Locking method of filter cylinder

A filter cylinder and tool body technology, applied in hand-held tools, manufacturing tools, etc., can solve the problems of limited space, inconvenient operation, laborious and other problems, and achieve the effect of convenient locking and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

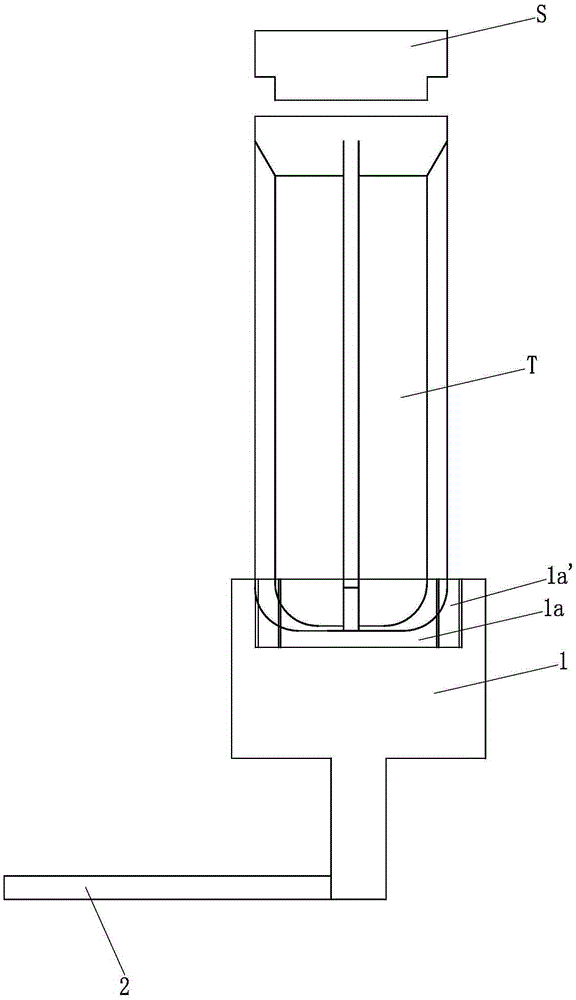

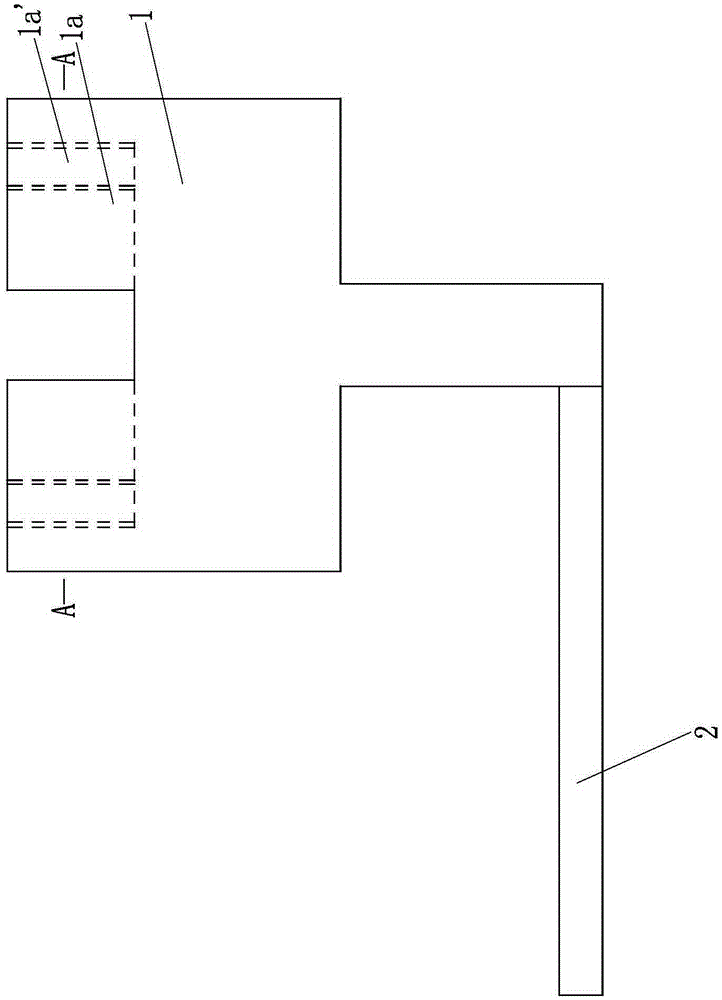

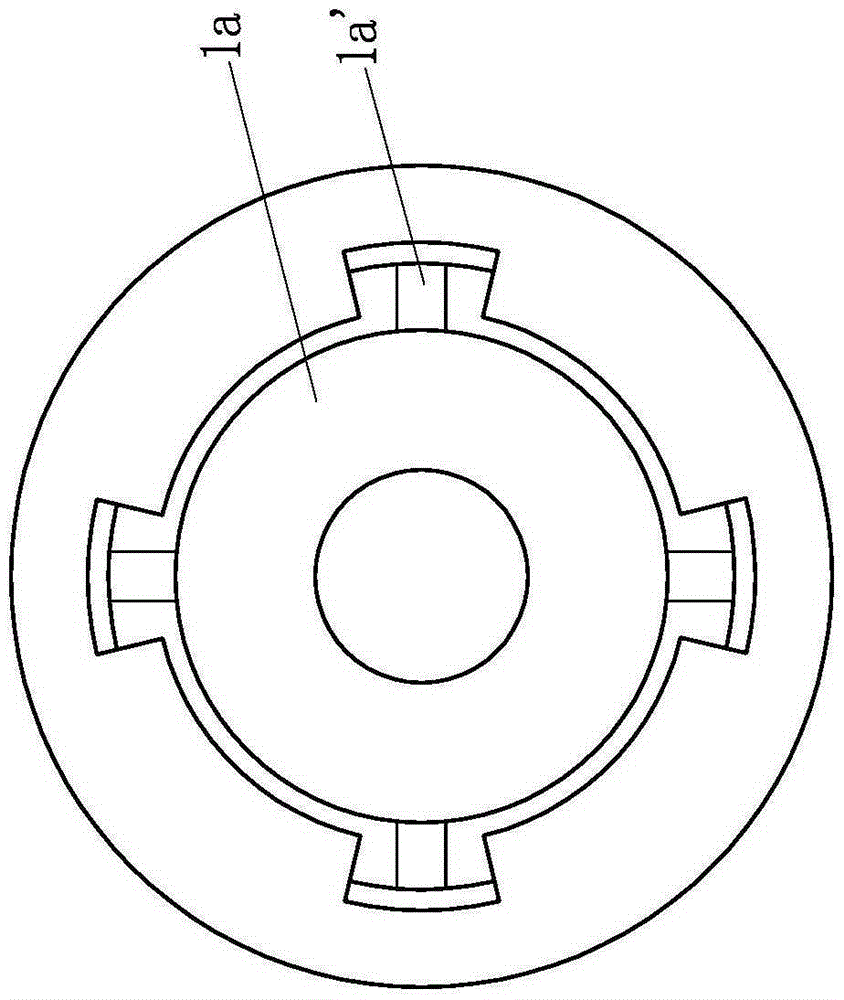

[0019] like figure 1 , 2 And shown in 3, a kind of locking method of filter core cylinder is characterized in that comprising the following steps:

[0020] Step a: first fix the upper cover S, and initially screw the upper cover S and the filter element cylinder T together;

[0021] Step b: Select a locking tool of corresponding size and specification. The locking tool is composed of a tool body 1 and a rotating rod 2. The tool body 1 is a two-stage stepped shaft structure with a large upper part and a smaller lower part. The bottom surface of the small diameter part A described rotating rod 2 is fixedly arranged, and this rotating rod is perpendicular to the axis line of the tool body 1; the distance from the top surface of the rotating rod 2 to the top surface of the tool body 1 is 7-10mm, and can be further preferably 8, 9, 10mm, and the length of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com