Shield tunneling machine mud cake removing device and removing method

A technology of cleaning device and shield machine, which is applied in the direction of cleaning methods and tools, cleaning methods using tools, cleaning methods using liquids, etc., can solve the problem of affecting the speed of shield machine tunneling, not having the conditions for stopping and cleaning, and the cleaning ability is not enough In place and other issues, to avoid the risk of manual cleaning, save economic resources, delay the effect of wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments, but the embodiments of the present invention are not limited thereto.

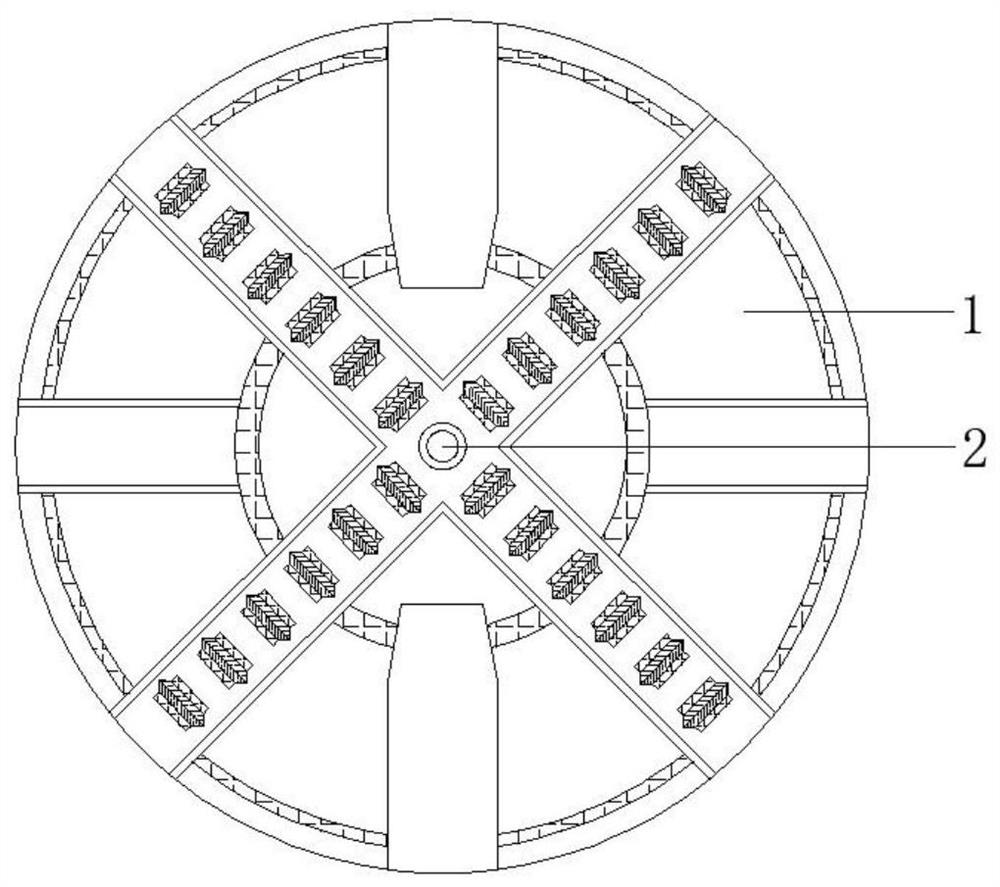

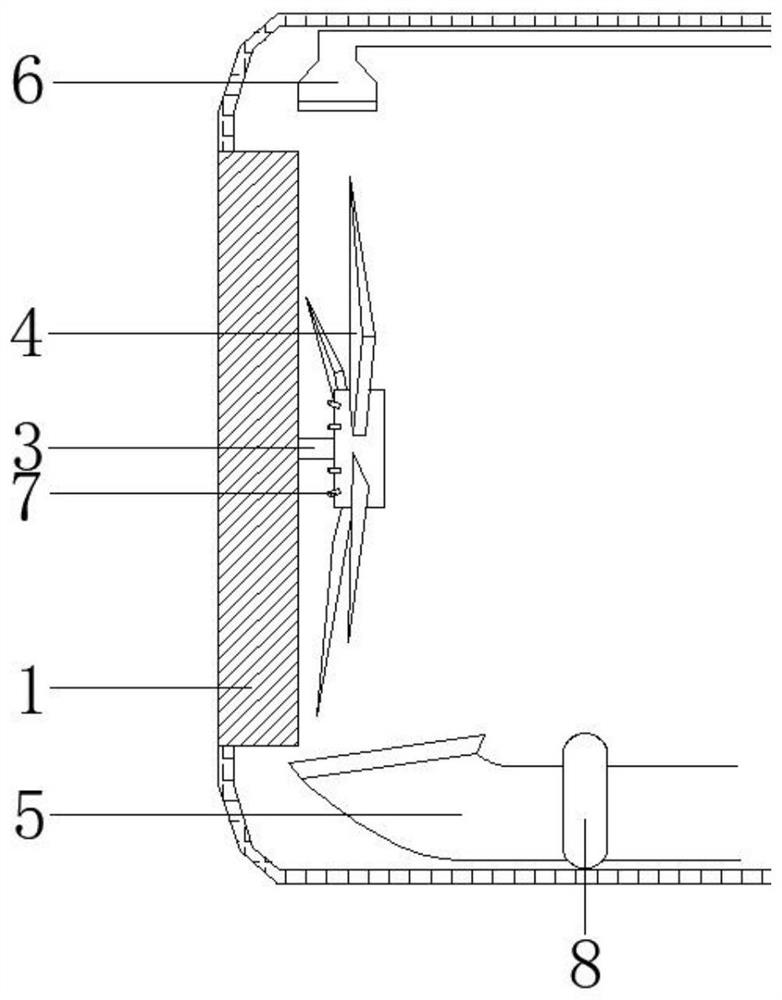

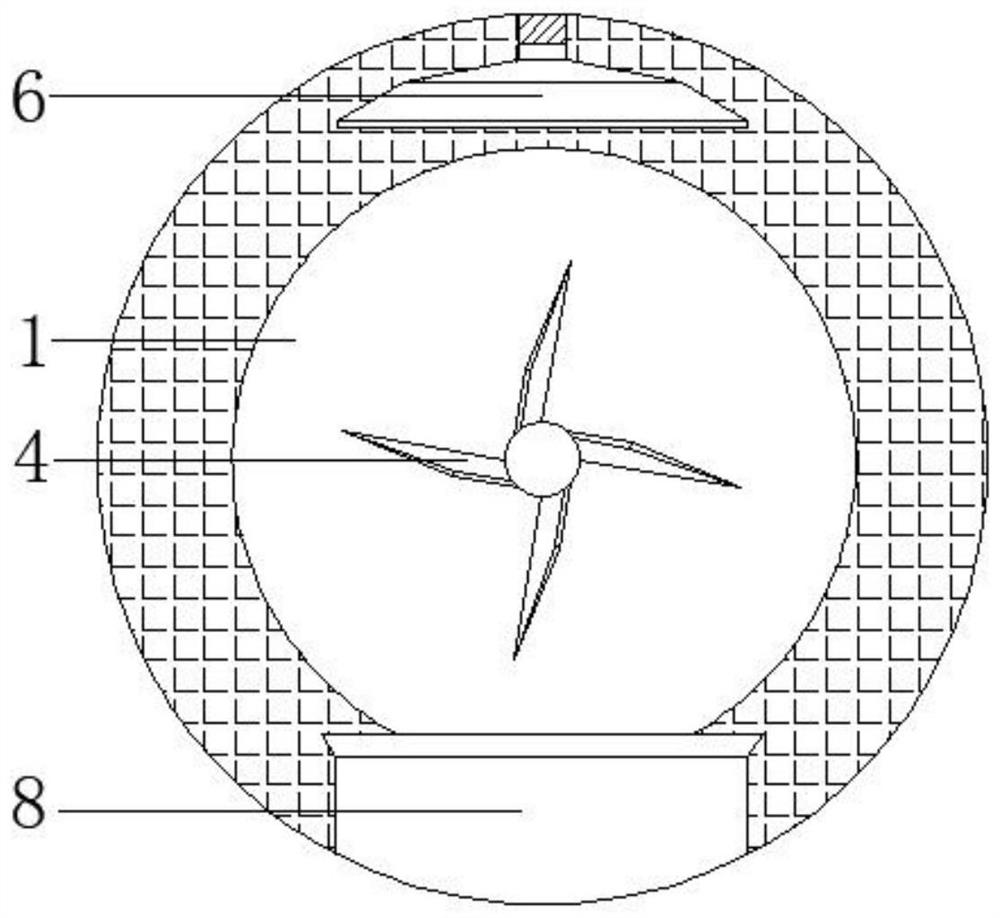

[0038] Such as Figure 1-Figure 2 As shown, the shield machine mud cake removal device of the present invention, the shield machine mud cake removal device includes a fan 6, a dredger 5 and a main cleaning turntable;

[0039] Wherein, the main cleaning turntable is connected with the cutter head panel of the shield machine, and is used to remove mud cake from the cutter head of the shield machine;

[0040] The fan 6 is arranged behind the cutterhead panel and above the main cleaning turntable for generating cold wind;

[0041] The mud suction machine 5 is arranged behind the cutterhead panel and below the main cleaning turntable for generating suction.

[0042] Preferably, the drill ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com