A gw-35 type knife switch operating mechanism against mis-locking

A GW-35, knife gate operation technology, used in the field of substations, can solve the problems of preventing false locks, unable to lock, easy to rust, damage to the mechanical strength of the vertical tie rod of the knife gate, etc., to achieve improved reliability, less engineering, and less investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

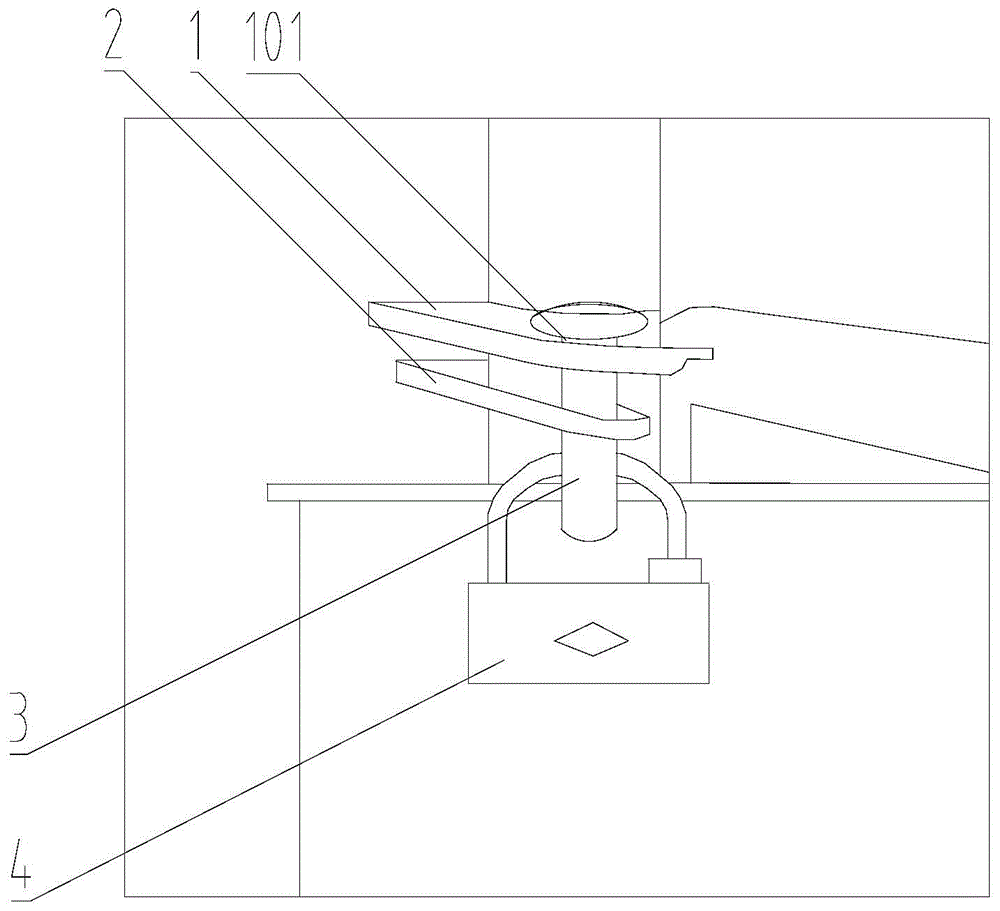

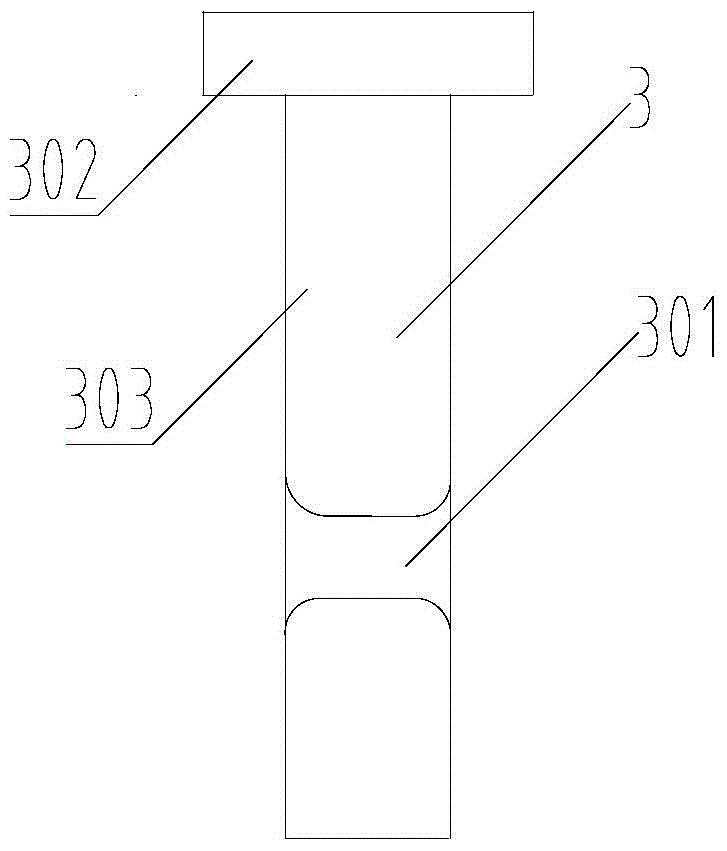

[0021] see figure 1 and figure 2 , an anti-mislocking GW-35 knife gate operating mechanism of the present invention, an operating handle locking hole 101 is provided on the knife valve operating handle 1 along the vertical direction, and one end of the curved pinch plate 2 is fixed on the knife valve operating handle 1 along the horizontal direction. On the valve operating handle 1, the other end of which is suspended in the air, the T-shaped lock pin 3 includes a vertically arranged lock pin upper cover 302 and a pin shaft 303, and a lock pin lock hole 301 is provided in the radial direction of the pin shaft 303, and the T-shaped lock pin 3 The pin shaft 303 passes through the locking hole 101 of the operating handle, and the lower end surface of the upper cover 302 of the locking pin is attached to the operating handle 1 of the knife valve. Knife valve o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com