A breeding wastewater slag liquid separator capable of automatically cleaning the filter screen

A technology of aquaculture wastewater and automatic cleaning, applied in the direction of filtration separation, separation method, filtration loop, etc., can solve the problems of low cleaning efficiency and poor effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

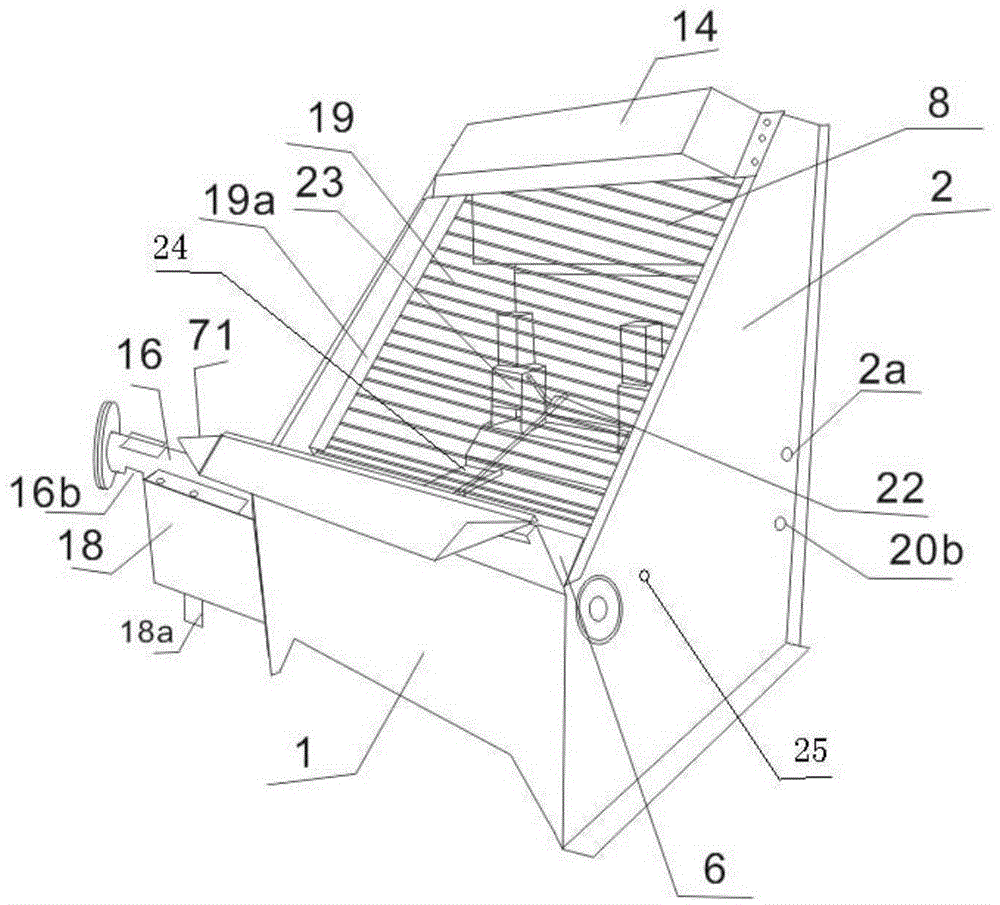

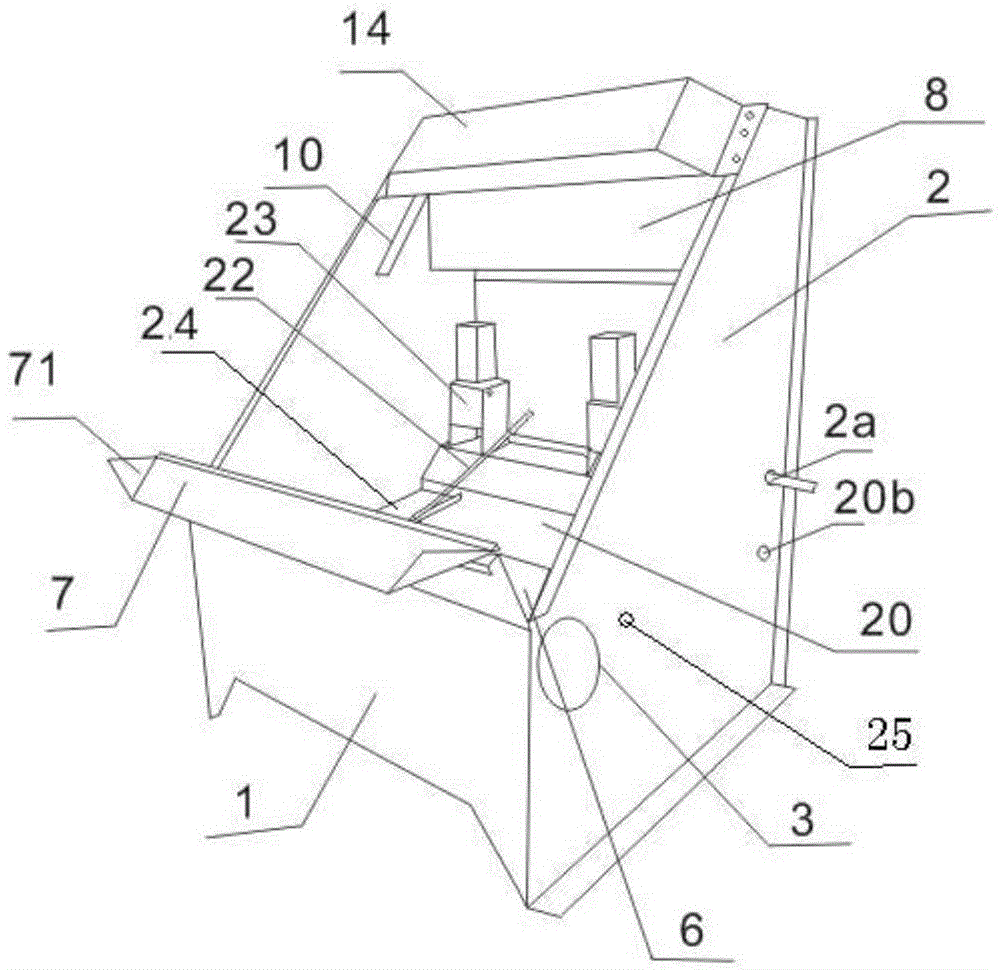

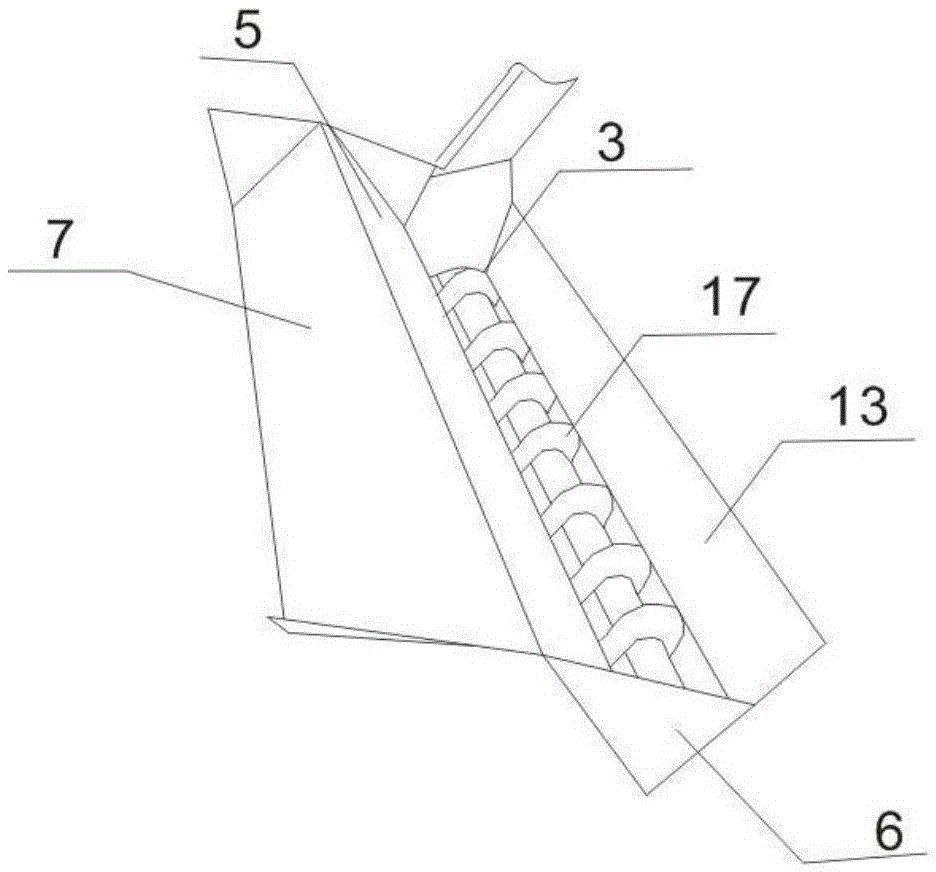

[0046] Such as Figure 1-13 Shown: the aquaculture wastewater slag liquid separator capable of automatically cleaning the filter screen of the present invention consists of a lower box 1, a right-angled trapezoidal plate 2, a screw extruder sleeve mounting hole 3, a water outlet 4, a front baffle 5, and side baffles 6. Cover plate 7, waste water buffer tank 8, waste water inlet 9, filter screen placement plate 10, angle steel 11, waste water baffle plate 12, rear baffle plate 13, upper cover plate 14, front side door plate, rear door plate 15, auger set Tube 16, screw auger 17, waste water collection box 18, filter screen 19, cleaning water tank 20, water pump mounting bracket 21, high-pressure water gun 22 and water gun swinging device 23 and other components.

[0047] The lower ends of the left and right side panels of the lower box 1 extend downwards, and the lower ends of the extensions are bent outwards, and the extensions and the bent portions form the installation porti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com