Double-layer support for flight vehicle assembling, transporting and docking

An aircraft, double-layer technology, which is applied to elevators, lifting devices, workbenches, etc., can solve the problems of single function and bulky support, and achieve the effects of good working performance, simple structure and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] The implementation of the present invention will be described below based on the drawings.

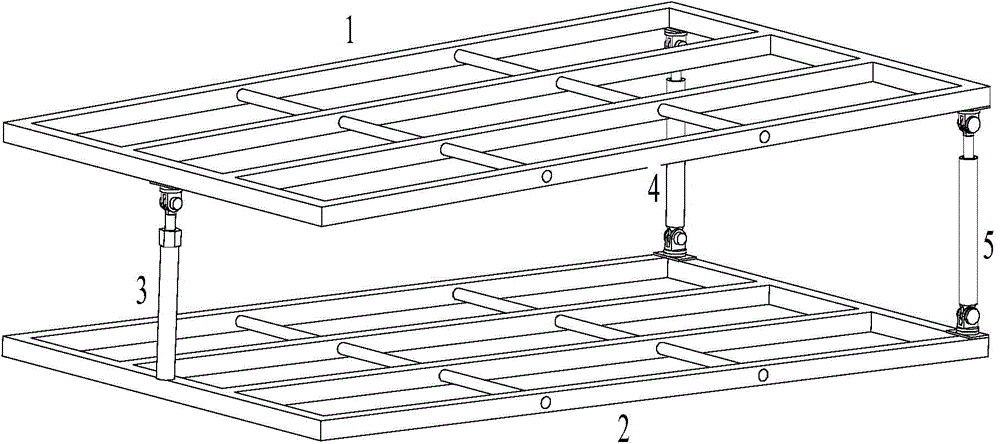

[0025] figure 1 Shows the overall structure of the double-layer bracket of the present invention, including the upper bracket 1, the lower bracket 2, the front lifting device 3, the rear lifting device 4, the rear lifting device 5 and the connecting mechanism 6. The upper bracket 1 and the lower bracket 2 are rectangular in shape , The front end is provided with a lifting device, namely the front lifting device 3 (the front end refers to the end where a front lifting device 3 is installed, and the front and rear directions used below are divided according to this). The lifting device of the present invention is a hydraulic lifting device, The variable end is a piston rod, and the fixed end is a piston sleeve. There is a lifting device on the left and right of the rear end. The lower end of the front lifting device 3 is directly fixed (welding method can be used) on the middle part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com