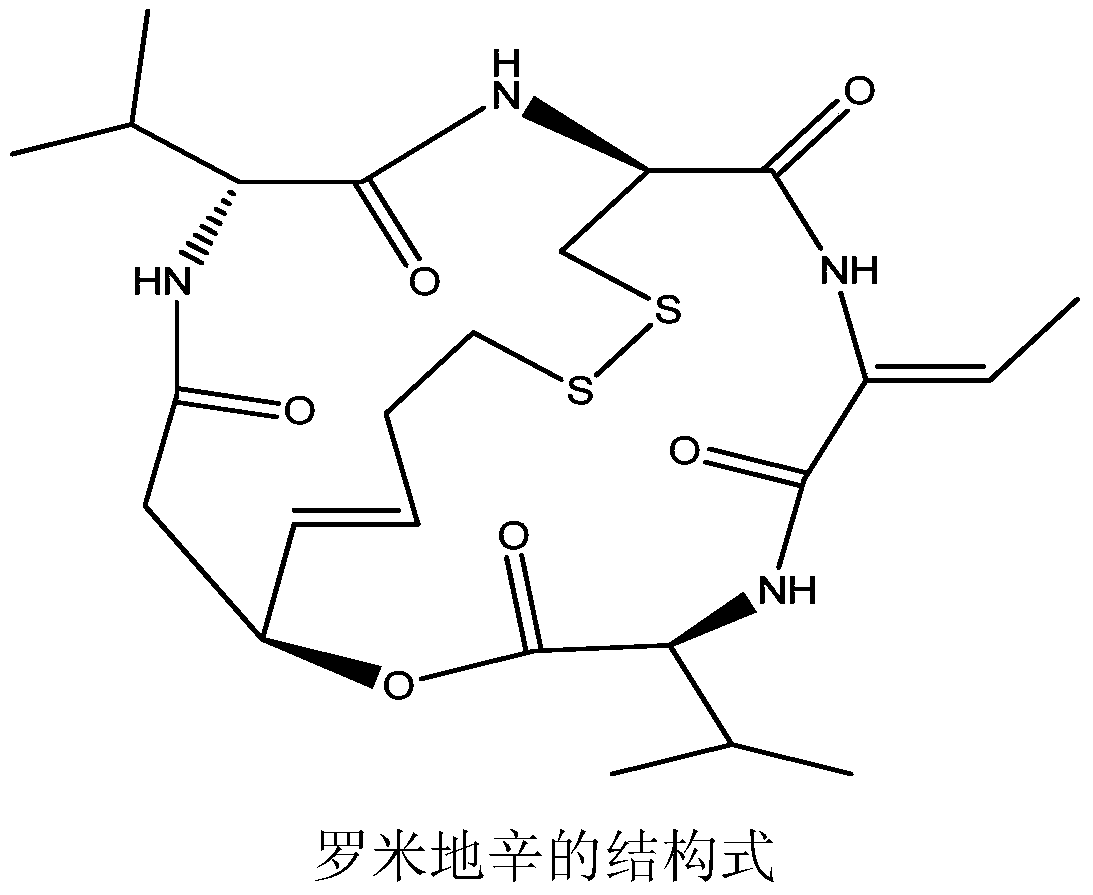

A kind of method and fermentation medium for producing romidepsin

A fermentation medium and technology of romidepsin, applied in the field of romidepsin production, can solve the problem of low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]Chromobacterium violaceum (Chromobacterium violaceum) WB968 was activated and inoculated on the slant medium (LB medium: sterilized at 121°C for 20 minutes), and the slant was placed in a constant temperature incubator at 28°C for 1 day to obtain the bacteria in the growth phase. Then the bacteria were inoculated into a 250mL shaker flask containing 30mL seed medium (glucose 1%, yeast extract 0.5%, peptone 1%, sodium chloride 0.5%), and cultured on a shaker at 30°C and 220rpm for 1 day to obtain mature The seed solution obtained was inserted into 30mL fermentation medium (glucose 2%, mannitol 2%, corn steep liquor 1.0%, casein 0.2%, soybean powder 0.5%, sodium chloride 0.5%, potassium dihydrogen phosphate 1.0%, magnesium sulfate heptahydrate 0.05%, rice oil 0.05%, pH7.0) in a 250mL shake flask, placed in a shaker at 25°C for 96 hours, the relative titer was 300%, The output of romidepsin is 600mg / L.

Embodiment 2

[0036] The method for producing romidepsin in Examples 2-23 is the same as in Example 1, except that the components and / or contents in the fermentation medium are different, and the relative potency and yield are different. Examples 2-23 The content, relative potency and yield of each component in the medium fermentation medium are shown in Table 1. Wherein, the relative potency in Example 2 is 100%. The method for producing romidepsin in Comparative Examples 1-13 is the same as that of Example 1, except that the components and / or contents in the fermentation medium are different, and the relative potency and yield are different. Comparative Examples 1-13 The contents, relative potency and yield of each component in the fermentation medium of 9 are shown in Table 2. Table 3 shows the content, relative potency and yield of each component in the fermentation medium of Comparative Examples 10-13.

[0037] In the following tables 1-3, (1): glucose (%); (2): mannitol (%); (3): co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com