Helical baffle-heat exchanger

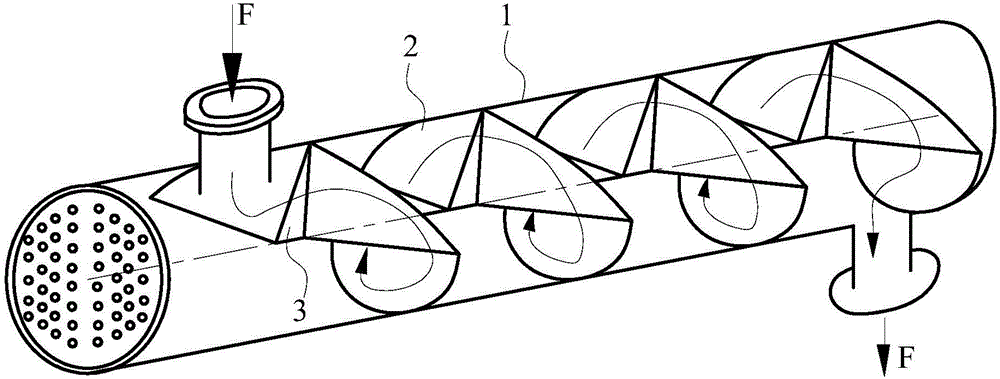

A technology of spiral baffles and heat exchangers, which is applied in the direction of heat exchanger shells, heat exchange equipment, lighting and heating equipment, etc., can solve problems such as leakage, avoid leakage and ensure heat exchange performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following notes are provided in the embodiment of the present invention.

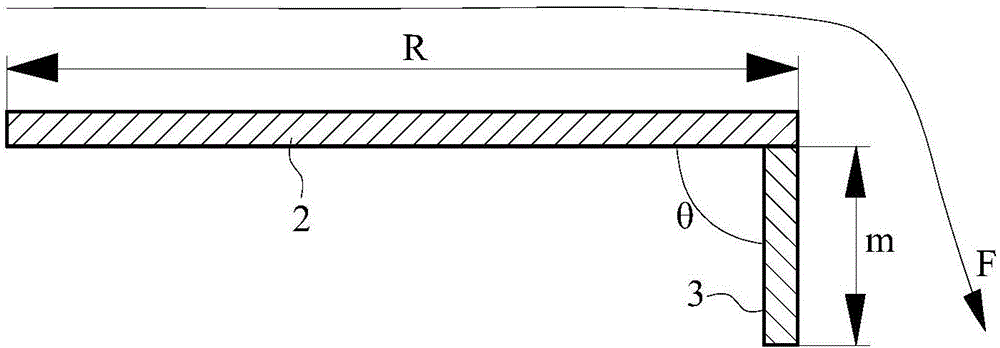

[0032] The inclination angle of the baffle: the angle between the plane of the baffle and the axis of the shell after the baffle rotates along its radius.

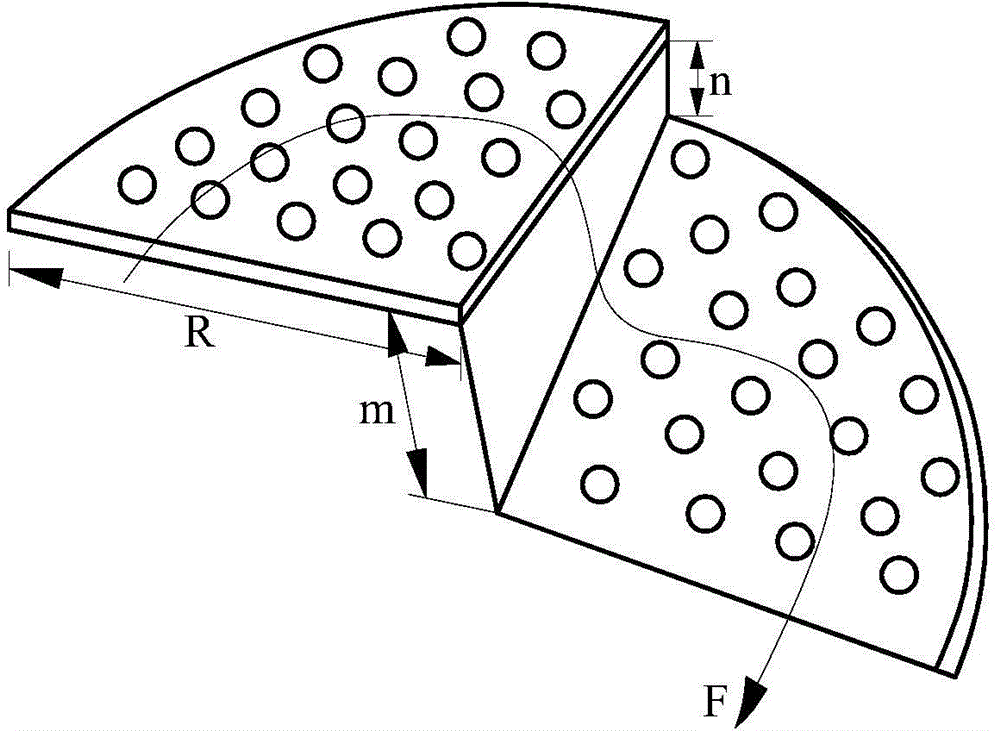

[0033] Inner weir height: the height of the edge of the partition near the center of the fan-shaped baffle;

[0034] Outer weir height: the height of the edge of the partition near the arc edge of the fan-shaped baffle.

[0035] Leakage phenomenon: There is a certain gap between adjacent baffles during the lapping process. In this way, when the fluid in the shell side flows, a part of the fluid will flow regularly along the preset baffle channels, and another part of the fluid will leak into the next area through the modified gap, resulting in the fluid passing through the heat exchange tube As the flow rate decreases, the fluid velocity becomes slower, thereby reducing the heat transfer coefficient of the heat exchanger and affecting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com