Device for handling plate-shaped objects

A technology of equipment and objects, which is applied in the field of equipment for operating plate-shaped objects, to achieve the effect of simplifying the structure of mechanical devices and component layout and good accessibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

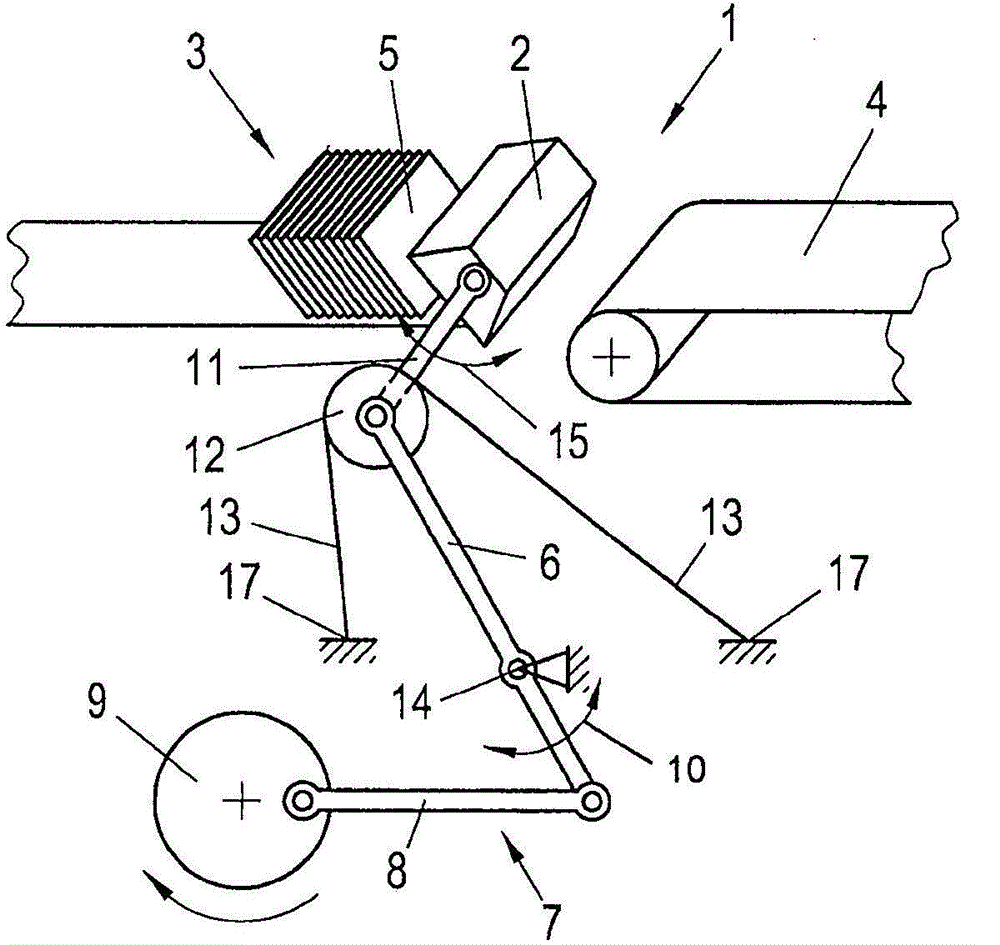

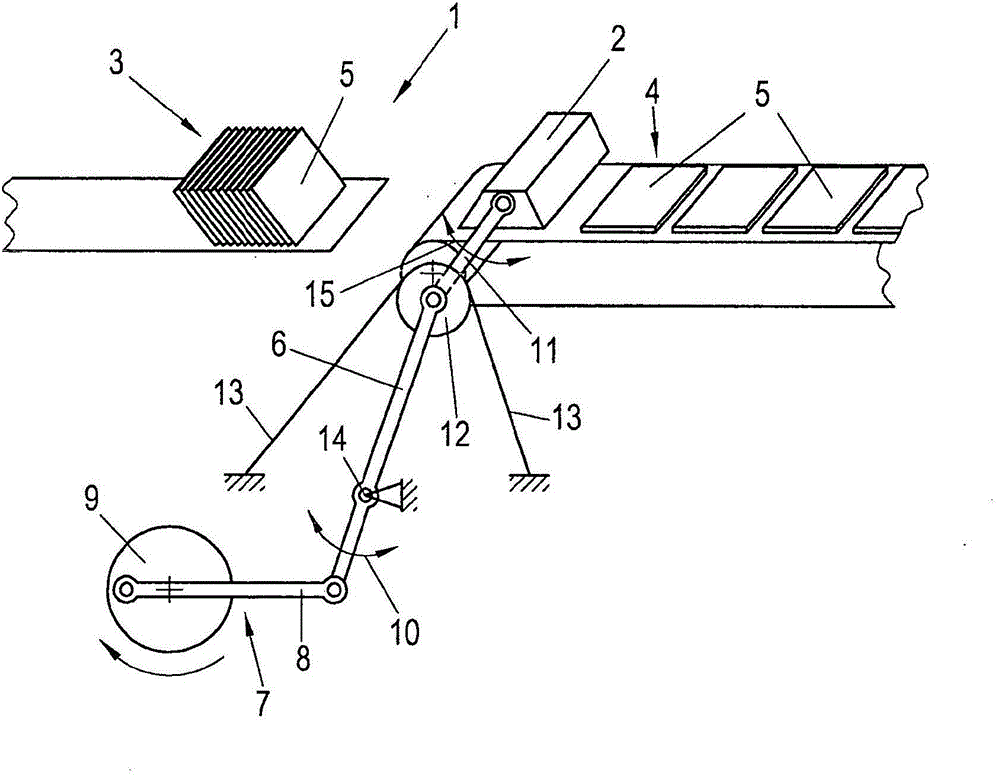

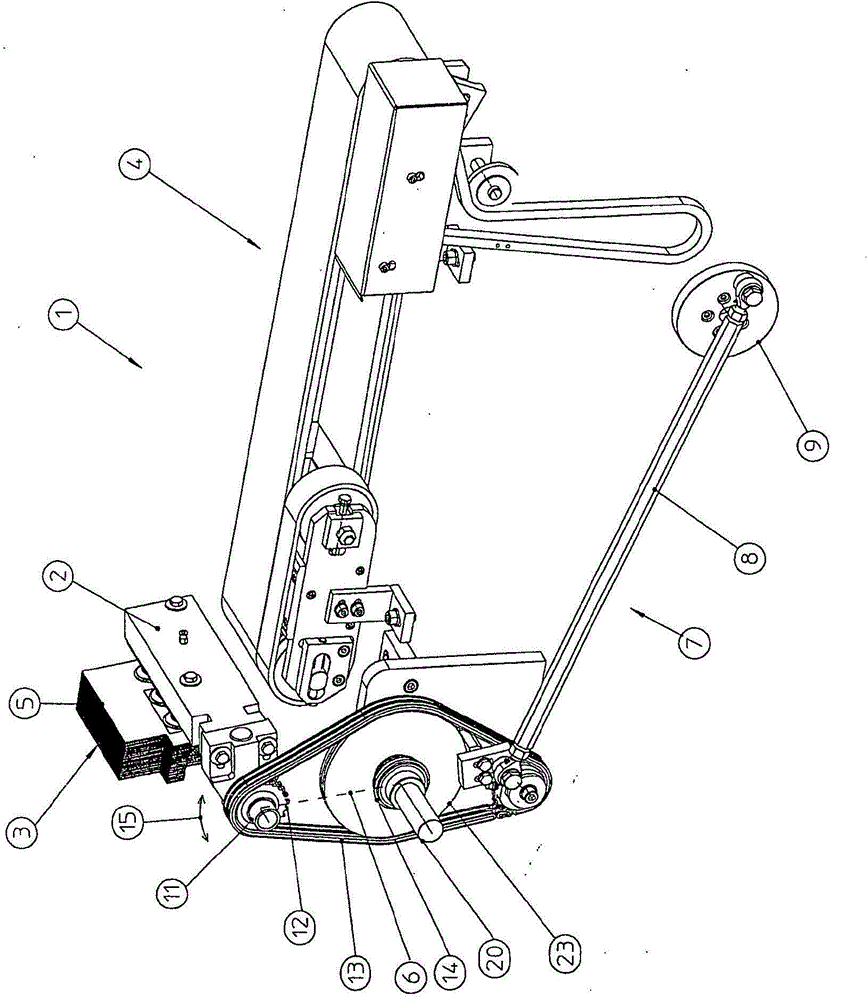

[0031] exist figure 1 and 2 The device 1 for handling objects 5 , in particular for removing panels from stacks 3 , shown schematically in FIG. The extraction position of the front end ( figure 1 ) and the delivery position ( figure 2 ) can move back and forth between.

[0032] The removal gripper 2 is equipped with suction cups 30 which are subjected to a negative pressure in order to receive plate-shaped objects 5 , such as battery panels, from the stack 3 and grip them during transfer to the delivery-side end of the conveyor belt 4 . When removing gripper 2 in accordance with figure 2 When in the position (delivery position), the negative pressure applied to the suction cups 30 is removed, so that the plate-shaped objects 5 are released and placed on the conveyor belt 4 .

[0033] In order to be able to implement in the extraction position ( figure 1 ) and delivery location ( figure 2 ), the removal gripper 2 is set to a lever 6 which can pivot back and forth in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com