A front floor assembly spreader

A front floor assembly and spreader technology, which is applied to load hanging elements, lifting devices, hoisting devices, etc., can solve the problems of low utilization rate of robots, potential safety hazards, low efficiency, etc., and achieve simple structure and operation. Convenience and high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

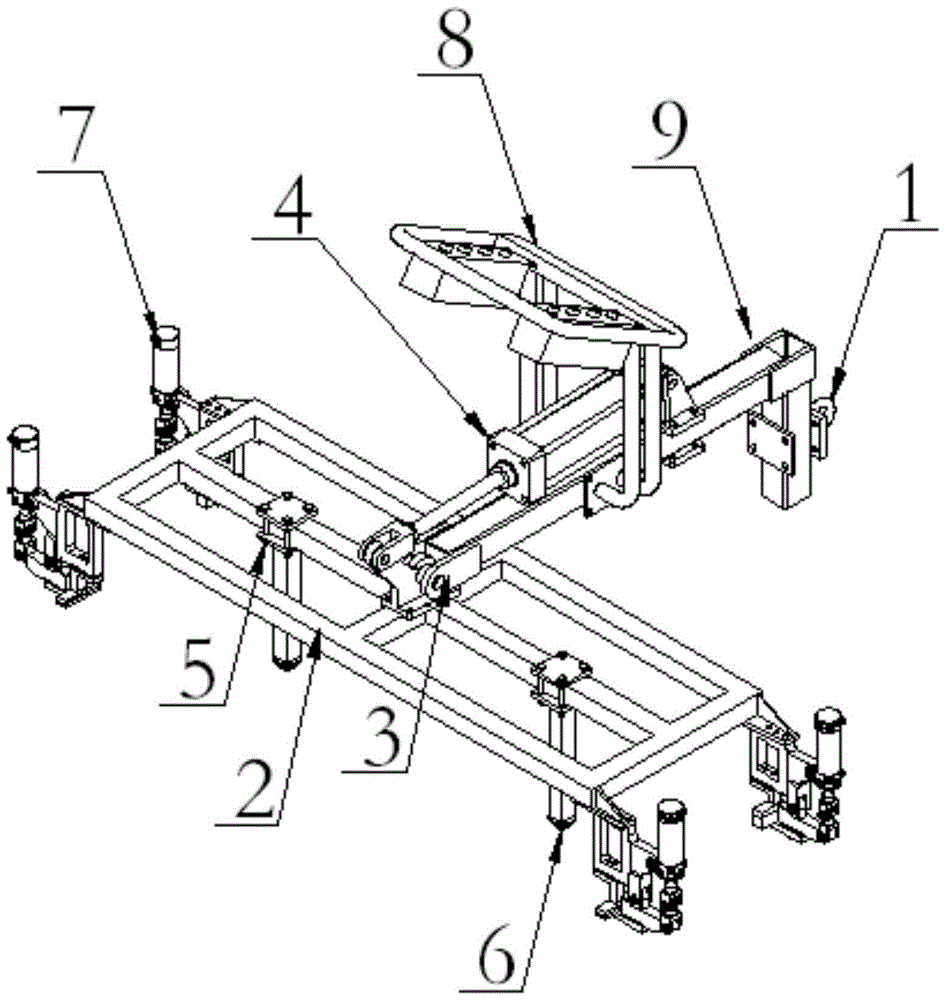

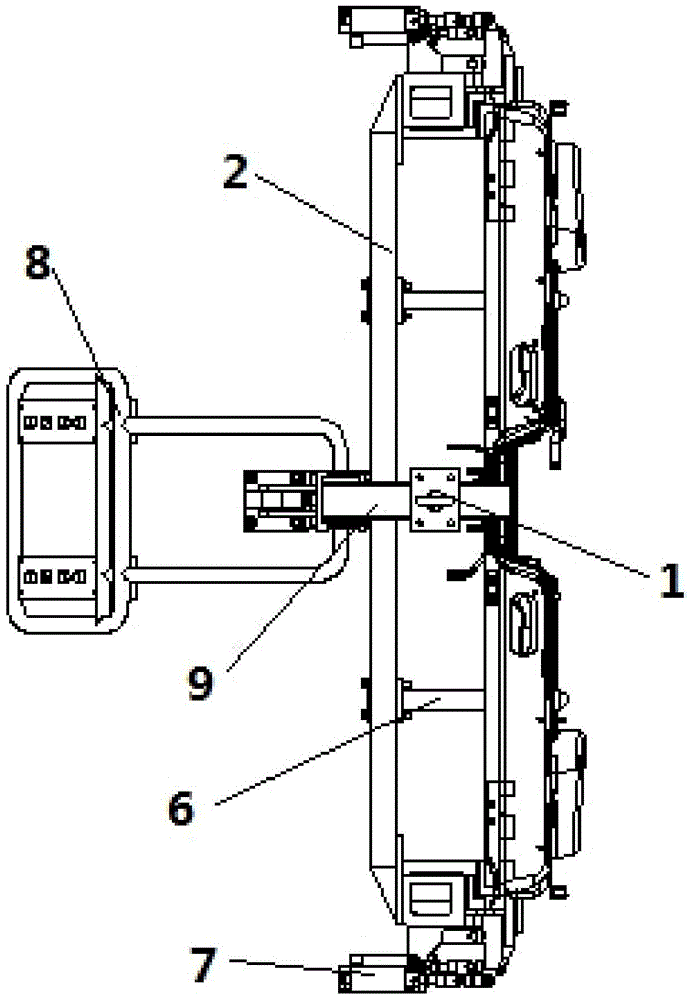

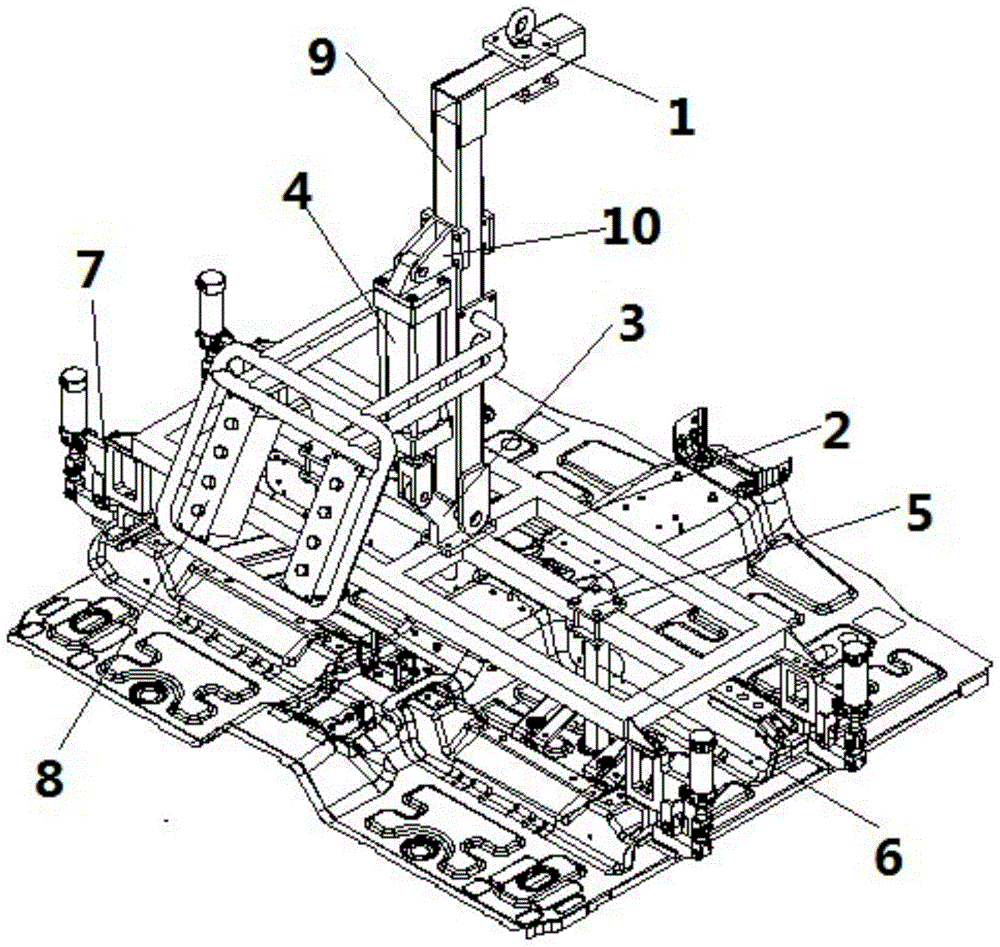

[0021] The front floor assembly hanger of the present invention, such as figure 1 , 2 As shown, it includes a lifting lug 1, a main frame 2, a connecting plate 3, a driving cylinder 4, a positioning pin 6, a clamping mechanism 7, an operation panel 8, and a boom 9. The connecting plate 3 is an obtuse corner seat arranged on the main body frame 2. One end of the two corners of the connecting plate 3 is hinged to drive the cylinder 4, and the other end is hinged to the end of the suspender 9. Clamping mechanism 7 of the front floor assembly.

[0022] The main frame 2 is a rectangular frame structure welded by square steel, and the size of the frame structure is related to the structure size of the front floor assembly. A square steel beam is added in the middle and welded with a rectangular fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com