Stepping motor and timepiece provided with stepping motor

A technology of stepping motors and rotors, which is applied in clocks, electromechanical clocks, instruments, etc., can solve problems such as difficulty in miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

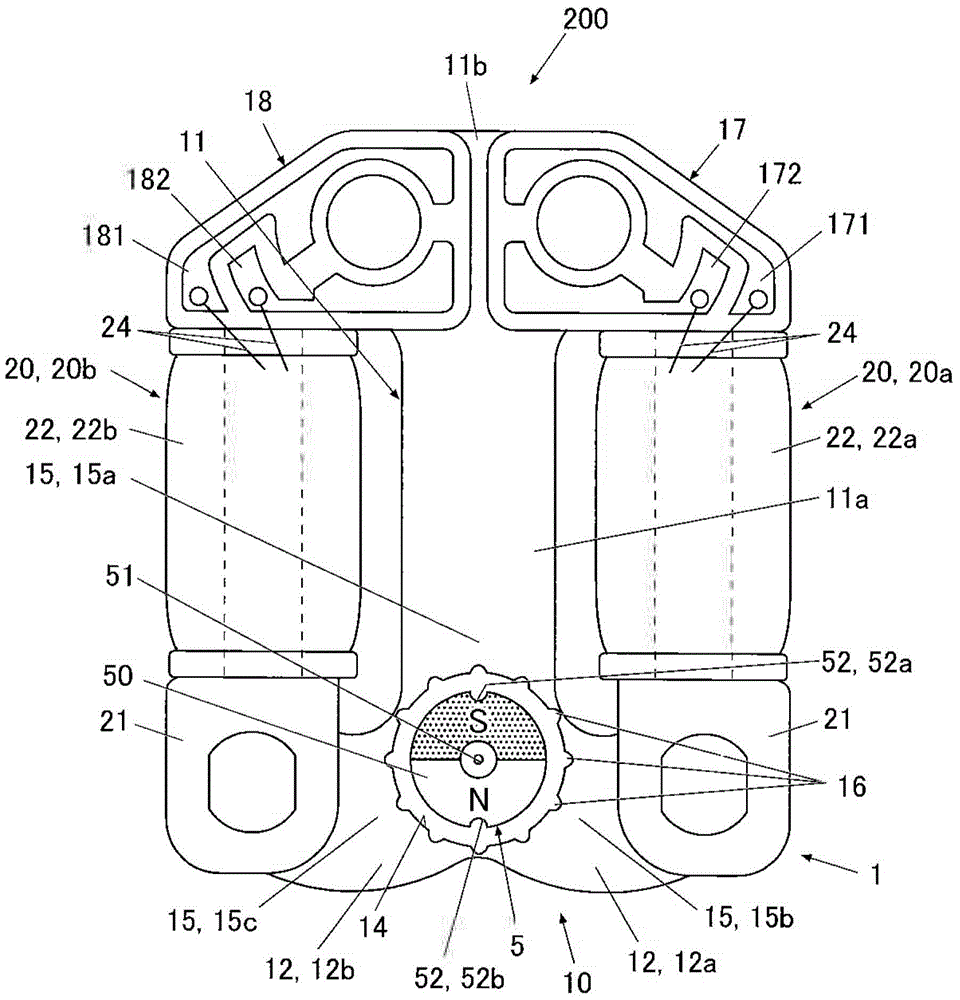

[0042] Below, refer to figure 1 Moving to FIG. 9 , a first embodiment of the stepping motor of the present invention will be described.

[0043] The stepping motor of this embodiment is a small motor used to drive, for example, a hand movement mechanism and a date mechanism for moving the hands of a watch, but embodiments to which the stepping motor of the present invention can be applied are not limited thereto.

[0044] figure 1 It is a plan view of the stepping motor in this embodiment.

[0045] Such as figure 1 As shown, the stepping motor 200 includes a stator 1 (Stator) and a rotor 5 (Rotor).

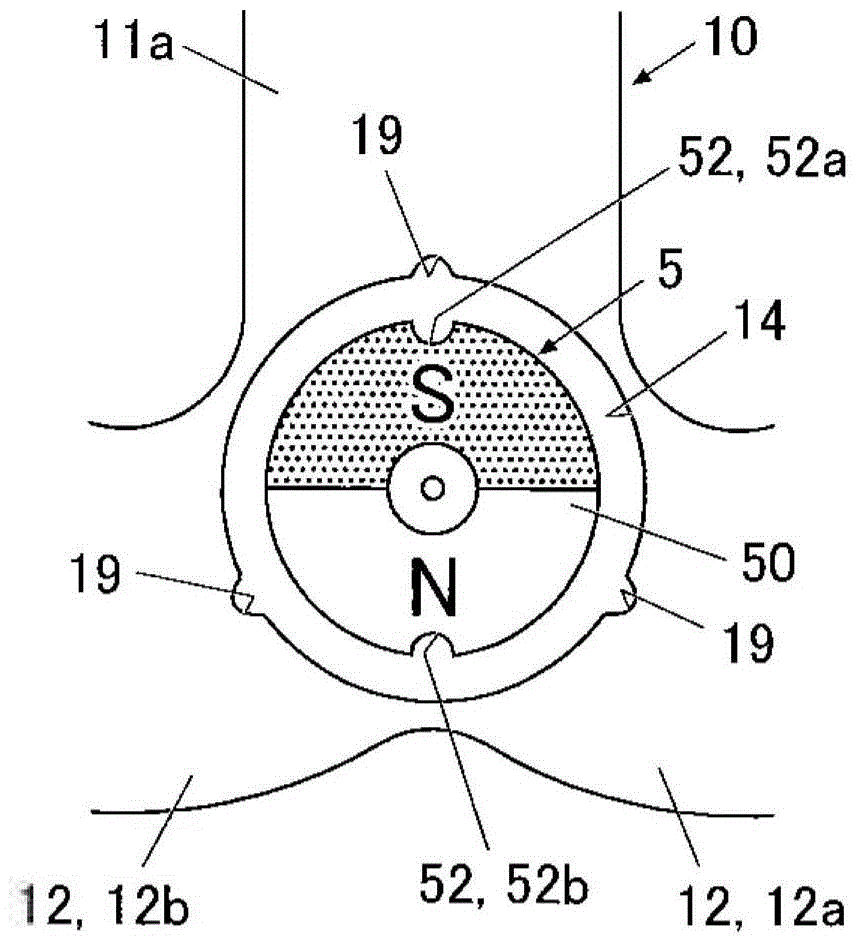

[0046] The rotor 5 has a structure in which a rotor magnet 50 magnetized at two poles in the radial direction is attached to a rotation support shaft 51 .

[0047] In this embodiment, the rotor magnet 50 is formed in a substantially cylindrical shape, and the rotation support shaft 51 is attached to the center of the rotor magnet 50 .

[0048] As the rotor magnet 50 , for exa...

no. 2 approach

[0158] Below, refer to Figure 10 , Figure 11A ~ Figure 11D , Figure 12A ~ Figure 12D , Figure 13A ~ Figure 13D , the second embodiment of the stepping motor of the present invention will be described.

[0159] In addition, since the present embodiment differs from the first embodiment in the manner of applying a drive pulse by the drive pulse supply circuit 31 , the differences from the first embodiment in particular will be described below.

[0160] Figure 10 The timing of application of the driving pulse by the driving pulse supply circuit 31 in this embodiment and the application mode (mode) of the driving pulse in each driving pulse application interval are shown.

[0161] like Figure 10 As shown, the drive pulse supply circuit 31 can appropriately change the pulse width applied in each drive pulse application period, and select an application mode (mode) to apply a drive pulse to only one coil 22 in all drive pulse application periods.

[0162] In this manner,...

no. 3 approach

[0200] Next, refer to Figure 14 , Figure 15A ~ Figure 15D , Figure 16A ~ Figure 16D , Figure 17A ~ Figure 17D , the third embodiment of the stepping motor of the present invention will be described.

[0201]In addition, this embodiment differs from the first embodiment and the like in the application method of the drive pulse by the drive pulse supply circuit 31 , and the difference from the first embodiment and the like will be described below in particular.

[0202] Figure 14 The timing of application of the driving pulse by the driving pulse supply circuit 31 in this embodiment and the application mode (mode) of the driving pulse in each driving pulse application interval are shown.

[0203] like Figure 14 As shown, the drive pulse supply circuit 31 can appropriately change the pulse width applied in each drive pulse application period, and select an application mode (mode) for applying a drive pulse to both coils 22 in all drive pulse application periods.

[02...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com