A method for preparing cuprous oxide microcrystals using carbon quantum dots as a reducing agent

A carbon quantum dot, cuprous oxide technology, applied in copper oxide/copper hydroxide and other directions, can solve the problem of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

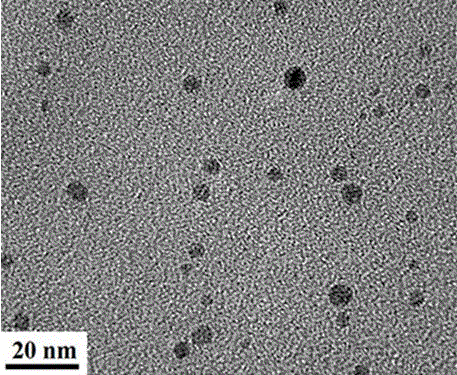

[0021] Example 1 Preparation of carbon quantum dots

[0022] The preparation of carbon quantum dots adopts the hydrothermal synthesis method: weigh 4 g of green grass in a 50 mL polytetrafluoroethylene reactor, then add 20 mL of distilled water, and then place it at 180 o C was kept in a drying oven for 4 h, and the reaction kettle was taken out to cool down to room temperature naturally, and the solid impurities were filtered out to obtain a carbon quantum dot solution.

Embodiment 2

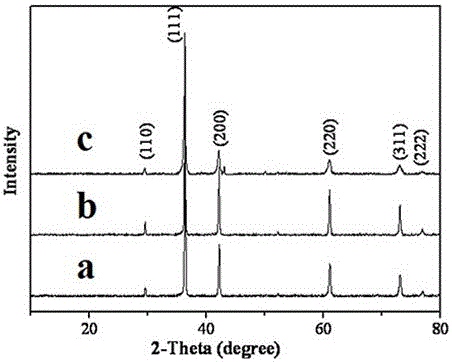

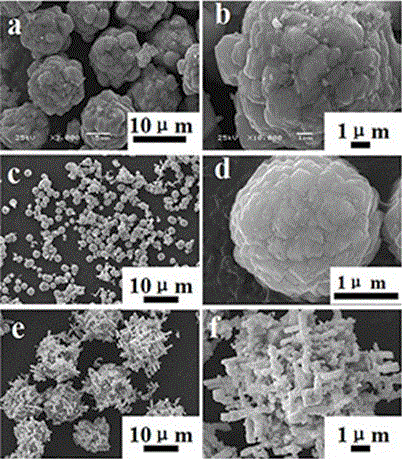

[0023] Example 2 Preparation of Graded Spherical Cuprous Oxide

[0024] 255 mg of Cu(NO 3 ) •3H 2 Dissolve O in 10 mL of distilled water, then add 10 mL of NaOH solution (1 mol / L), add 600 mg of polyethylene glycol 2000 and 8 mL of carbon quantum solution prepared after the dropwise addition, and mix the solution at 1500 r / min Stir for 10 min, then transfer to a 50 mL polytetrafluoroethylene reactor, put in an oven, 180 o C for 8 h, take out the reactor and cool to room temperature naturally; wash the obtained samples with deionized water and absolute ethanol for 3 times, centrifuge and place in a vacuum oven for 60 o C drying for 8 h.

Embodiment 3

[0025] Example 3 Preparation of Spherical Cuprous Oxide

[0026] 255 mg of CuCl 2 • 2H 2 O was dissolved in 10 mL of distilled water, and then 20 mL of NaOH solution (1 mol / L) was added. After the dropwise addition, 800 mg of polyethylene glycol 2000 and 8 mL of the prepared carbon quantum solution were added, and the mixed solution was 100 r / min Stir for 150 min, then transfer to a 50 mL polytetrafluoroethylene reactor, put in an oven, 200 o C for 6 h, take out the reactor and cool it down to room temperature naturally; wash the obtained samples with deionized water and absolute ethanol for 3 times, centrifuge and place them in a vacuum oven for 60 o C drying for 8 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap