Automatic ground pulley collimation device and method

An automatic collimation and pulley technology, which is used in optical fiber/cable installation, cable laying equipment, etc., can solve the problems of inability to carry out on-site inspection, cumbersome wellhead jamming, and no fixed space and position at the wellhead.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

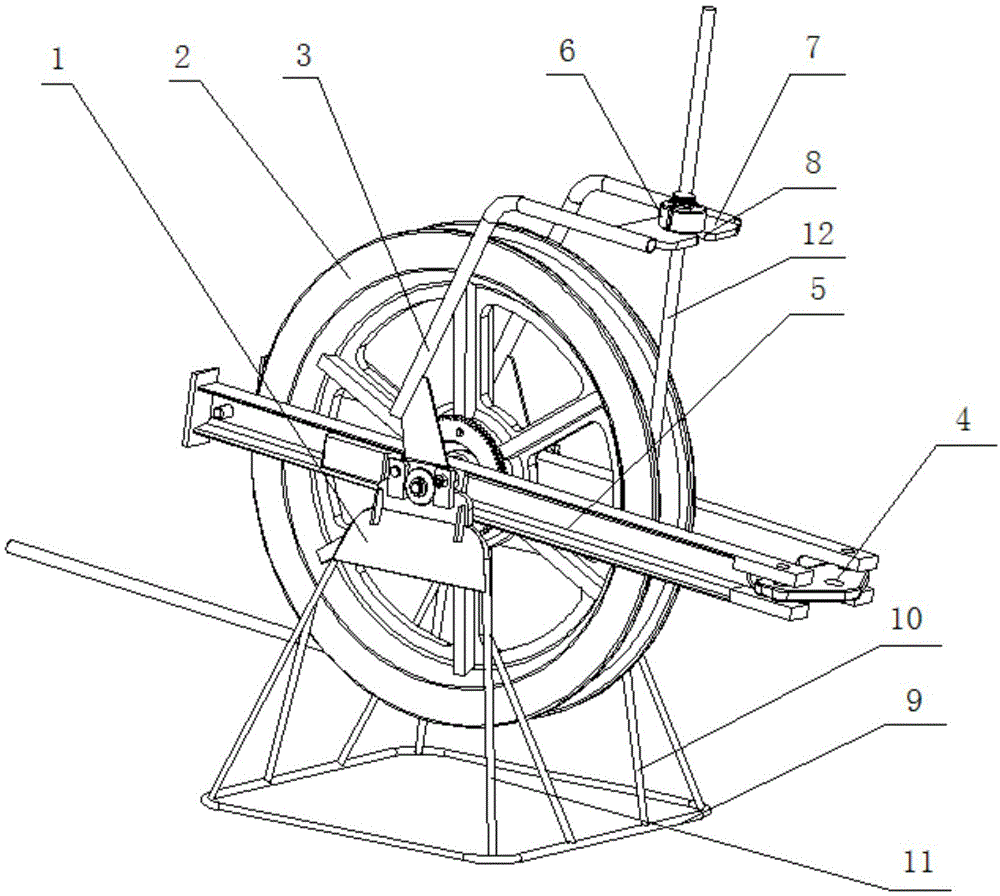

[0020] A ground pulley automatic alignment device, including a balance bracket 1, a ground pulley 2 suspended on the balance bracket 1 through a rotating shaft, and an automatic alignment lever 3, which is symmetrically located on both sides of the ground pulley 2, and the rotating arm One end is installed on the rotating shaft, and the other end has a fairlead, and the ground force point 4 of the ground pulley and the fairlead are located on the same side of the rotating shaft. The upper part of the balance bracket 1 is equipped with an open-close structure 5 through a rotating shaft. The open-close structure 5 is symmetrically installed on both sides of the ground pulley 2, and the two ends are detachably installed by bolts. Pulley 2 does not move horizontally. The fairlead is surrounded by two semicircular structures 6, and the semicircular structures 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com