A laboratory test device for simulating the flow field of salt rock karst cavity construction

A laboratory simulation, salt rock karst cavity technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problem of slow construction speed, insufficient, and difficult dissolution of the salt body on the inner wall of the karst cavity. Grasp and other issues to achieve the effect of strong reliability, small size and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

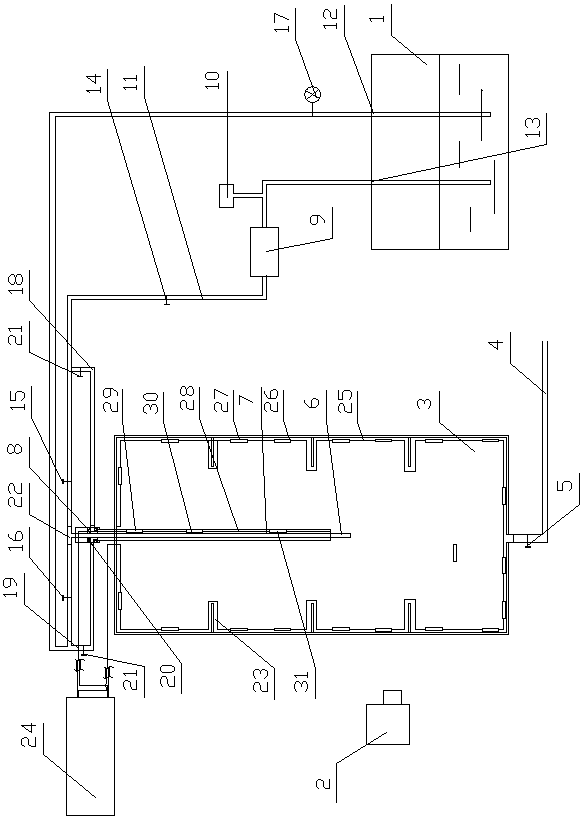

[0034] Such as figure 1 As shown, the present invention includes a water tank 1, an image recorder 2, a simulated salt karst cavity 3 made of organic glass, and a signal transmitting and receiving processor 24. The inner wall of the simulated salt karst cavity 3 is provided with a simulated interlayer device 23, and the image recorder 2 is provided On one side of the simulated salt karst cavity 3, the image recorder 2 is a digital video camera and / or camera.

[0035] The bottom of the simulated salt karst cavity 3 is provided with an outlet pipe 4, the first valve 5 is connected to the outlet pipe 4, a central pipe 6 is vertically arranged in the simulated salt karst cavity 3, and an intermediate pipe 7 is placed outside the central pipe 6. 7 is connected to the central pipe 6 through the hanger 8, and both the central pipe 6 and the intermediate pipe 7 extend upward to simulate the salt karst cavity 3.

[0036] The water tank 1 is provided with a circulating water inlet 12 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com