A method for measuring pressure drop of magnetic fluid in liquid metal pipeline under strong magnetic field

A liquid metal and measurement method technology, applied in the direction of measuring fluid pressure, pressure difference measurement between multiple valves, measuring devices, etc., can solve the problems of deformation performance and accuracy degradation, long time affects deformation accuracy, etc., and achieve convenient measurement simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

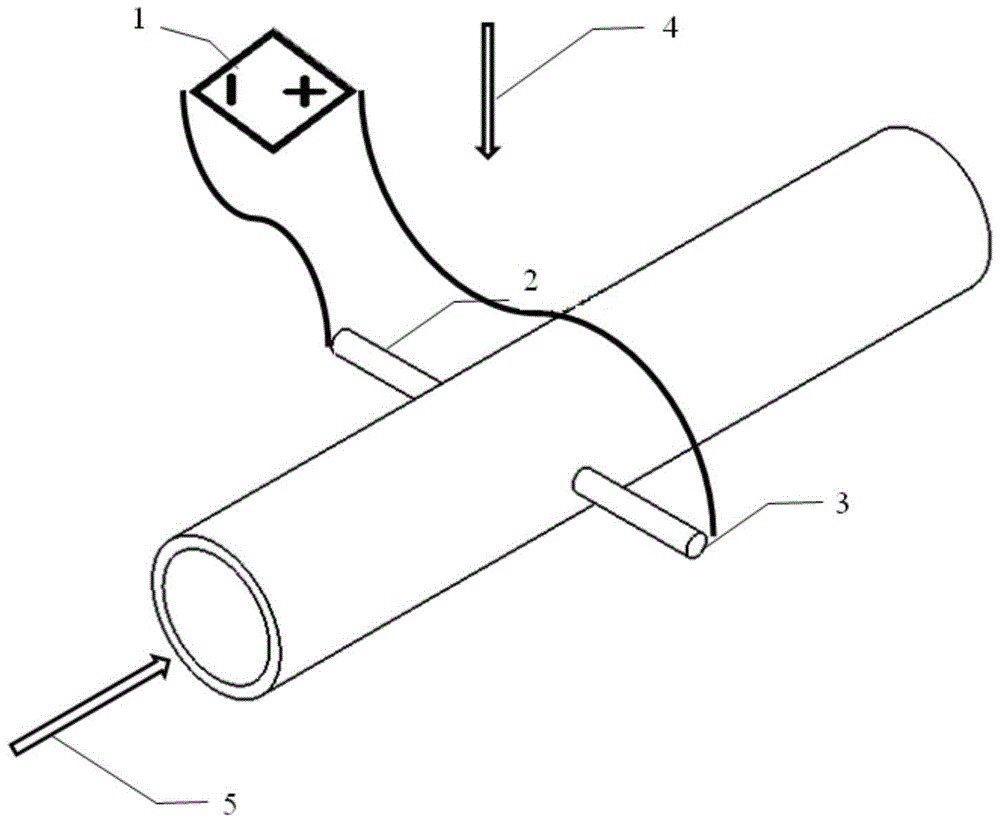

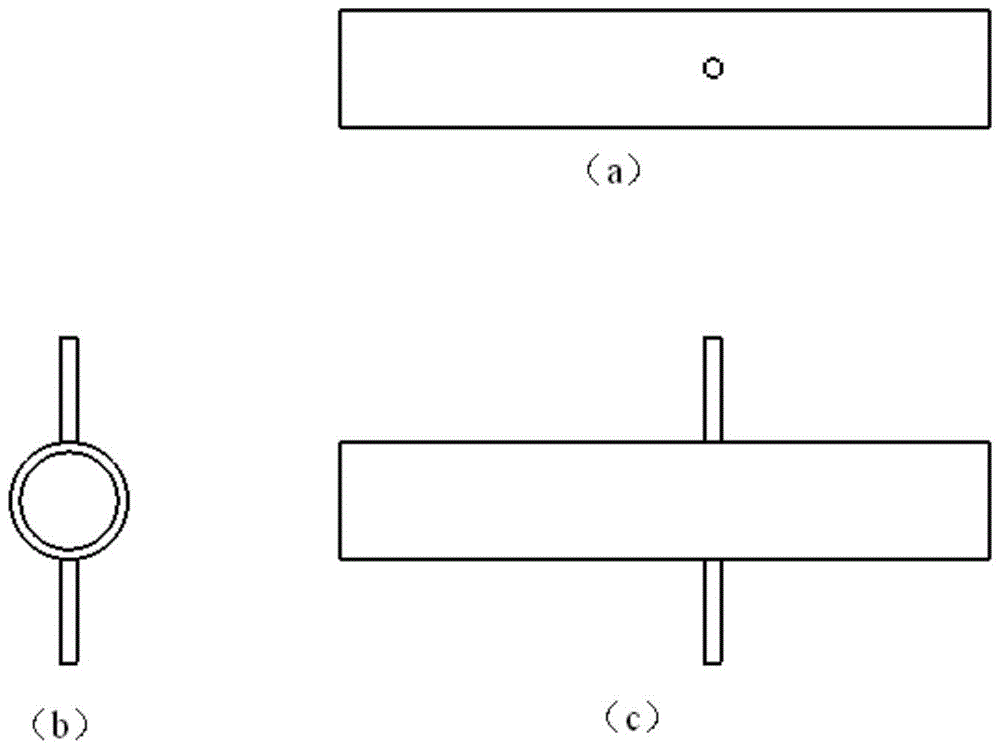

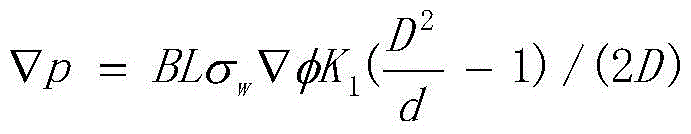

[0029] The invention relates to a method for measuring the pressure drop of liquid metal. The main measurement object is the potential difference on both sides of the pipeline, and the main measurement components include a pair of potential probes, signal lead wires and a high-precision voltmeter. The electrode probes are symmetrically welded on the outer walls of both sides of the metal pipe parallel to the magnetic field, and the material of the probes is the same as that of the pipe, so as to prevent the thermoelectric potential between different materials from interfering with the potential difference signal. The outer end of the probe is connected to the lead wire, and the material of the lead wire is kept the same as that of the probe to avoid thermoelectric potential interference between different materials. The ends of the two lead wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com