Plate turning-over type sorting device

A sorting device and flip-pan technology, which is applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of difficult linear sorting, increased production and maintenance costs, and increased control difficulty, and achieves flexible layout and cost. Inexpensive, reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

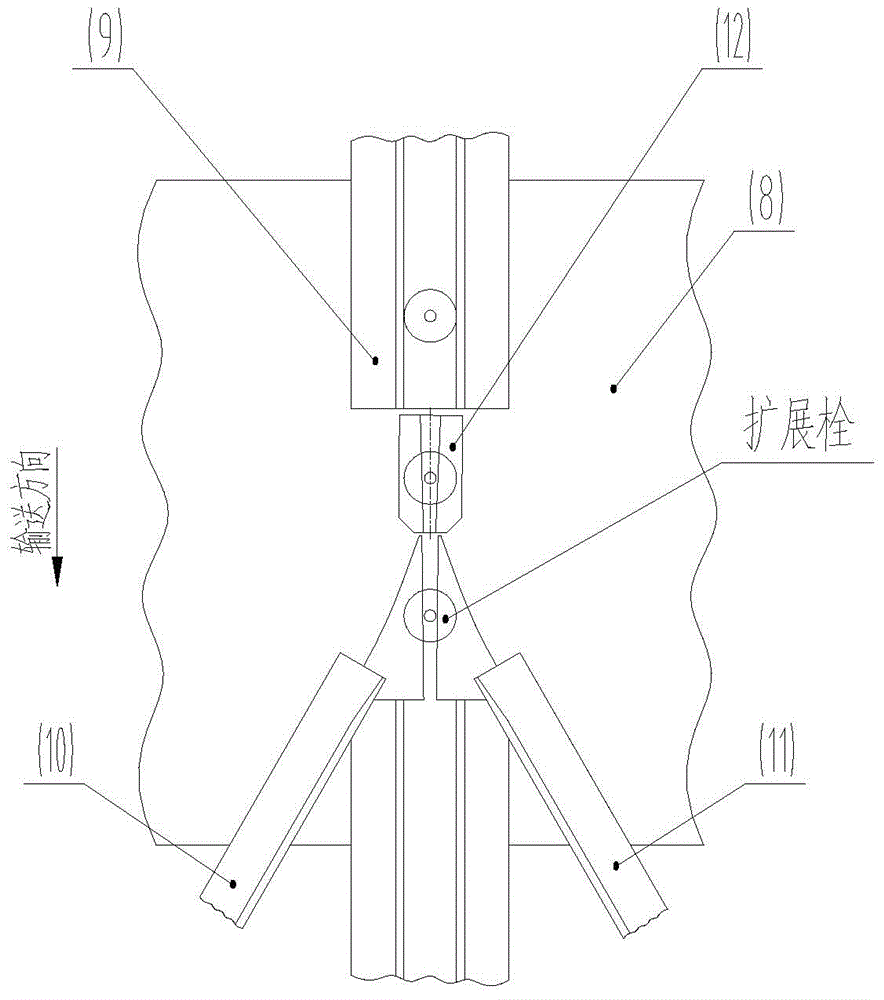

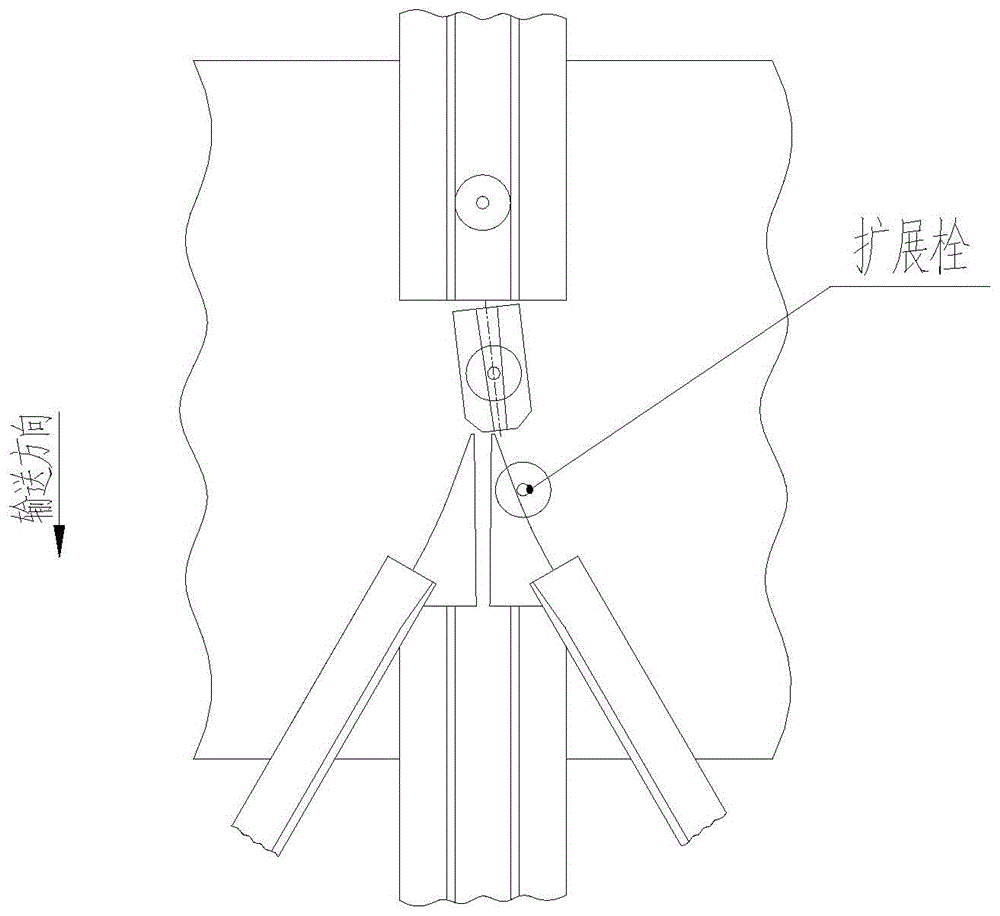

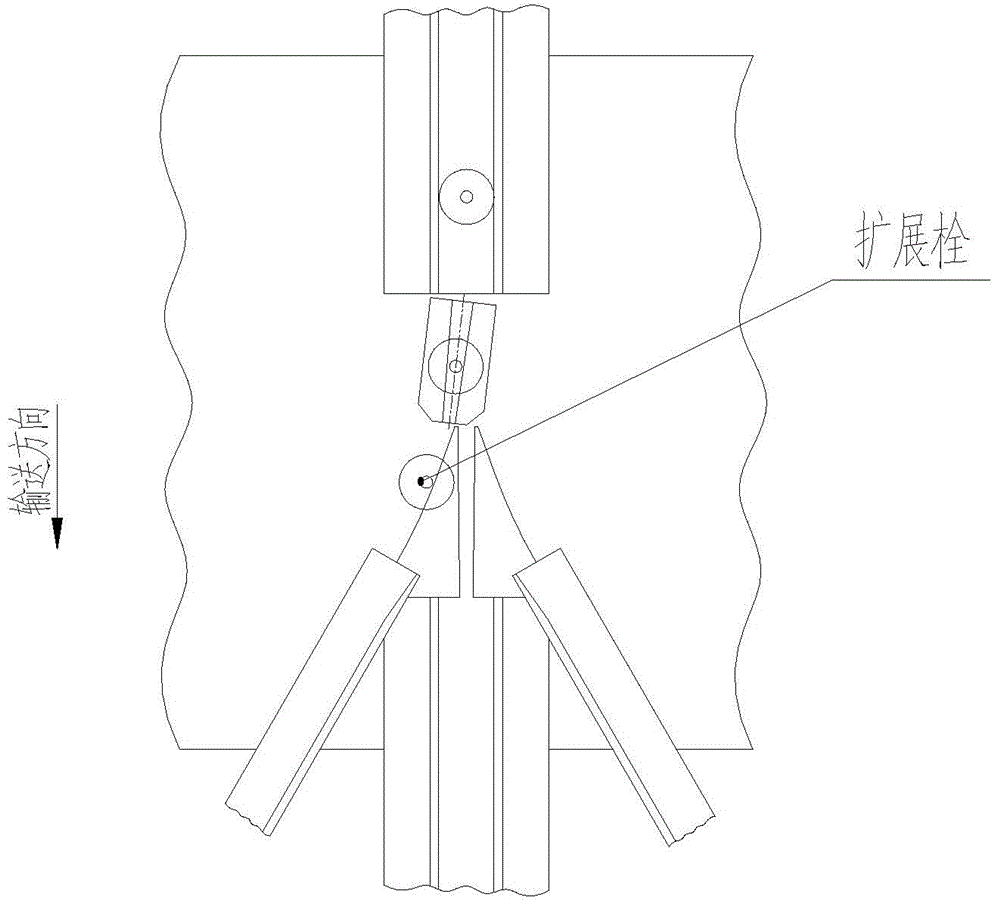

[0016] A kind of turntable type sorting device, the feature of the present invention is that it comprises a frame 8 and a transmission device 7 arranged on both sides of the frame 8, the transmission device 7 drives the guide rail movement of the guide rail pair 4, and the guide rail of the guide rail pair 4 is connected to the bracket 3 , the bracket 3 is hinged with the material tray 1; a switch device 6 is fixed at each sorting port on the frame 8; the slider of the guide rail pair 4 is provided with an expansion bolt 5, and the slider of the guide rail pair 4 passes through the hinged connecting rod 2 is hingedly connected with the material tray 1; among them, the expansion bolt 5 is fixed on the slider of the guide rail pair 4; the switch device 6 is composed of the main track 9, the fork track I10 and the fork track II11 with opening angles located on both sides of the main track 9 respectively , Commutation blocks 12 arranged between the main rails 9. The transmission d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com