Magnetic-sensing-type flow sensing system

A flow sensing and magneto-sensitivity technology, applied in the direction of volume/mass flow generated by electromagnetic effect, volume/mass flow generated by mechanical effect, fluid flow detected by measuring pressure difference, etc., can solve the problem of corrosion resistance of Venturi flowmeter, Poor high temperature resistance, non-adjustable range and other problems, to achieve the effect of low manufacturing cost, simple structure and good system reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

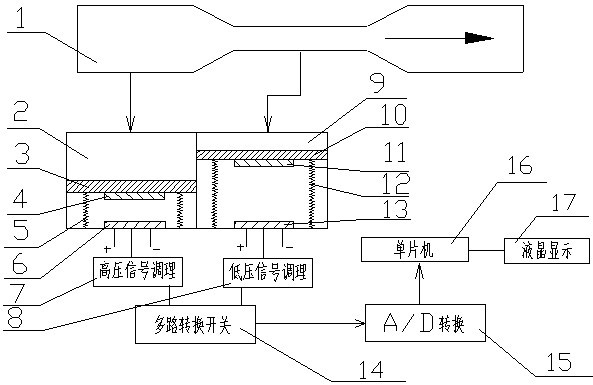

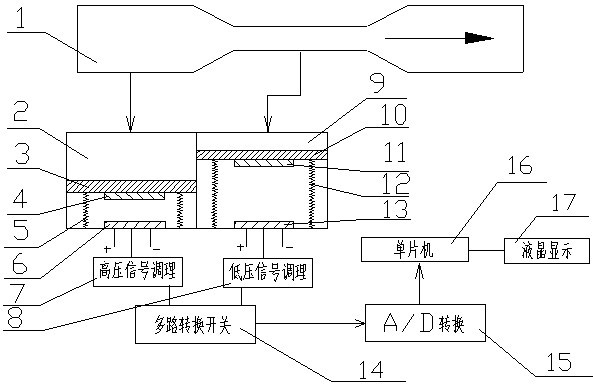

[0017] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0018] Such as figure 1 As shown, the self-magnetic-sensitive flow sensor system of the present invention includes a Venturi tube 1; a high-pressure chamber 2; a high-pressure piston 3; a high-pressure chamber magnet 4; a high-pressure chamber spring 5; a high-pressure chamber magnetic sensor 6; ;Low pressure signal conditioning 8; Low pressure chamber 9; Low pressure piston 10; Low pressure chamber magnetic steel 11; Low pressure chamber spring 12; Low pressure chamber magnetic sensor 13; .

[0019] The fluid flows through the Venturi tube 1, when the liquid in the pipeline flows through the Venturi tube, the section of the liquid flow shrinks, the flow velocity increases at the shrinking section, and the pressure decreases, causing a pressure difference between the front and back of the Venturi tube, and then according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com