Electrodynamic Actuator

An electric actuator and actuator technology, which is applied to electric components, electromechanical devices, electrical components, etc., can solve the problem of not setting a return element, and achieve the effects of small overall size, high cost performance, and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

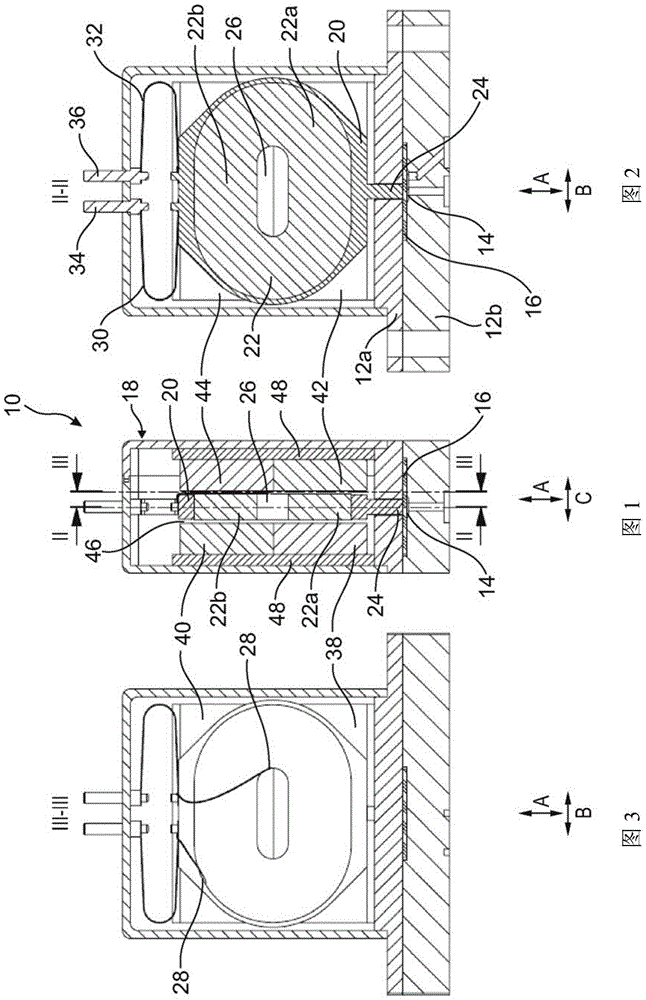

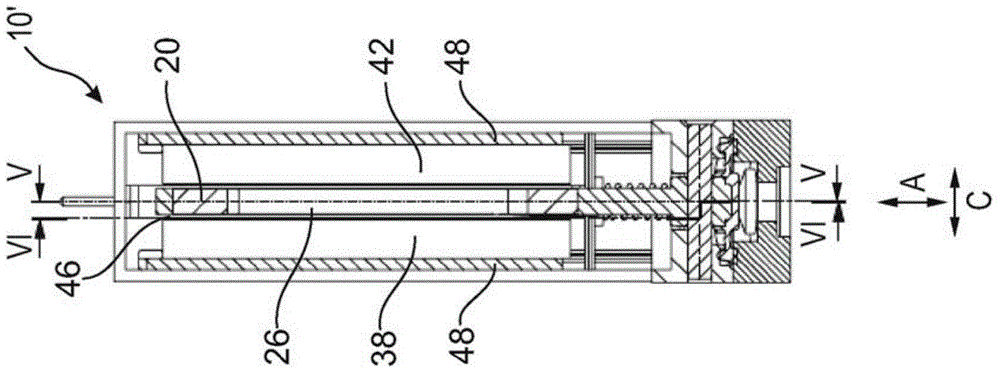

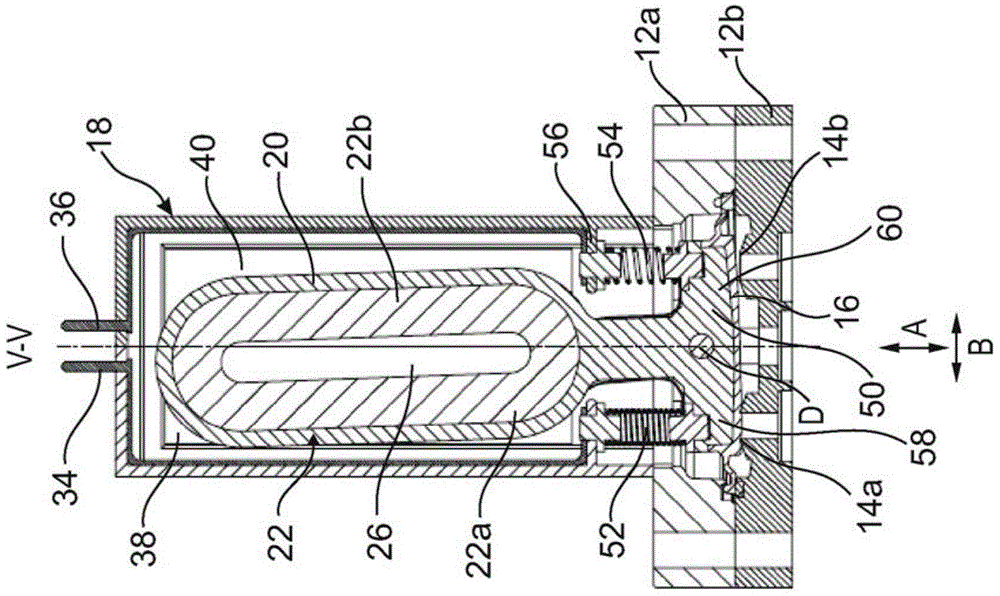

[0088] Figure 1 to Figure 3 A first embodiment of a microvalve 10 with an electric actuator is shown. The electric actuator is mounted on the two-part fluid housings 12a, 12b, and the valve seat 14 is formed in the two-part fluid housings 12a, 12b. A diaphragm 16 clamped between the housing halves 12a and 12b is able to open or close the valve seat 14 by means of an electric actuator.

[0089] The electric actuator includes an actuator housing 18 in which the movable control element and immovable magnet arrangement are housed. The control element is mainly formed by a coil carrier 20 made of non-magnetic material and an air-core coil 22 arranged on the coil carrier 20 . The coil carrier 20 is engaged around the air core coil 22 and mounted so as to be linearly movable in the direction A. As shown in FIG. The extension 24 of the coil carrier 20 protrudes into the recess of the upper half 12 a of the fluid housing and cooperates with the partition 16 .

[0090] The air-core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com