A kind of test method for depositing sulfur corrosion of oil well pipe material and its test fixture

A corrosion test and sulfur deposition technology, which is used in analysis of materials, weather resistance/light resistance/corrosion resistance, measurement devices, etc., and can solve problems such as lack of reliability in test results, uneven corrosion of samples, and inability to effectively simulate corrosion behavior.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The 028 iron-nickel-based alloy for oil casing is selected as the test material, and its main components are: 28% Cr, 30% Ni, 3% Mo, 1% Cu, and the balance of Fe. Process it into a round bar with a diameter of 8 mm and a length of 10 cm. The center of both ends of the sample is processed with a 120° conical hole, then polished with 600# sandpaper, cleaned with acetone ultrasonically, and weighed with a balance with an accuracy of 0.1 mg.

[0053] The simulation solution was prepared according to the formation water composition of an oilfield, and the Cl in the solution - The concentration is about 100g / L, and the main components of the solution are shown in Table 1.

[0054] Table 1 Composition and content of simulated solution

[0055] Element

[0056]Sieve the sulfur powder with a 400-mesh standard sieve, take the sulfur powder below 400 mesh, stir and mix it with the simulated solution according to the aforementioned method, and make it into a paste. Put ...

Embodiment 2

[0058] The G3 nickel-based alloy for oil and casing is selected as the test material, and its main components are: 50% Ni, 22% Cr, 8% Mo, 2% Cu, and the balance of Fe. Process a round bar with a diameter of 8 mm and a length of 10 cm, and process a 120° conical hole at the center of both ends of the sample, then polish it with 600# sandpaper, clean it ultrasonically with acetone, and weigh it with a balance with an accuracy of 0.1 mg.

[0059] The composition of the simulated solution is shown in Table 1, the Cl in the solution - The concentration is about 50g / L.

[0060] Table 2 Composition and content of simulated solution

[0061] Element

NaHCO 3

Na 2 SO 4

CaCl 2

MgCl 2

KCl

NaCl

Content, g / l

1.2

1.0

19.8

2.0

0.5

58.6

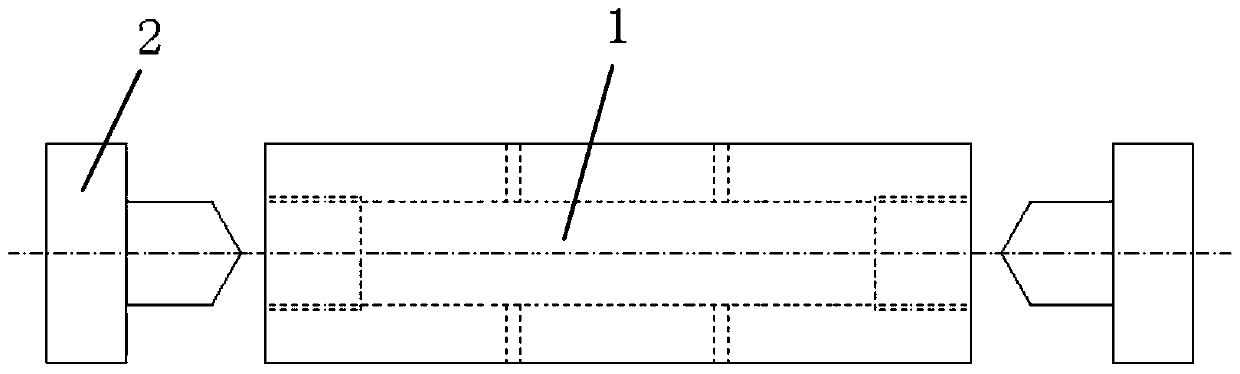

[0062] The preparation method of sulfur powder is as above. Put the sample into figure 1 In the shown sleeve with an inner diameter of 16mm, the diameter of the hole on the sleeve is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com