Compound milling cutter

A technology of milling cutter and cutter head, which is applied in the field of compound milling cutters, can solve the problems of easy burrs on cutting edges, low surface roughness of grooves, and increased production costs, etc., to achieve convenient and quick disassembly, facilitate discharge, and ensure smoothness degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

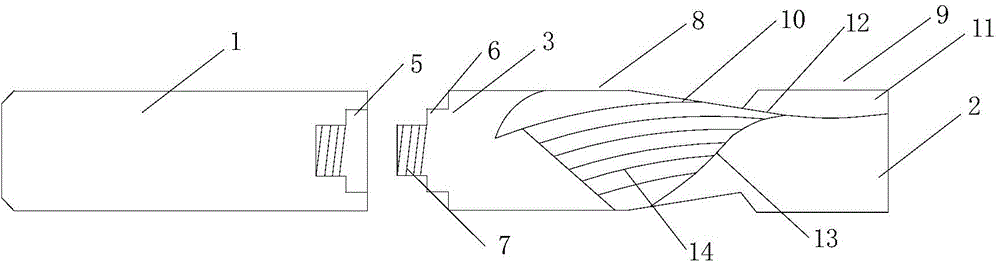

[0014] see figure 1 As shown, the compound milling cutter includes a cylindrical handle 1 and a cutter head part connected to the handle; the cutter head part includes a conical cutter head 2 and a cylindrical connection part 3 affixed to the cutter head The center of the end surface of the handle near the connection part is provided with a groove 4, and the center of the bottom surface of the groove is provided with a screw hole 5; the center of the end surface of the connection part near the connection part is provided with a boss 6 matching the groove , the center of the boss is provided with a screw 7 used in conjunction with the screw hole; the cutter head includes a first cutting portion 8 connected to the connecting portion, a second cutting portion 9 connected to the first cutting portion; the first cutting portion Two helical first cutting edges 10 are arranged on the conical surface; two vertical second cutting edges 11 are oppositely arranged on the conical surface ...

Embodiment 2

[0017] On the basis of Embodiment 1, several fine threads 14 are evenly distributed on the outer surface of the first cutting edge in the same helical direction as the first cutting edge. Since the outer surface of the first cutting edge adopts fine thread, the rigidity of the tool is increased, and it is good to increase the cutting force when processing solid wood or high-density board.

Embodiment 3

[0019] On the basis of Embodiment 1, an arc transition is adopted between the end of the second cutting edge close to the connecting portion and the second cutting portion. Since the second cutting edge is the main cutting edge, the force is relatively large during milling; while the end of the second cutting edge close to the connecting part and the second cutting part adopt a circular arc transition, and there is a support for the second cutting edge Function, can effectively enhance the strength of the second cutting edge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com