A powder microwave heating device and its application method

A microwave heating device, heating device technology, applied in the direction of microwave heating, etc., can solve the problems of high price, increase the total power of heating equipment, and accelerate the aging of magnetron, and achieve the effect of uniform heating and elimination of cold spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

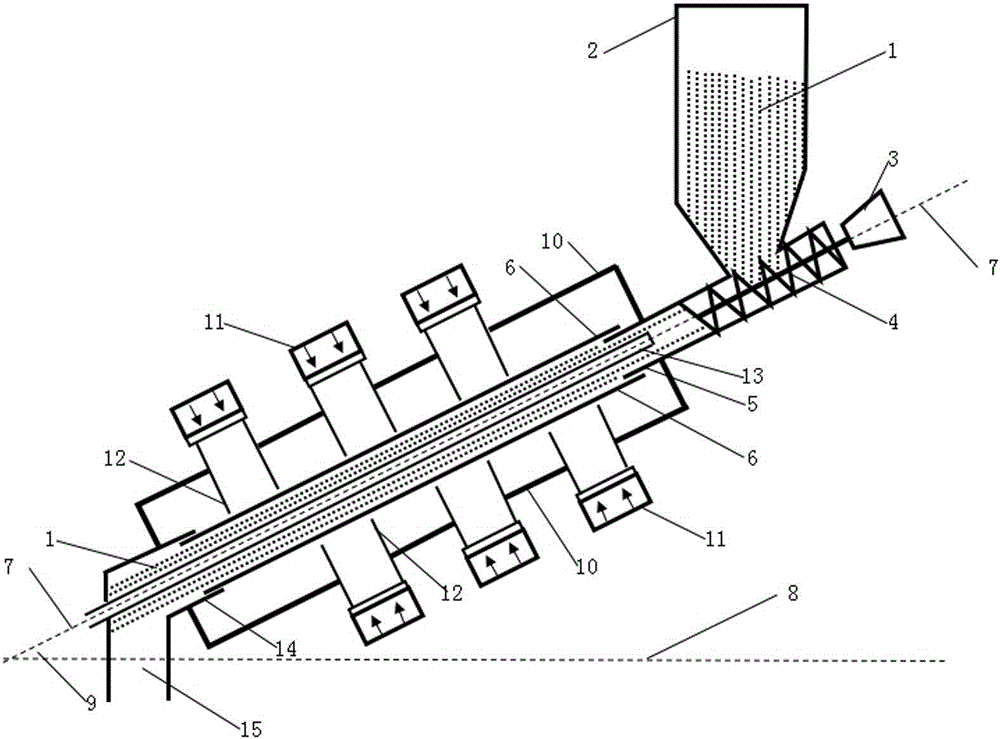

[0050] See figure 1 , crushed to <100 micron powder 1 into the mineral powder silo 2 for standby, control the speed of the motor 3 to make the screw push rod 4 rotate at 50 rpm, and the screw push rod 4 rotates to push the powder 1 through the forming cone sleeve 5 into the inner The equipment inclination angle 9 formed by the centerline 7 of the tube 6 and the heating device and the horizontal plane 8 is close to and not greater than the self-flow angle of the powder 1, and the powder 1 in the inner tube 6 is in a critical state of self-flow; the heating device installed on the outer wall of the outer tube 10 The microwave source 11 divides the inner tube 6 and the outer tube 10 of the heating chamber into six heating sections. Three 1.5KW magnetrons are installed on each heating section, with a total power of 27KW. The opening of the waveguide 12 is close to the outer wall of the inner tube 6 Turn on the power supply of the heating microwave source 11, the microwave that the...

Embodiment 2

[0052] See figure 1 , crushed to <100 micron powder 1 into the mineral powder bin 2 for standby, control the speed of motor 3 to make the screw push rod 4 rotate at 80 rpm, and the screw push rod 4 rotates to push the powder 1 through the forming cone sleeve 5 into the inner The equipment inclination angle 9 formed by the centerline 7 of the tube 6 and the heating device and the horizontal plane 8 is close to and not greater than the self-flow angle of the powder 1, and the powder 1 in the inner tube 6 is in a critical state of self-flow; the heating device installed on the outer wall of the outer tube 10 The microwave source 11 divides the inner tube 6 and the outer tube 10 of the heating chamber into 10 heating sections, and each heating section is equipped with three 1.5KW magnetrons with a total power of 45KW. The opening of the waveguide 12 is close to the outer wall of the inner tube 6 Turn on the power supply of the heating microwave source 11, the microwave that the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com