Rotary material sorting device

A sorting device and rotary technology, applied in sorting and other directions, can solve problems such as fine hole blockage, achieve the effect of facilitating reset work, solving frequent blockages, and reducing human resource costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

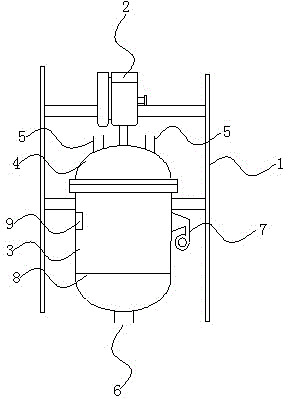

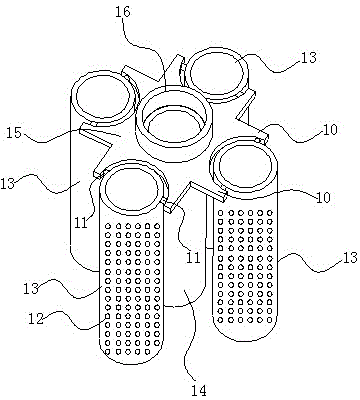

[0026] Such as Figure 1-2 As shown, it is a rotary material sorting device of the present invention, which includes a main body frame 1, a main body shell 3 installed on the main body frame 1, a detachable upper shell 4 installed on the top of the main body shell 3, and a rotatable The connecting sleeve 16 installed in the cavity of the upper shell 4, the motor 2 used to drive the connecting sleeve 16 to work, the rotating cylinder 14 inserted in the connecting sleeve 16 and rotating synchronously with it, are located in the cavity of the main body shell 3 The separation cylinder 13, the separation cylinder 13 is a hollow structure with an open upper end, a plurality of fine holes 12 are formed on the side wall of the separation cylinder 13, and the top of the upper shell 4 is installed with Facing the feed pipe 5 of the sorting cylinder 13, the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com