Developing box

A developing cartridge and developing roller technology, applied in the field of developing cartridges, can solve the problems of reducing rotational torque, large rotational twisting force, shortening the service life of imaging equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

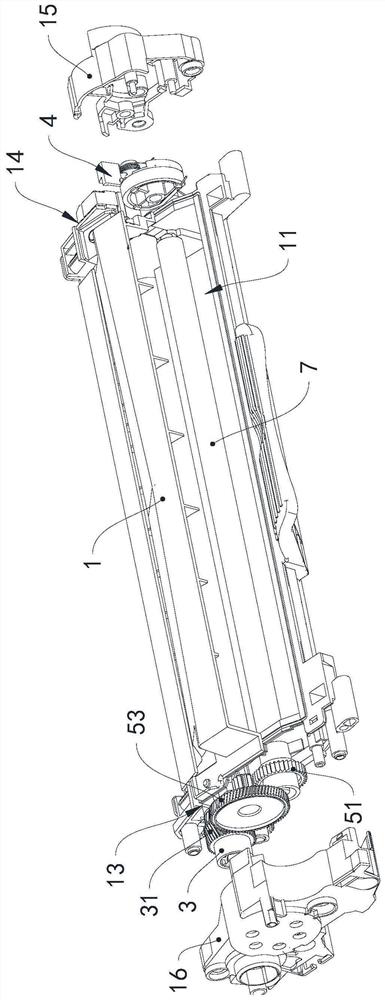

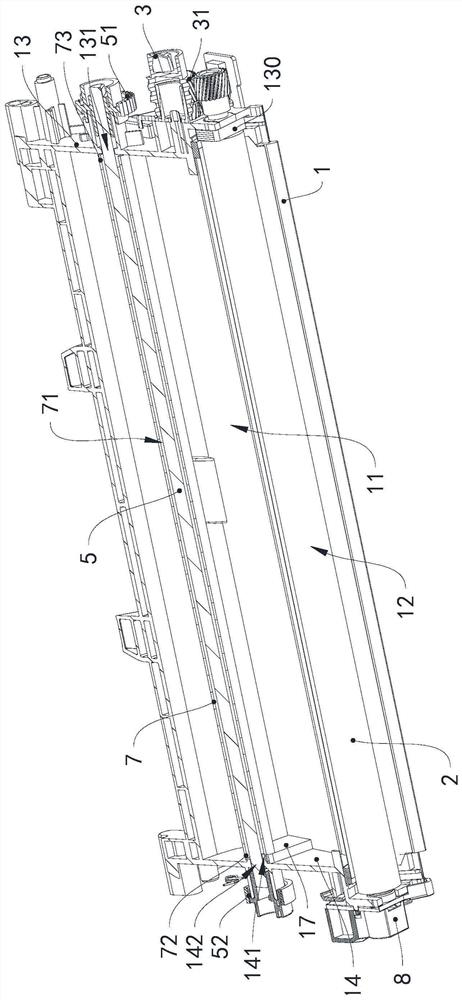

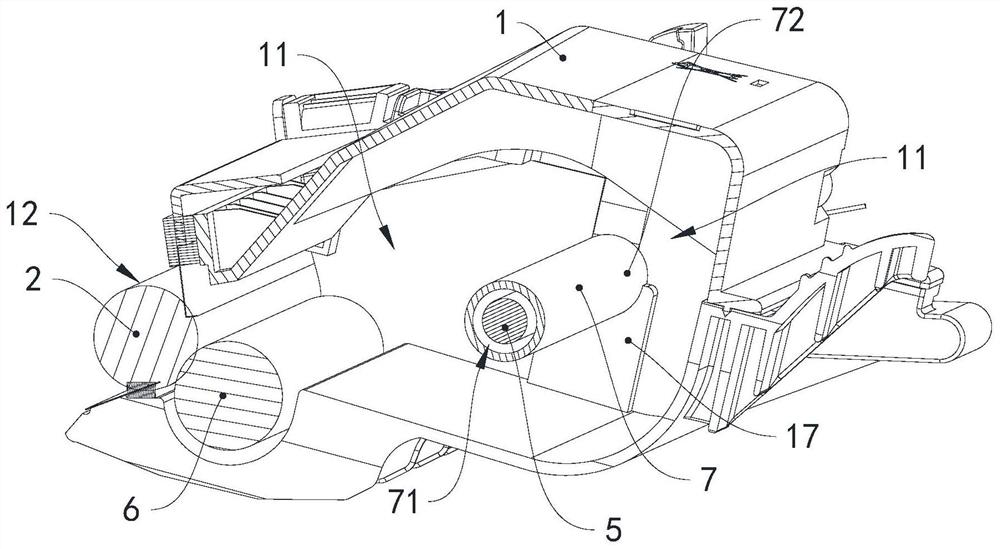

[0026] see Figure 1 to Figure 3 , The developing cartridge in this embodiment includes a box body 1, an end cover 15, an end cover 16, a developing roller 2, a powder feeding roller 6, a driving force receiving head 3, a detection mechanism 4, a transmission shaft 5, a sleeve 7 and conductive components 8.

[0027] The box body 1 has a toner container 11 and a powder outlet 12, the developing roller 2 is rotatably supported at the powder outlet 12, the axial end of the developing roller 2 is provided with a developing roller gear 21, and the powder feeding roller 6 is rotatably Supported in the toner container 11 and adjacent to the developing roller 2, the powder feeding roller 6 is used to transfer the toner in the toner container 11 to the developing roller 2, and the axial end of the powder feeding roller 6 is provided with a powder feeding roller. Roller gear 61.

[0028] The end cover 16 is installed on the first end wall 13, the driving force receiving head 3 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com