A pole piece winding method

A pole piece, winding angle technology, applied in electrode manufacturing, electrode rolling/calendering, sustainable manufacturing/processing, etc., can solve the fluctuation of pole piece linear speed, the quality of the cell is prone to powder drop, and the compensation effect is not good. Very good and so on, to achieve good quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The preferred embodiments of the invention will be further described in detail below.

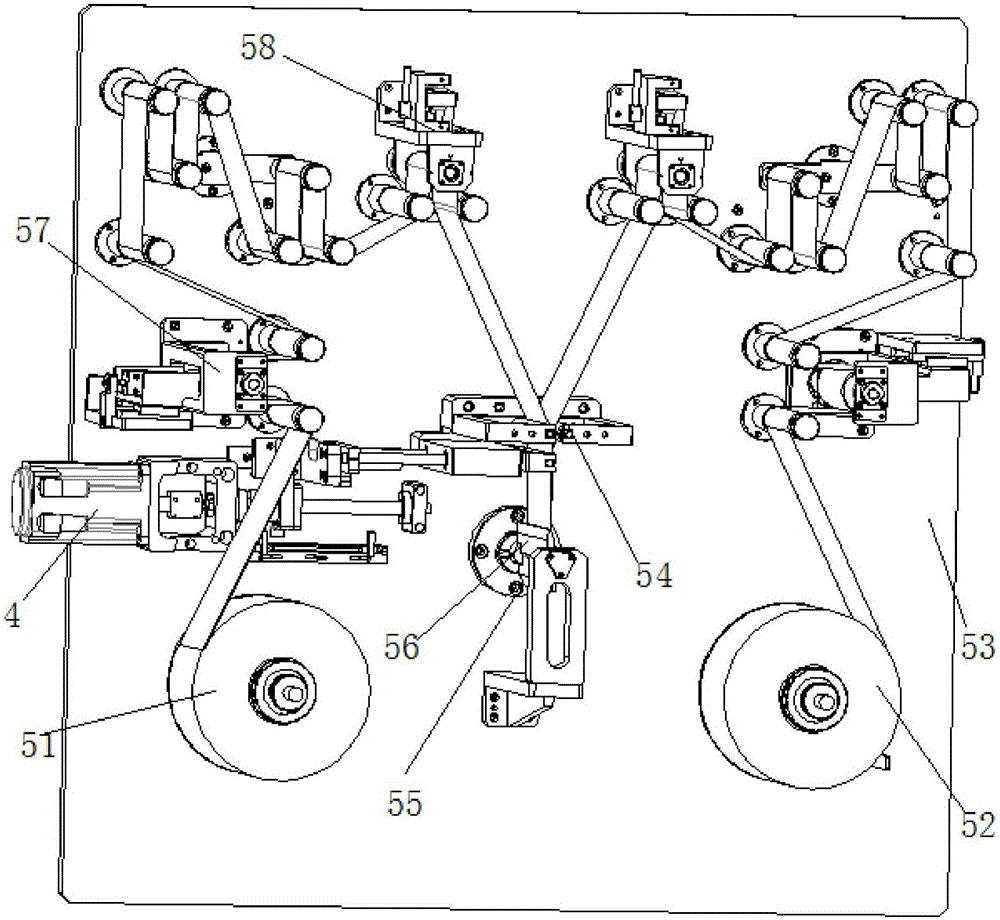

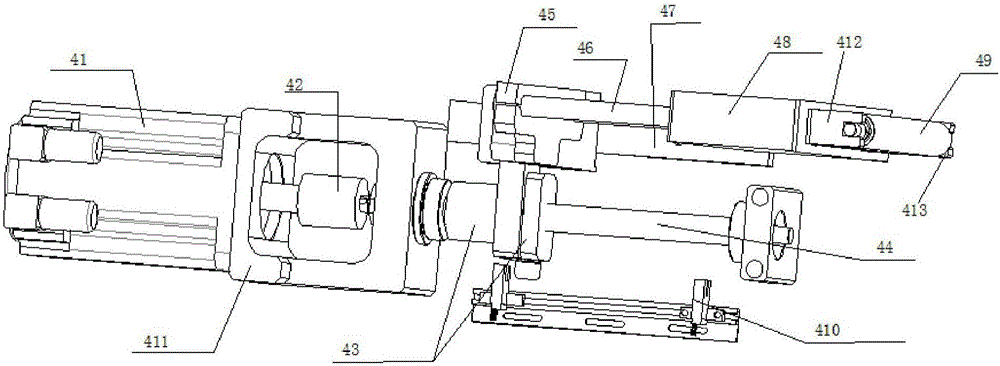

[0047] Such as figure 1 and 2 As shown, a pole piece winding device of an embodiment includes a pole piece unwinding assembly 51 or 52, a pole piece winding assembly 55, and a horizontal electronic cam assembly 4, and the horizontal electronic cam assembly 4 includes a servo motor 41, a joint Shaft device 42, screw nut 43, screw mandrel 44, connecting block 45, guide rod 46, guide rod holder 48 and horizontal pole piece roller 49, the output end of described servo motor 41 is connected with the described shaft coupling 42 The screw rod 44 is connected, the screw nut 43 is sleeved on the screw rod 44, the connecting block 45 is fixed to the screw nut 43, and the connecting block 45 is fixed to one end of the guide rod 46. , the guide rod 46 passes through the guide rod fixing seat 48, the guide rod 46 can slide along the guide rod fixing seat 48, the horizontal pole piece roller 49 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com