Trapezoid multi-cylinder hydraulic lifting transportation system for mining industry

A technology of hydraulic lifting and transportation system, applied in the direction of hoisting device, hoisting device, etc., can solve the problems of large amount of ore conveyed, high transportation cost, energy waste, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

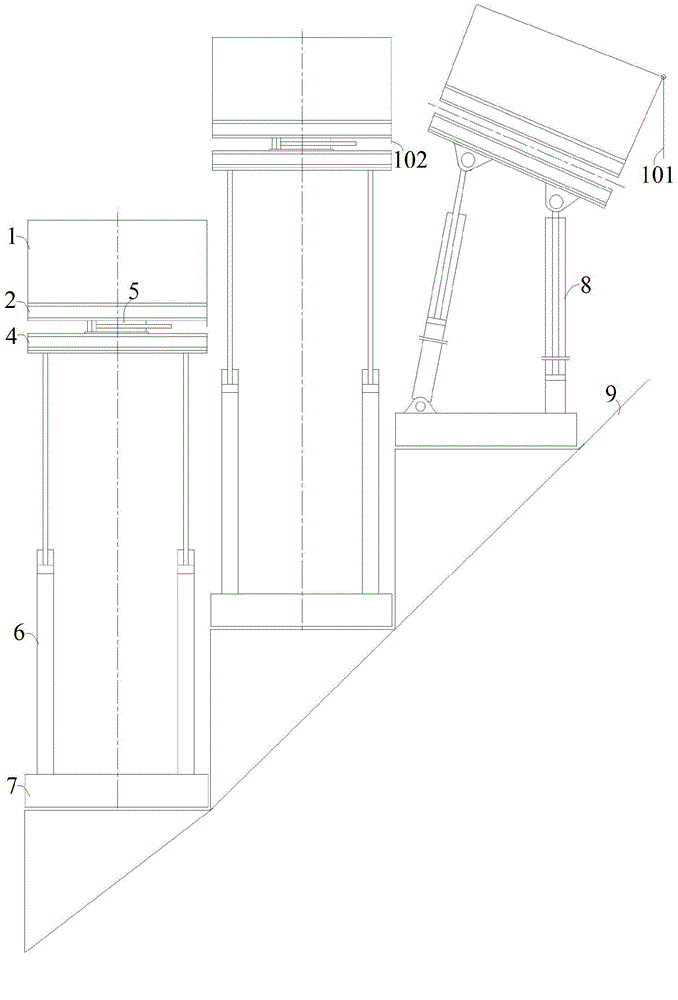

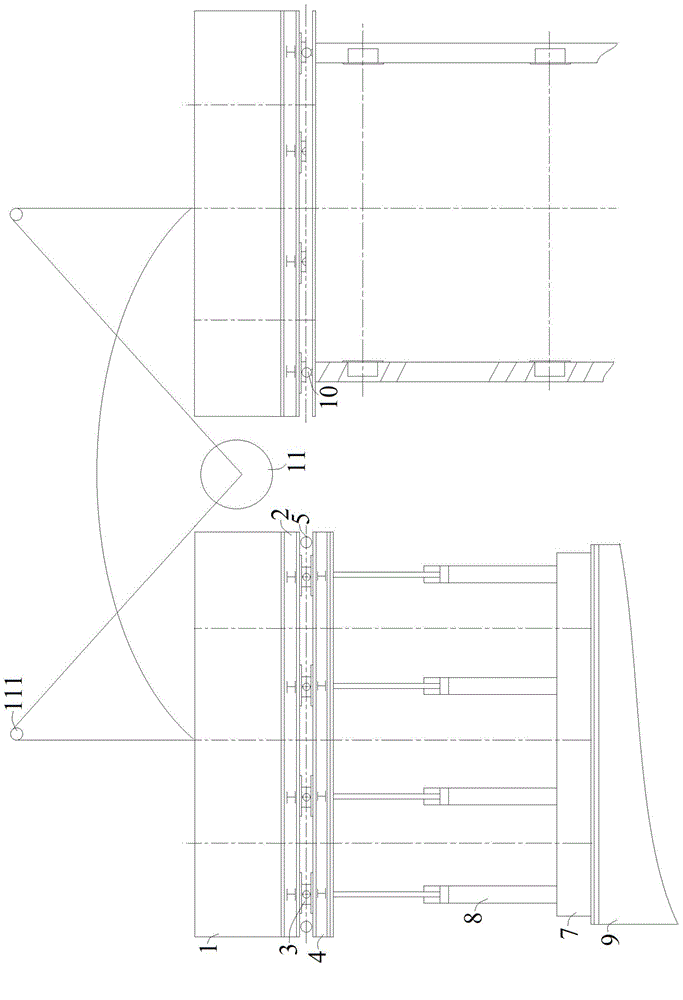

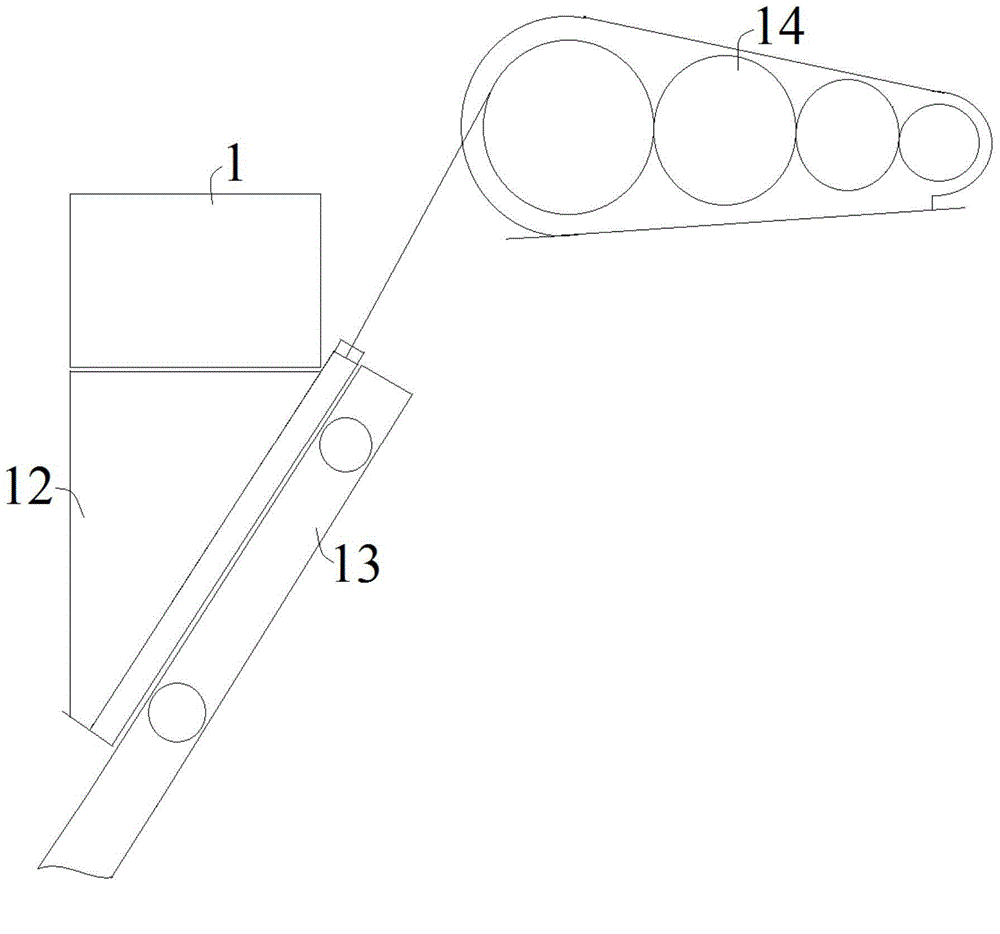

[0032] A mining trapezoidal multi-cylinder hydraulic lift transportation system in this embodiment includes an N-level uplink transportation unit, a material box transfer mechanism and a downlink mechanism. see figure 1 , the N-level transportation unit of this embodiment is built on the slope 9, and a stepped construction platform is built on the slope 9. There is a concrete base 7 on the construction platform, and there is a certain elevation difference between each construction platform. Specifically, the construction platform of this embodiment The elevation difference between is 3 meters, and the transportation unit of present embodiment builds according to slope 9, and the inclination angle of slope 9 can reach 56 °, with respect to traditional automobile transport, the inclination angle of slope promptly needs to build road surface (road surface widening, road surface widening, The steep slope becomes gentle), and the slope inclines up to 56°, which will cost a lot of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com