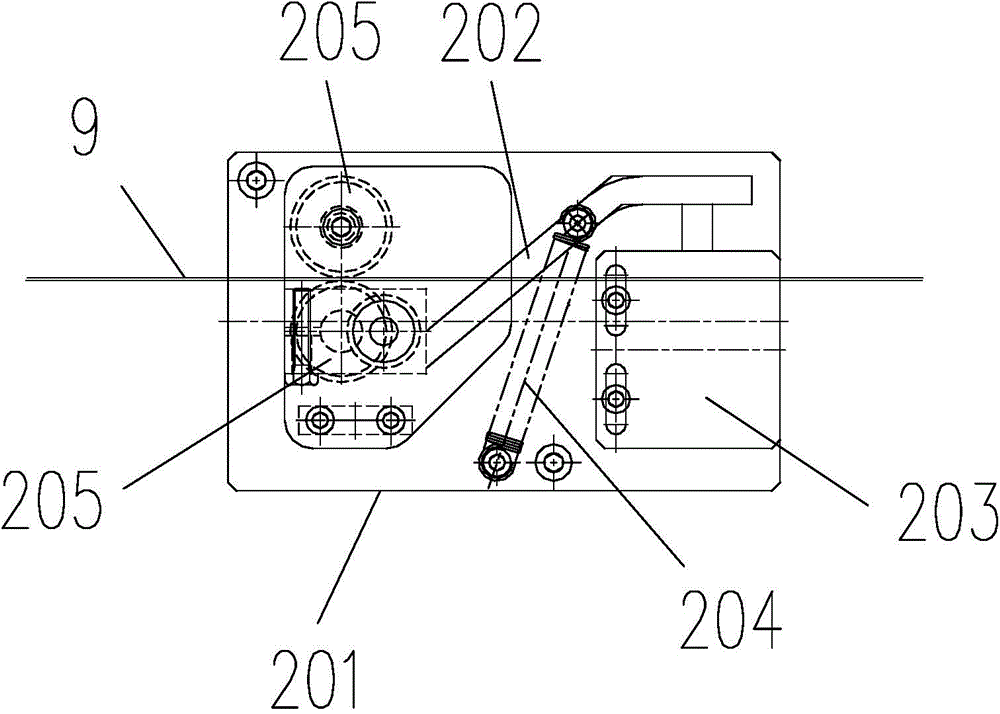

[0012] Such as figure 2 As shown, the material detection device 2 includes a detection base 201, a trigger lever 202, a micro switch 203, and a tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com