Circular plane percussion table

A plane and shaker technology, applied in the field of vibrating bed and circular plane vibrating shaker, can solve the problems of large occupied area, low sorting accuracy, small processing capacity of diamond-shaped shaker table, etc. Conducive to the effect of sinking and simple excitation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

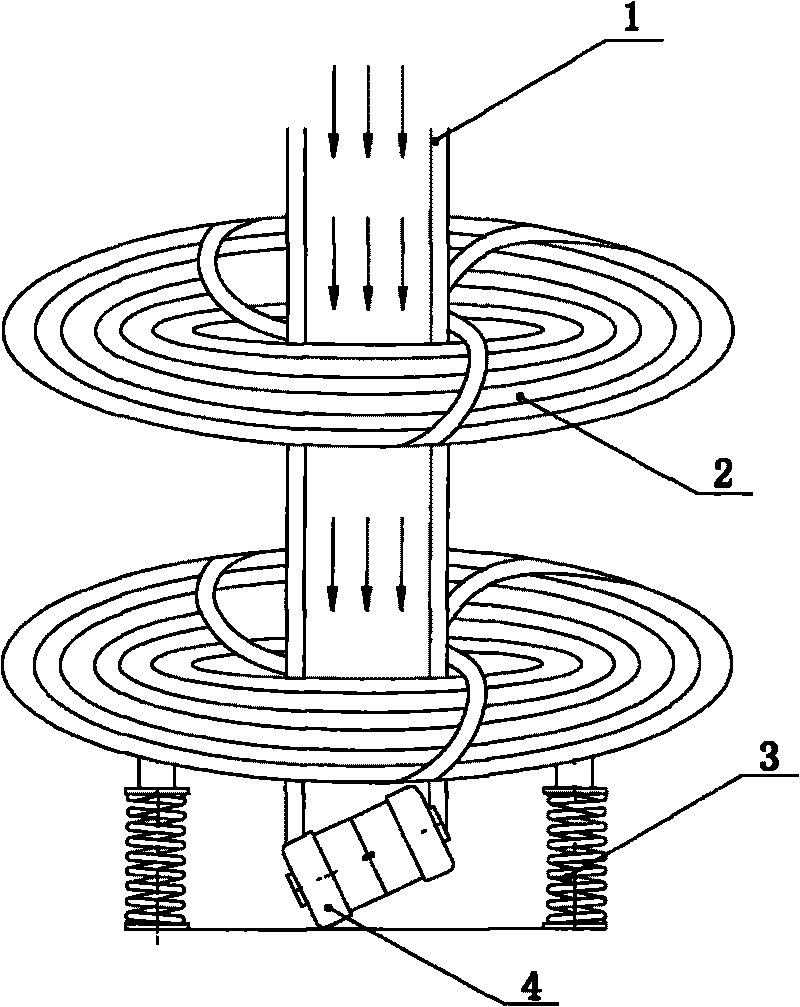

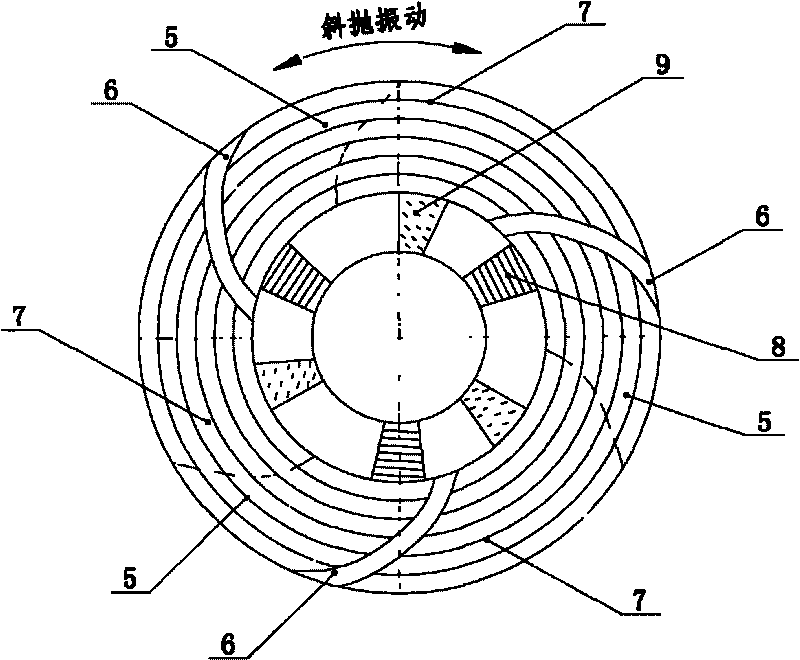

[0013] As shown in the figure: a circular plane vibrating shaker, the whole circular plane shaker is installed on the foundation through the shock absorbing device 3, the bed surface 2 of the vibrating shaker is arranged on the shock absorbing device, and the bed surface is fixed on the central tube 1, A vibrating motor 4 is arranged obliquely below the central tube, and several tailing coal channels 6 are arranged on the bed surface 2, and a clean coal belt 5 and a medium coal belt 7 are also arranged on the bed surface.

[0014] Several feeding areas 8 and water supplying areas 9 are evenly distributed on the bed surface 2, and the materials are fed from the center, and the materials are sorted after the bed surface is vibrated, and the concentrate and tailings are discharged from the tailing coal tank.

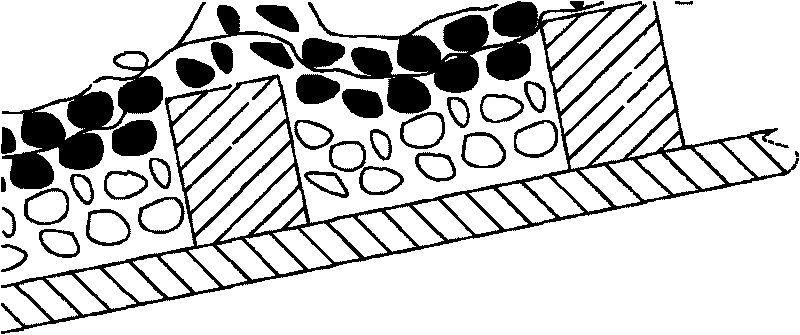

[0015] The bed surface of the vibrating shaking table is composed of a plurality of single bed surfaces, and each bed surface can carry out mineral separation independently....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com