Anti-cracking door

A technology for anti-cracking and door panels, which is applied in the direction of door leaves, windows/doors, and special equipment for doors/windows. It can solve the problems of time-consuming, labor-intensive, and cost-increasing, and achieve the effects of avoiding cracking, saving manpower, material resources, and time costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

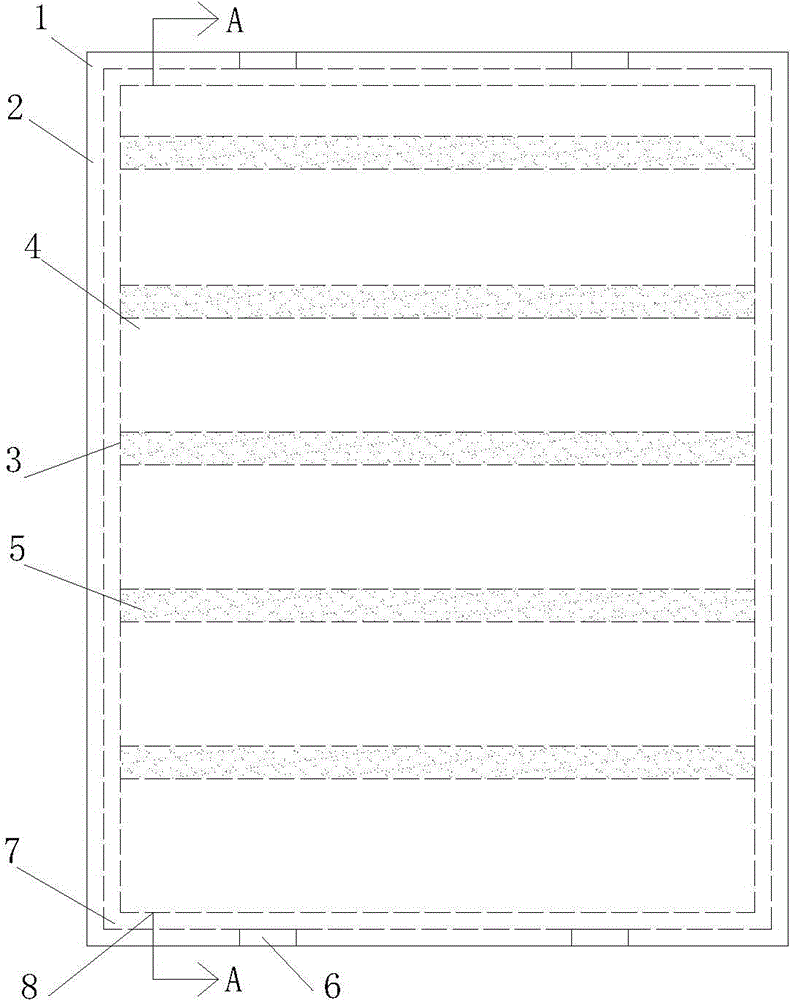

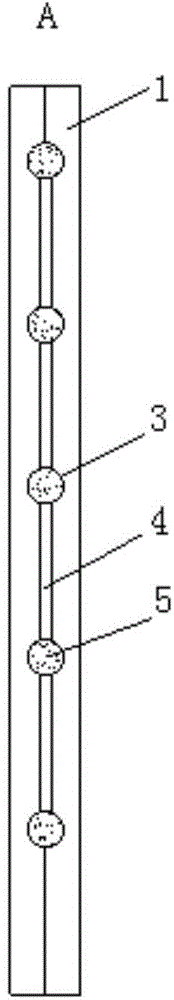

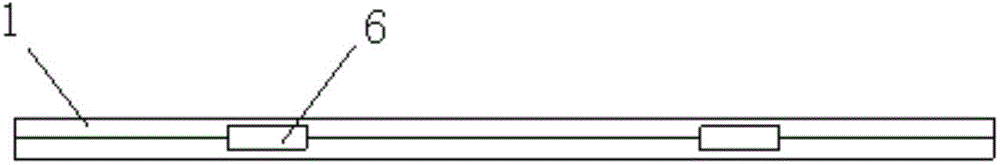

[0014] Example. A crack-resistant door constituted as figure 1 , figure 2 and image 3 As shown, it includes two layers of overlapping door panels 1 and a bonding area 2 connecting the two door panels 1. Each layer of door panels 1 includes a central area 8 corresponding to the shape of the door panel. The central area 8 is provided with a number of horizontal paint-coated The filling through hole 3 of the layer is provided with a phase change constant temperature material 5 in the filling through hole 3, the bonding area 2 is located near the filling through hole 3, and the outer ring of the central area 8 is provided with an air channel 7, and the air channel 7 is connected to several air inlets. Hole 6. An air channel 7 is provided between the adhesive zone 2 and the central zone 8 . Air in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com