Damping device for falling groove of injection molding machine

A shock absorber and injection molding machine technology, applied in the field of injection molding machine accessories, can solve the problems of injection molding machines scattered all over the place, spending a lot of time collecting, product damage, etc., to achieve the effect of avoiding product damage and avoiding product dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

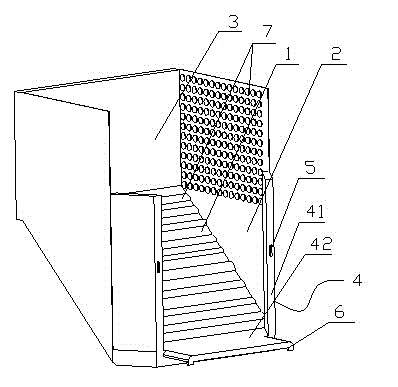

[0009] Such as figure 1 As shown, the preferred embodiment of the present invention is: a kind of injection molding machine drop trough damping device, comprising a slide-type bottom surface 1, side walls 2 arranged on both sides of the slide-type bottom surface 1 and a wall mounted on the upper end of the slide-type bottom surface 1 The vertical baffle 3 also includes a folding device 4, the folding device 4 includes two side baffles 41 connected to the side wall 2 and inclined inwardly, and a straight bottom plate connected to the bottom surface 1 42, a card slot 5 is provided on the front end surface of the two side baffles 41; a buffer rubber 7 is provided on the bottom surface 1 and the side wall 2; the buffer rubber 7 is in the shape of a cylinder or a wave; the A hook 6 is provided at the end of the bottom plate 42 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com