A deep oil-contaminated soil simulation repair device and its application

An oil-polluted, deep-seated technology, applied in the field of contaminated soil remediation, achieves the effect of low cost, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

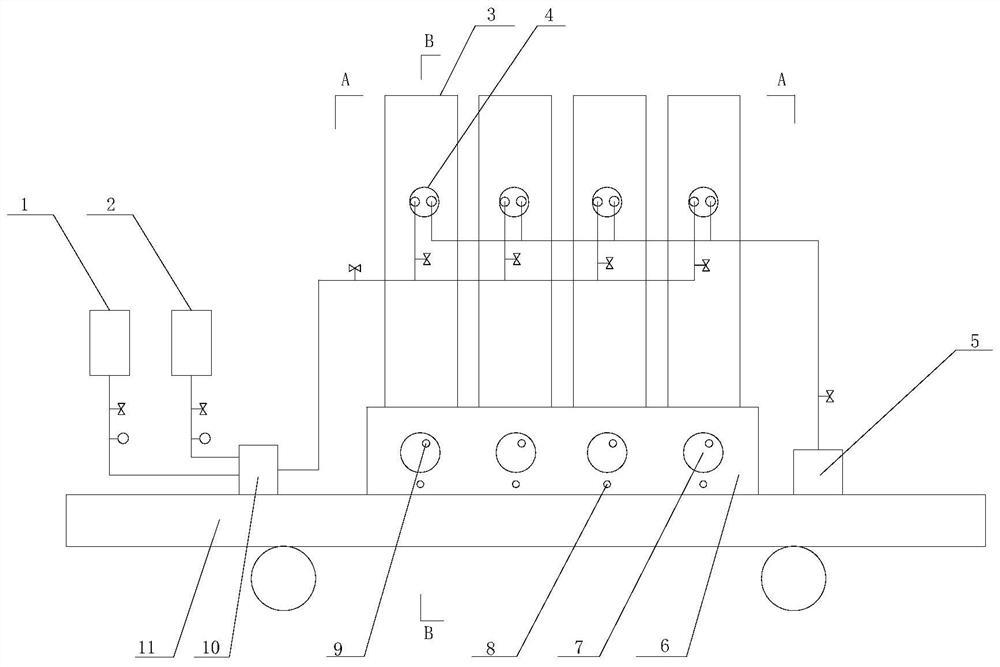

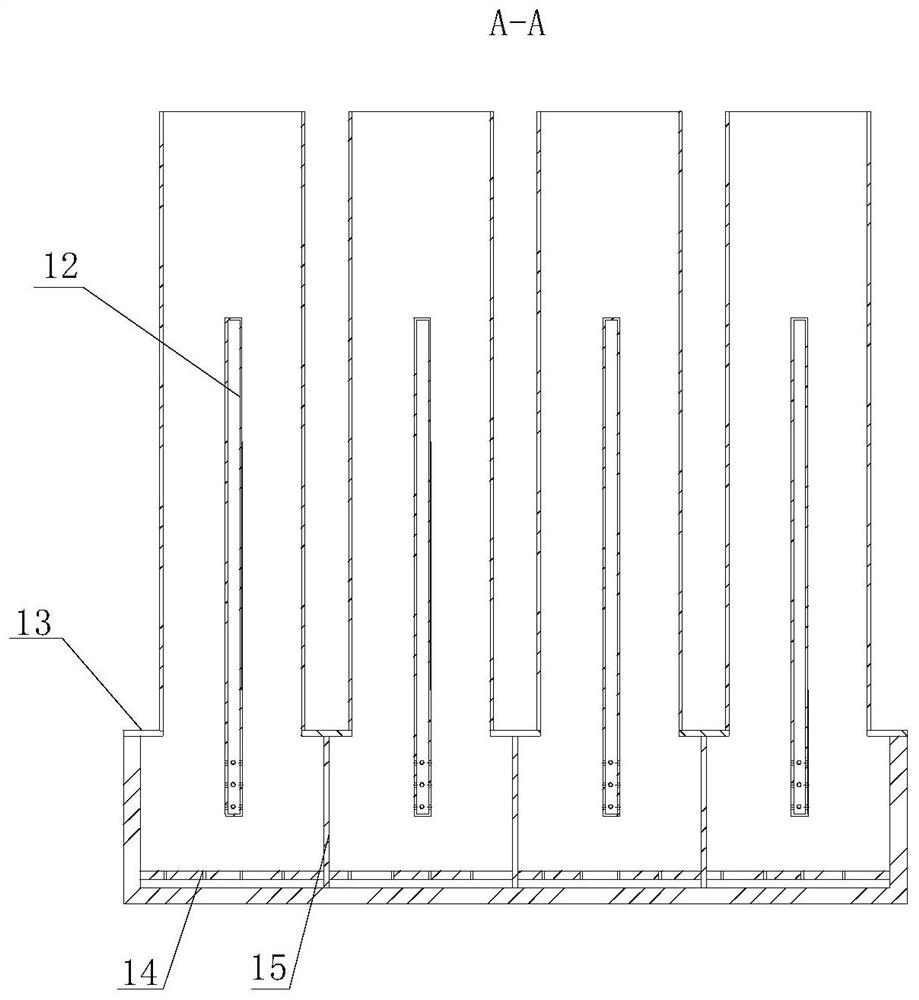

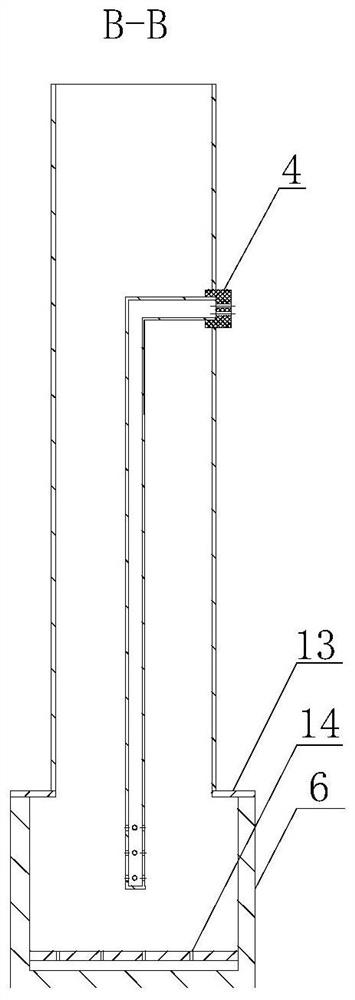

[0027] exist Figure 1~3Among them, the present invention relates to a deep petroleum-contaminated soil simulation restoration device. A contaminated layer box 6, an air compressor 5, and a peristaltic pump 10 are installed on a base 10, and rollers are installed at the bottom of the base 10 to facilitate the device to move back and forth. The inside of the polluted layer box 6 is divided into at least one independent repair box by a partition 15, and the number of repair boxes is processed according to the actual situation. In this embodiment, the inside of the polluted layer box 6 is divided into four independent repair boxes by a partition 15. Each repair box is 19cm long, wide 30cm, and high 30cm. Oil-contaminated soil is filled respectively in each repair box. Drain board 14 is installed at the bottom of the repair box. Excess water is drained to the bottom of the repair box, and discharged from the device through the drain pipe 8. On the front surface of the contaminated...

Embodiment 2

[0030] In this embodiment, the wall of the sample tube 12 in this embodiment is provided with two layers of liquid outlet holes at intervals in the axial direction, each layer is spaced at 10 mm, and the diameter of the liquid outlet hole is 1 mm. .

Embodiment 3

[0032] In this embodiment, the pipe wall of the sampling tube 12 is axially provided with 8 layers of outlet holes at intervals, each layer is 20mm apart, and the diameter of the outlet holes is 3mm. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com