Electric high-rise glass wiper

A glass wiper, electric technology, applied in cleaning equipment, household appliances, applications, etc., can solve the problems of low efficiency, inconvenient to remove stains, time-consuming and laborious, and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

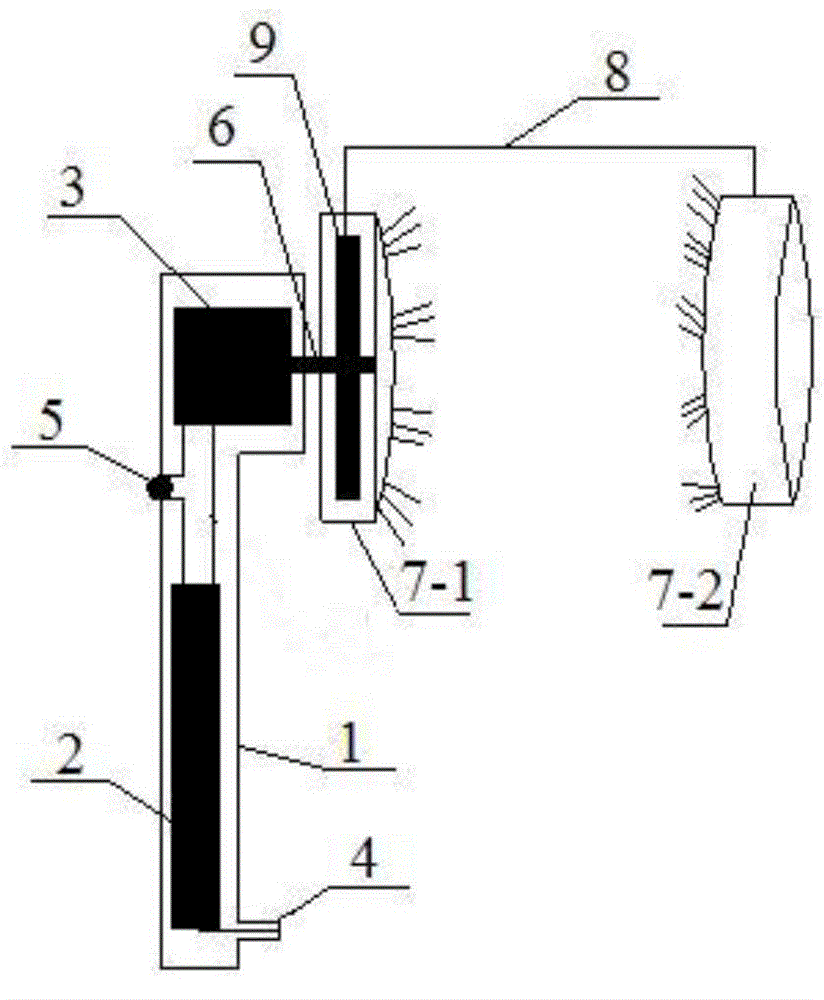

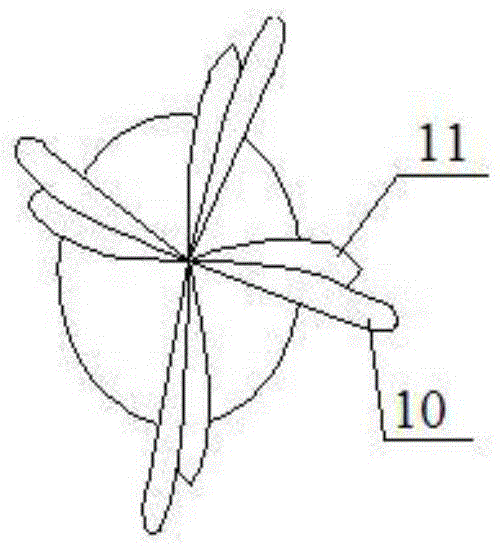

[0017] Such as figure 1 , figure 2 The shown electric glass wiper for high-rise buildings includes a handle 1 with a cavity inside and a cleaning cylinder unit. A rechargeable battery 2 is placed in the lower part of the cavity of the handle 1. In the cavity of the handle 1 The upper part is provided with a motor 3, and the outer lower end of the handle 1 is provided with a plug 4 for charging. A switch 5 is provided, and the switch 5 is located on the outer surface of the handle 1, and the output shaft of the motor 3 is connected with a rotating shaft 6; the cleaning cylinder unit includes a first cleaning cylinder 7-1 and a second cleaning cylinder 7- 2. The first cleaning cylinder 7-1 is installed on the rotating shaft 6, and the second cleaning cylinder 7-2 is connected to the first cleaning cylinder 7-1 through a long line 8. The first cleaning cylinder 7-1 The interior of the first cleaning cylinder 7-1 is equipped with a magnet 9, the surface of the first cleaning cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com