a lifting tool

A technology of hoist and body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

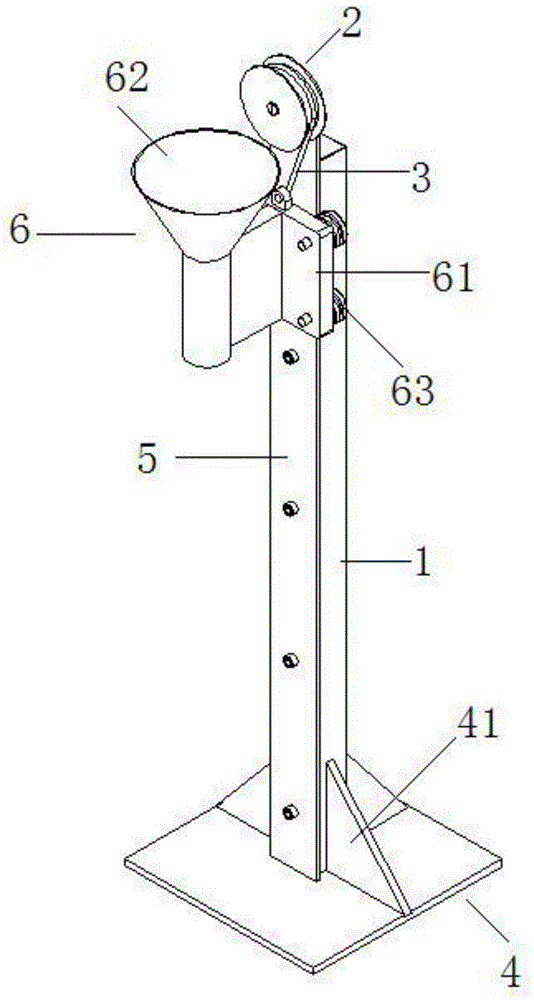

[0020] Embodiment 1: as figure 1 In the shown embodiment, a kind of lifting equipment includes a column 1, a winch 2 that can rotate and lock, and a steel cable 3. A part of the steel cable 3 is wound on the winch 2 and one end of the steel cable 3 is connected to the The winch 2 is fixed, the outer end of the steel cable 3 is outside the winch 2, the column 1 is fixed on the ground through the base 4, the column 1 is provided with a vertical rail 5, and the vertical rail 5 is provided with There is a lifting basket 6 slidingly connected with the vertical rail 5, and the sliding direction is the vertical direction. The lifting basket 6 includes a main body 61 and an outer basket 62, and the winch 2 is directly above the main body 61. The main body 61 is hung by wire rope 3. The body 61 is slidingly matched with the vertical rail 5 through several rollers 63 connected outside the body 61 , and the winch 2 is fixed on the top of the vertical rail 5 . The base 4 is provided wit...

Embodiment 2

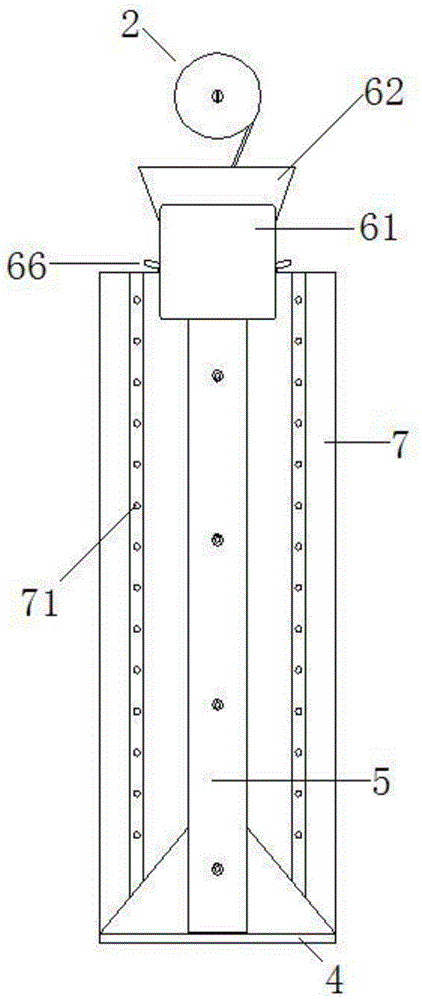

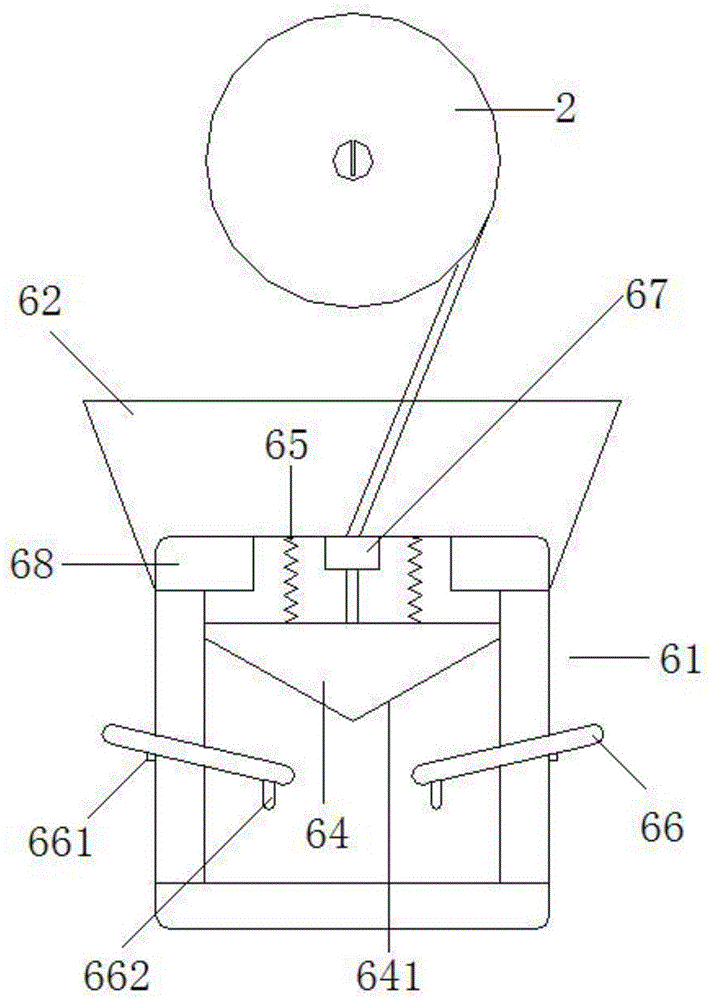

[0022] Embodiment 2: the basic structure and implementation mode of this embodiment are the same as embodiment 1, and its difference is, as figure 2 , image 3 , Figure 4 As shown, the left and right sides of the column 1 are provided with side bases 7, the inside of the body 61 is a cavity, and the outer end of the steel cable 3 passes through the cable hole at the top of the body 61 and extends into the cavity. The outer end of the steel cable 3 is connected to a protective core seat 64, and the protective core seat 64 has at least two push-out surfaces 641, and the top of the protective core seat 64 and the inner top surface of the body 61 are provided with A plurality of protection springs 65, the side of the body 61 is provided with two protection rods 66, the body is provided with two opposite rod holes, one protection rod 66 is correspondingly connected to a rod hole by sliding, the described The angle between the protection rod 66 and the horizontal plane is 15 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com