Multistage separating and screening machine

A sorting and screening technology, which is applied in the direction of filtering, solid separation, and separating solids from solids with airflow, can solve the problems of high labor intensity and low efficiency of sorting work, and achieve the reduction of labor intensity, The effect of screening work efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

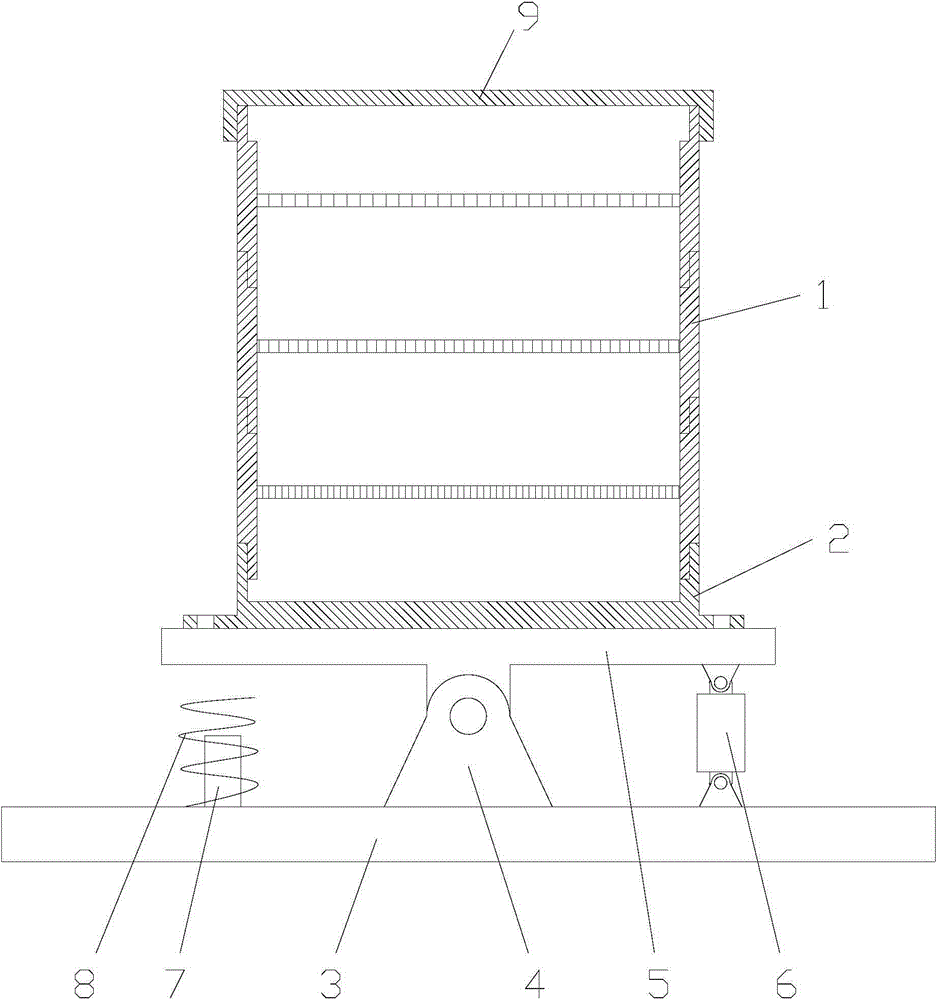

[0013] As shown in the figure, the multi-stage sorting and screening machine of the present embodiment includes a grading sieve group composed of two flat-bottomed sieving sieves 1 that can be detachably overlapped vertically (of course, the grading sieve group can also be composed of two, four, etc. More than two sorting screens), the lowermost sorting screen in the classifying screen group is provided with a material receiving tray 2;

[0014] It also includes a workbench 3, a hinged seat 4 arranged on the workbench, a swing plate 5 hingedly connected to the hinged seat, and a cylinder 6 hingedly connected to the workbench and the swing plate;

[0015] The receiving tray 2 is detachably connected to the swing plate 5 .

[0016] When sieving, put the products to be classified into the uppermost sorting sieve, and then start the cylinder 6 to push the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com