Mirror milling and top pressing device with deformation tracking and wall thickness measurement

A top pressure device and wall thickness measurement technology, applied in the direction of measuring/indicating equipment, milling machine equipment, manufacturing tools, etc., can solve problems such as difficulty in ensuring the wall thickness of the workpiece and milling quality, large deformation and vibration of the workpiece, and improve the quality of milling. The effect of processing quality, reducing local vibration and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments. However, those skilled in the art should know that the present invention is not limited to the specific embodiments listed, as long as it conforms to the spirit of the present invention, it should be included in the protection scope of the present invention.

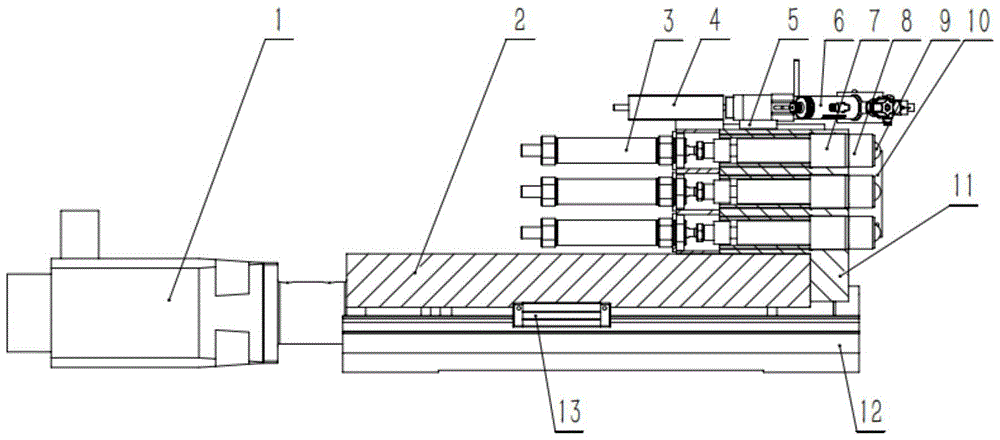

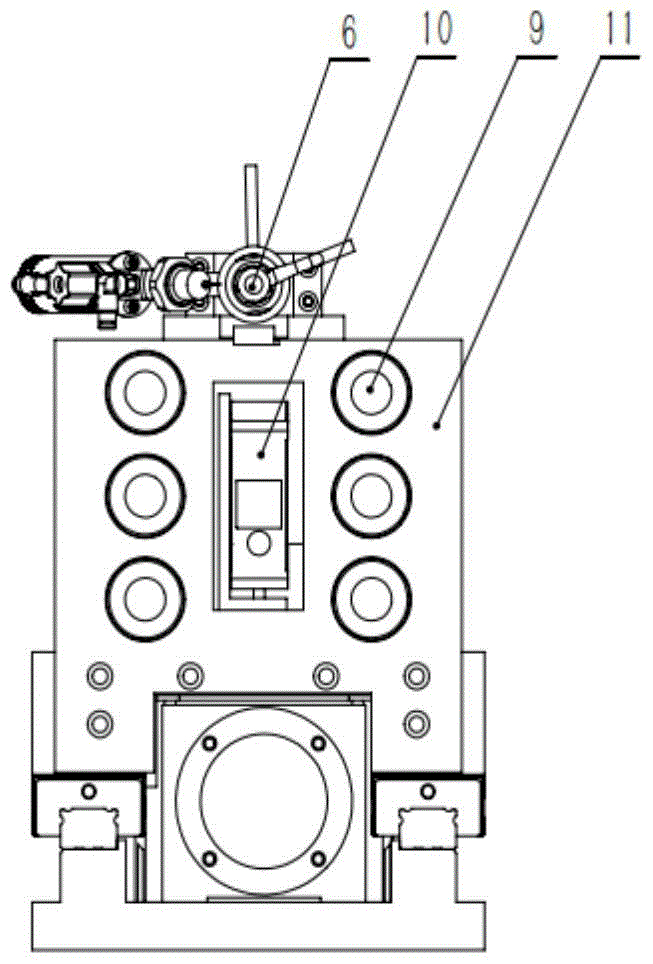

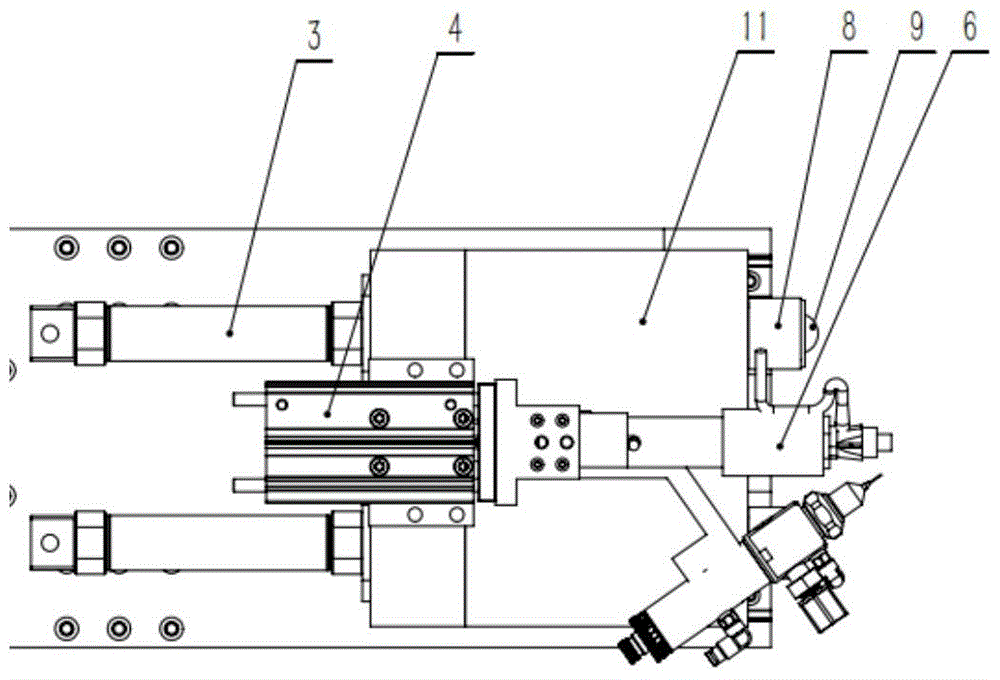

[0015] See attached figure 1 . The mirror image milling and pressing device with deformation tracking and wall thickness measurement functions of the present invention includes a servo drive system 1, a base 12, a pressing assembly, and a thickness measuring assembly. The system 1 is fixedly installed on the rear end of the slide plate 2 , and the slide plate 2 sits on the driving guide rail 13 and moves along the drive guide rail 13 .

[0016] The top pressure assembly is fixedly installed on the slide plate 2. There are several through holes parallel to the driving guide rail 13 on the mounting block 11 , usual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com