A mold and method for preparing a porous metal material body

A porous metal and green body technology, applied in the field of material processing and manufacturing, can solve the problems of shortened service life, failure to operate, unstable performance, etc., and achieve the effects of reduced production costs, reasonable mold structure, and complete shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

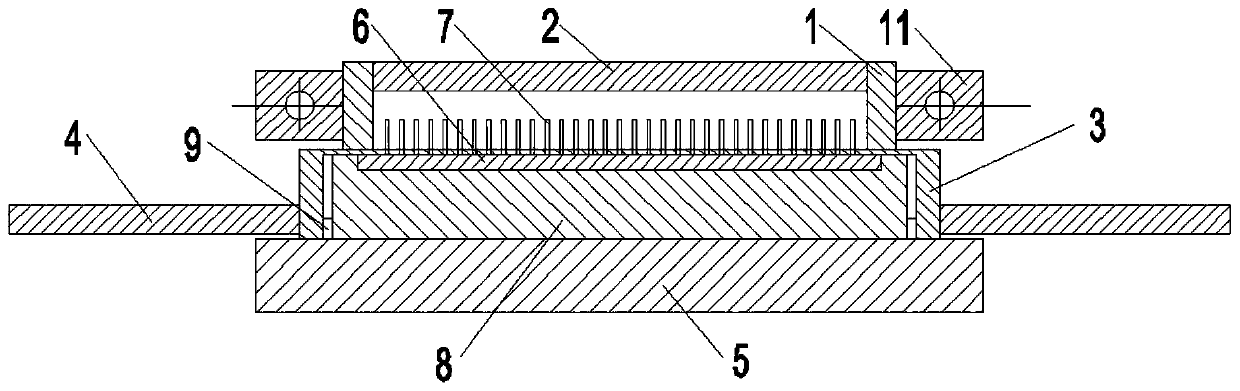

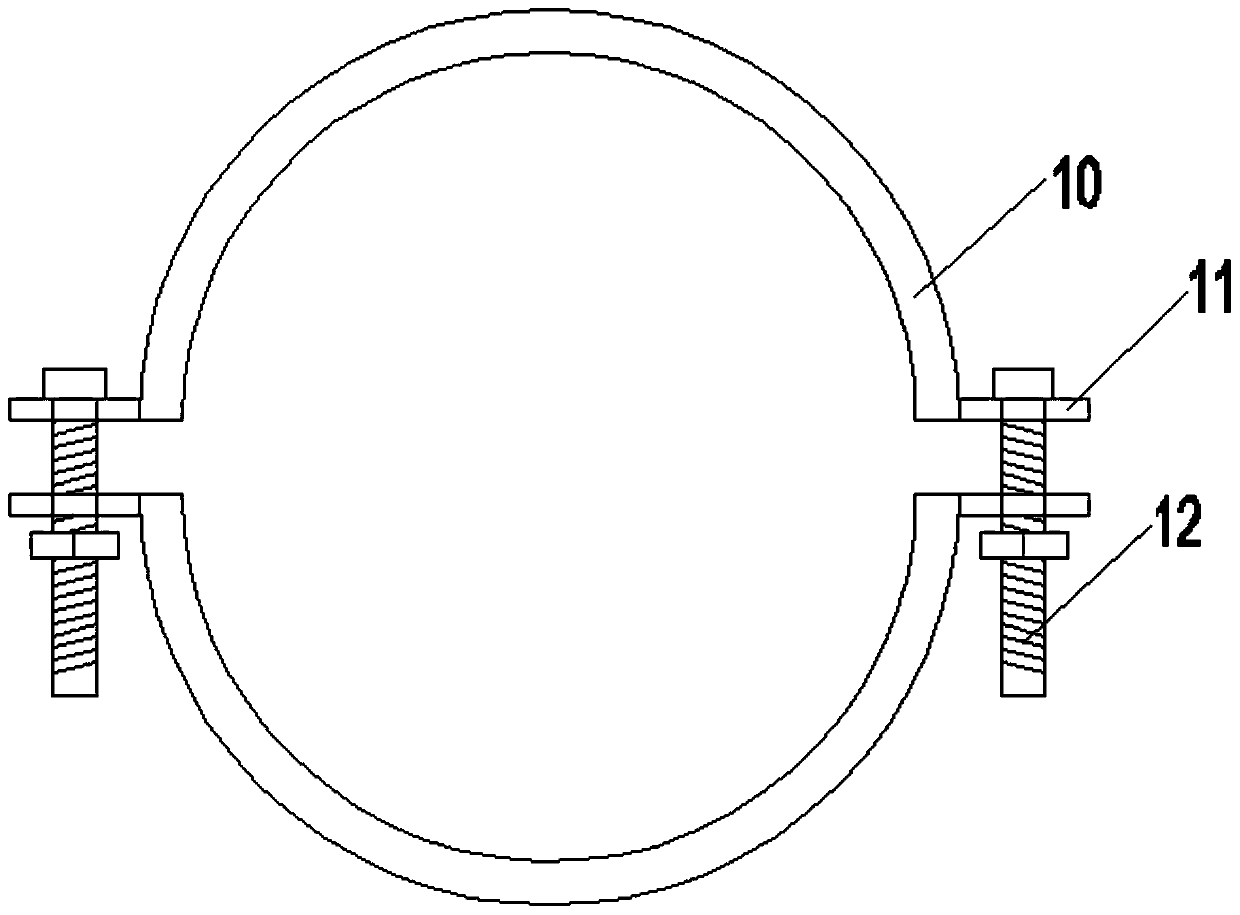

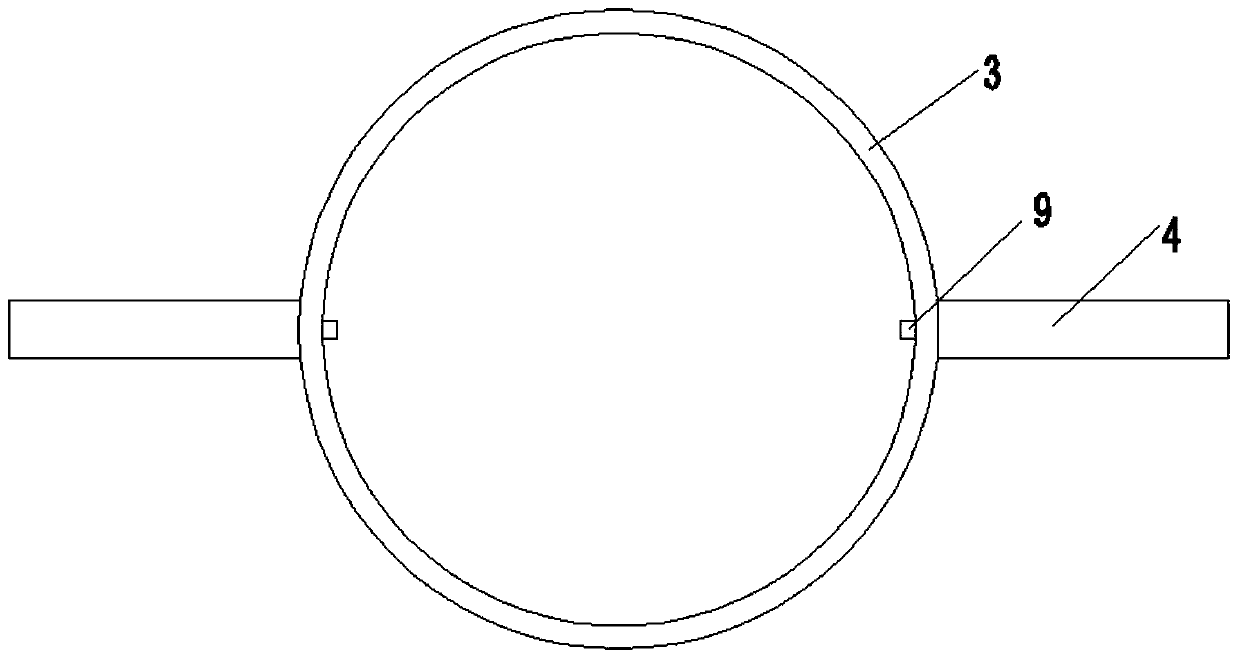

[0027] Such as figure 1 , figure 2 and image 3 A mold for preparing a porous metal material blank is shown, including a base plate 5, a lining plate 8 fixedly arranged on the base plate 5, and a release plate 3 inverted on the lining plate 8, and the top center of the lining plate 8 is A groove is opened at the position, and a needle plate 6 is placed in the groove, and a plurality of mold needles 7 passing through the top of the stripping plate 3 are arranged on the needle plate 6, and the top of the stripping plate 3 is provided with a useful On the female mold 1 loaded with metal powder, the female mold 1 is provided with a female mold pressing plate 2, the outer periphery of the stripping plate 3 is fixedly provided with a handle 4, and the inner side of the stripping plate 3 is provided with a slider 9. The liner 8 is provided with a chute corresponding to the position of the slider 9, and the horizontal cross-section of the die pin 7 is circular, square or hexagonal....

Embodiment 2

[0032] The preparation method of the porous metal material green body in this embodiment includes the following steps:

[0033] Step 1. Evenly pack 350-mesh iron-chromium-aluminum metal powder into the female mold 1 of the mould, and then cover the female mold pressing plate 2;

[0034] Step 2: first use a hydraulic press to compact the iron-chromium-aluminum metal powder in the mold with a pressure of 300 MPa, then slide the stripping plate 3 upwards through the handle 4 to separate the stripping plate 3 from the lining plate 8, and then place the stripping plate 3 Place on the platform for 10 minutes, then open the female mold 1, and finally remove the female mold pressing plate 2 to obtain a porous iron-chromium-aluminum metal body.

[0035] The porous iron-chromium-aluminum metal material body obtained in this example has no cracks, no delamination, and is integral and free of defects. The porous iron-chromium-aluminum metal material body is placed in a sintering furnace a...

Embodiment 3

[0037] The preparation method of the porous metal material green body in this embodiment includes the following steps:

[0038] Step 1. Evenly pack 200-mesh iron-chromium-aluminum metal powder into the female mold 1 of the mould, and then cover the female mold pressing plate 2;

[0039] Step 2: Use a hydraulic press to compact the iron-chromium-aluminum metal powder in the mold with a pressure of 500 MPa, then slide the stripping plate 3 upward through the handle 4 to separate the stripping plate 3 from the liner 8, and then place the stripping plate 3 Place on the platform for 5 minutes, then open the female mold 1, and finally remove the female mold pressing plate 2 to obtain a porous iron-chromium-aluminum metal body.

[0040]The porous iron-chromium-aluminum metal material body obtained in this example has no cracks, no delamination, and is integral and free of defects. The porous iron-chromium-aluminum metal material body is placed in a sintering furnace and heated at a r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com