Farm-oriented resonance turning air outlet grain screening machine

An air screen and air frame technology, which is applied in the field of agricultural resonant resonant wind screen grain machines, can solve the problems of troublesome operation, single structure and function, increased cost and floor space, etc. High impurity efficiency and good impurity removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

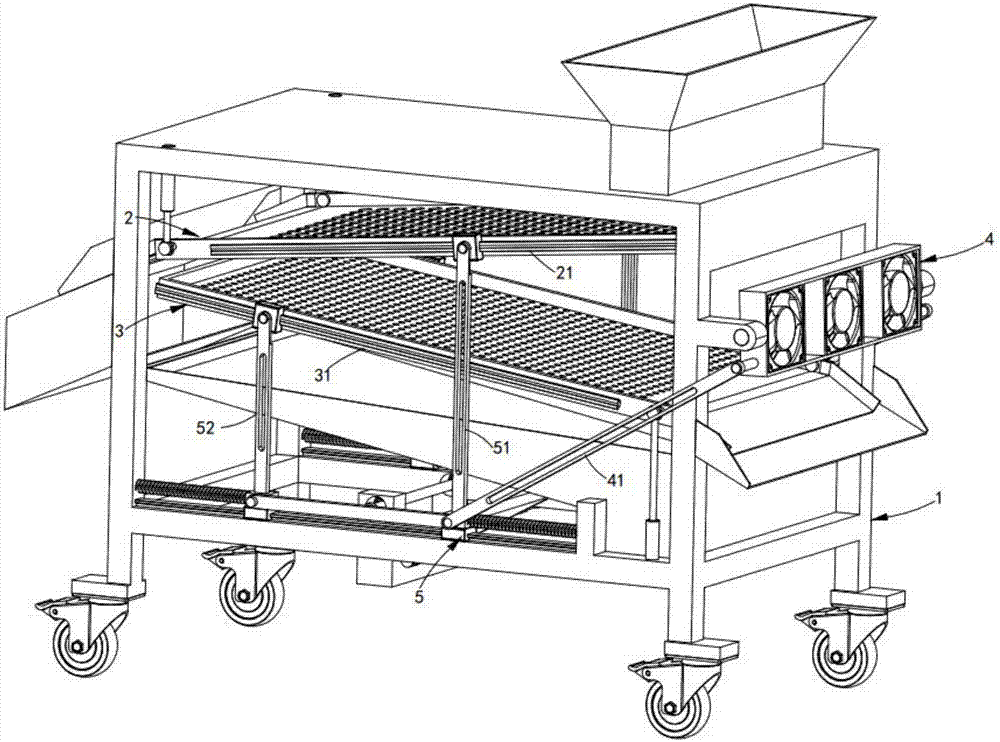

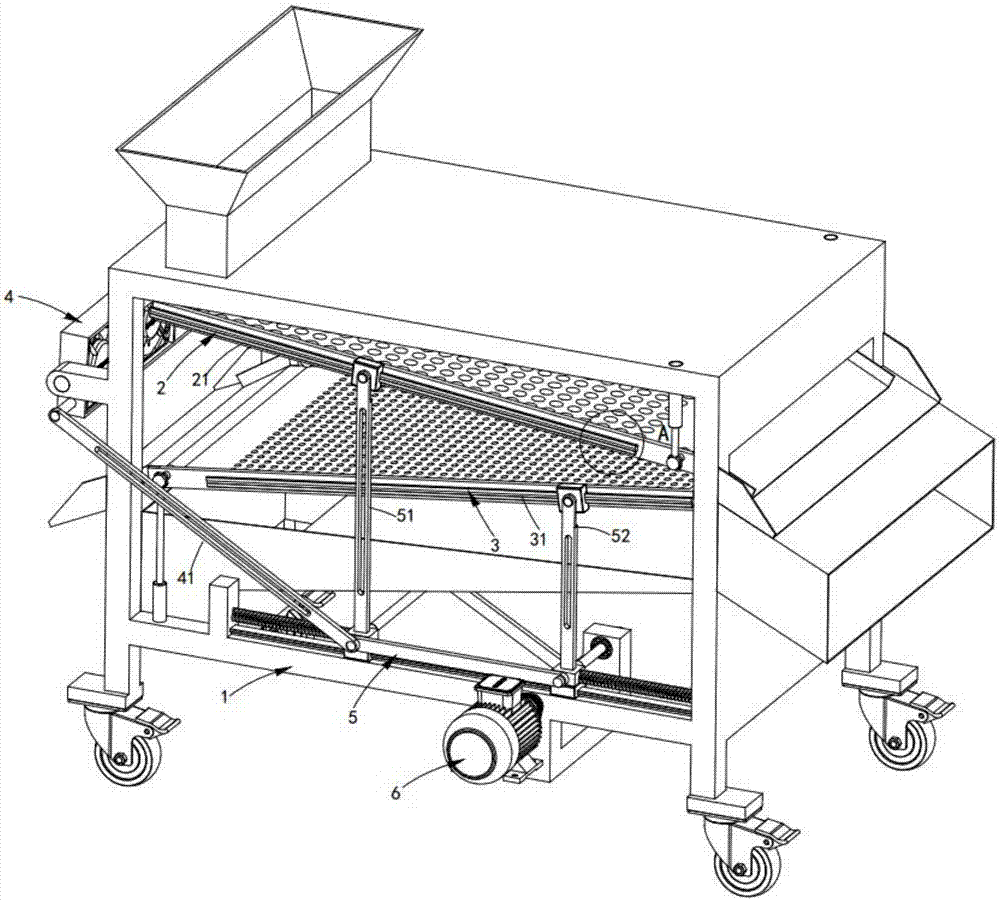

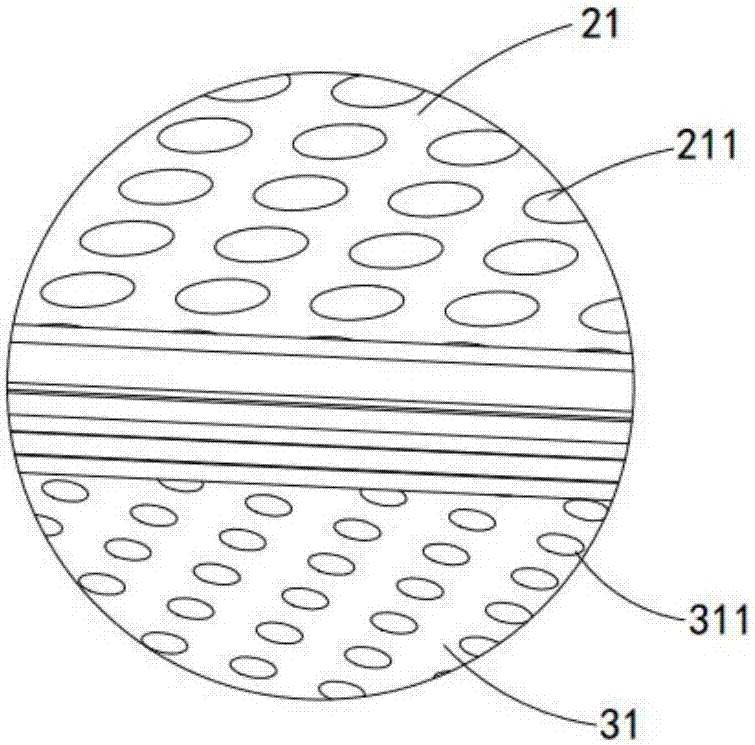

[0038] Such as figure 1 and figure 2 As shown, a kind of agricultural resonant wind-changing wind sifting machine includes a frame 1, a first screening mechanism 2, a second screening mechanism 3, a direction-changing wind blowing mechanism 4, a vibration mechanism 5 and a driving mechanism 6, and is characterized in that , the first screen 21 in the first screening mechanism 2 is obliquely arranged on the upper part of the frame 1, and the second screening mechanism 3 is provided at its lower end, and the second screen in the second screening mechanism 3 Net 31 is also provided for inclination;

[0039] The direction-changing air outlet mechanism 4 is arranged on one side of the frame 1, it is located between the first screening mechanism 2 and the second screening mechanism 3, and it is connected to the vibration mechanism through the first connecting rod 41. 5 hinged;

[0040] The vibrating mechanism 5 is arranged below the second screening mechanism 3, and it is hinged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com