A series dust collector

A dust collector and series technology, applied to chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve the problems of wasting labor, low applicability of dust collectors, and increased economic costs, so as to reduce manual labor The effect of using, saving economic expenditure, and increasing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the utility model and in conjunction with the accompanying drawings, the technical solution of the utility model is further described, but the utility model is not limited to these embodiments.

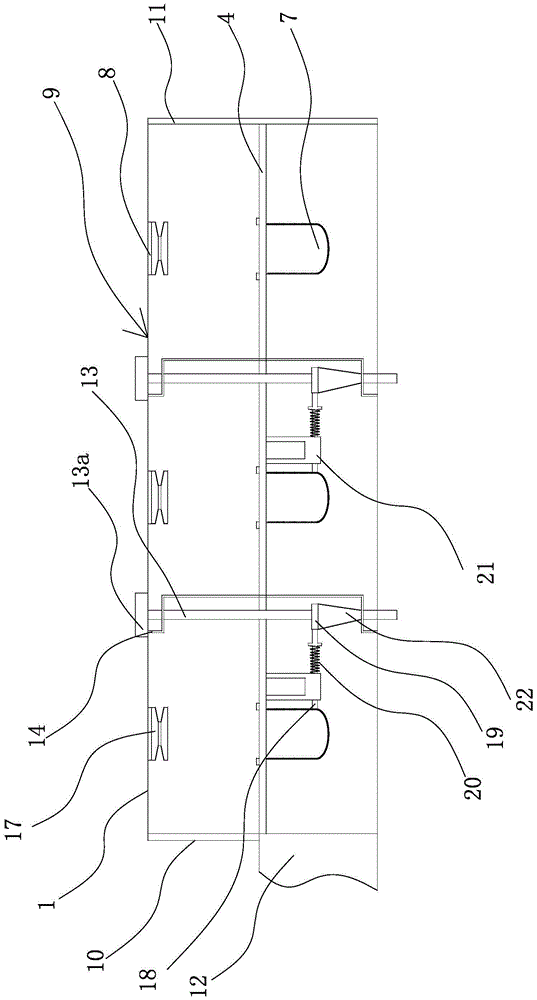

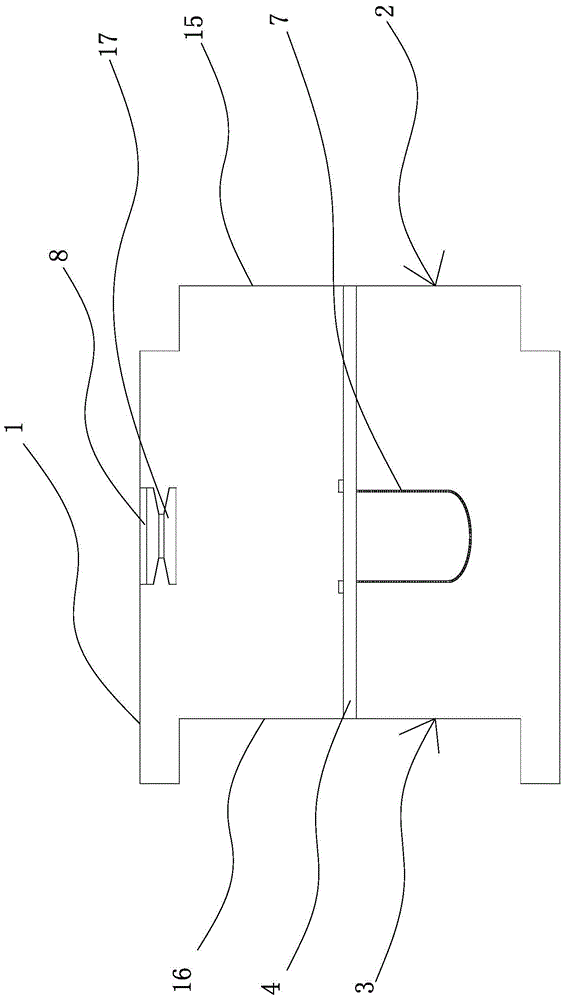

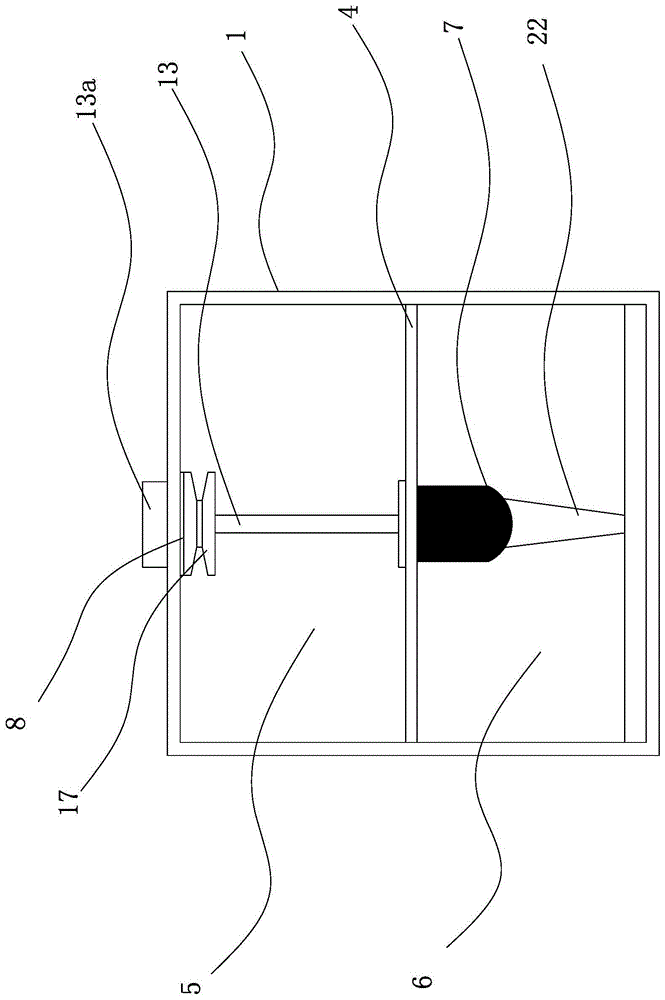

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a series dust collector includes at least two housings 1, the two ends of the housing 1 are open connection end one 2 and connection end two 3, each housing 1 is fixedly connected with a partition 4 , the above-mentioned partition 4 divides the housing 1 into two adjacent cavities up and down: an upper cavity 5 and a lower cavity 6, and a dust bag 7 is fixedly connected to the partition 4, and the belt in the above-mentioned upper cavity 5 The dust flow can enter the lower cavity 6 through the dust removal bag 7. The upper cavity 5 has an inlet 8, and the above shells 1 are connected in series to form a dust removal pipeline 9. One end of the dust removal pipeline 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com