Lock sleeve cover cap riveting device and riveting method thereof

A cap and lock sleeve technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., to simplify manual operations and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

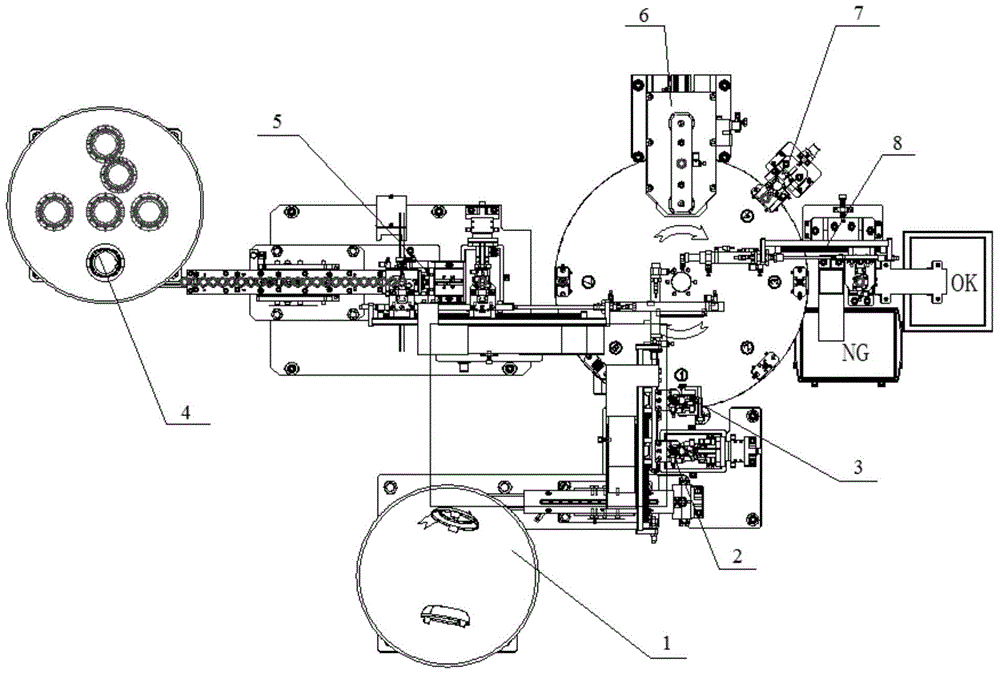

[0033] like figure 1 As shown, on the one hand, this embodiment relates to a lock sleeve cap riveting equipment, including a cap feeding device 1, a cap foreign product detection and foreign product discharge device 2, a cap in-position detection device 3, a lock sleeve feeding device 4, a lock Set of foreign product detection and foreign product discharge device 5, riveting device 6, riveting pressure detection device 7, finished product classification and collection device 8;

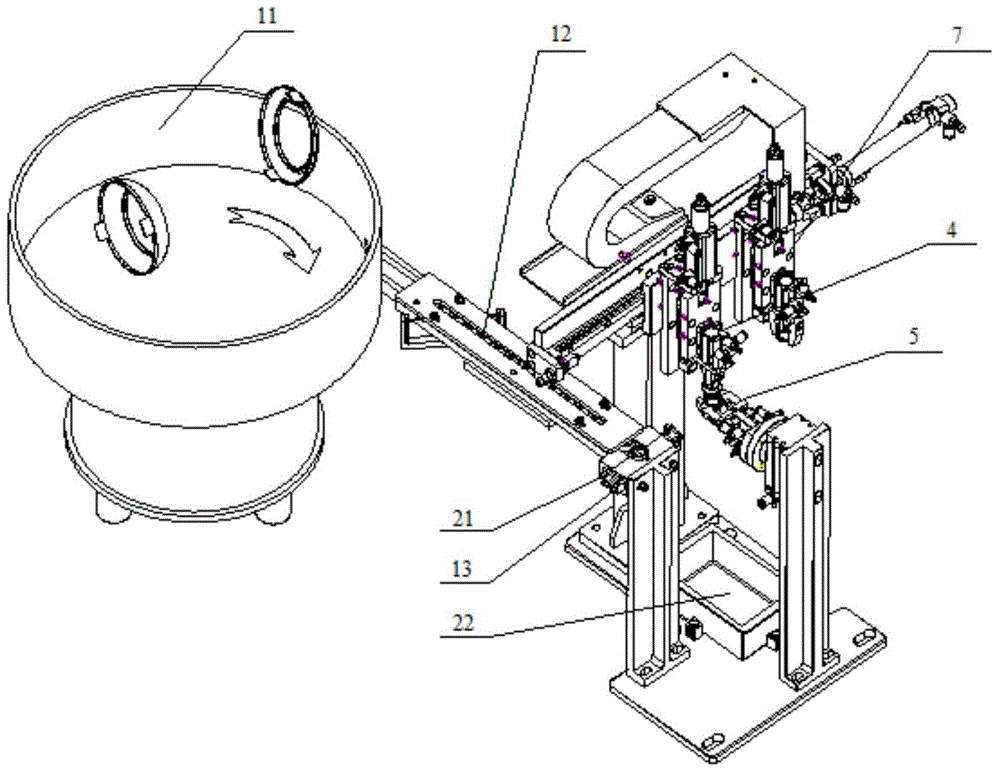

[0034] like figure 2 As shown, the cap feeding device 1 is mainly composed of a vibrating plate 11, a linear feeder 12, a first optical fiber sensor 13, and a manipulator 14. The vibrating plate 11 and the linear feeder 12 cooperate to perform single-channel feeding. The first optical fiber sensor is used to sense whether the cap material is in place. After the first optical fiber sensor 13 senses that the cap material is in place, the manipulator 14 grabs the in place cap to the detection station; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com