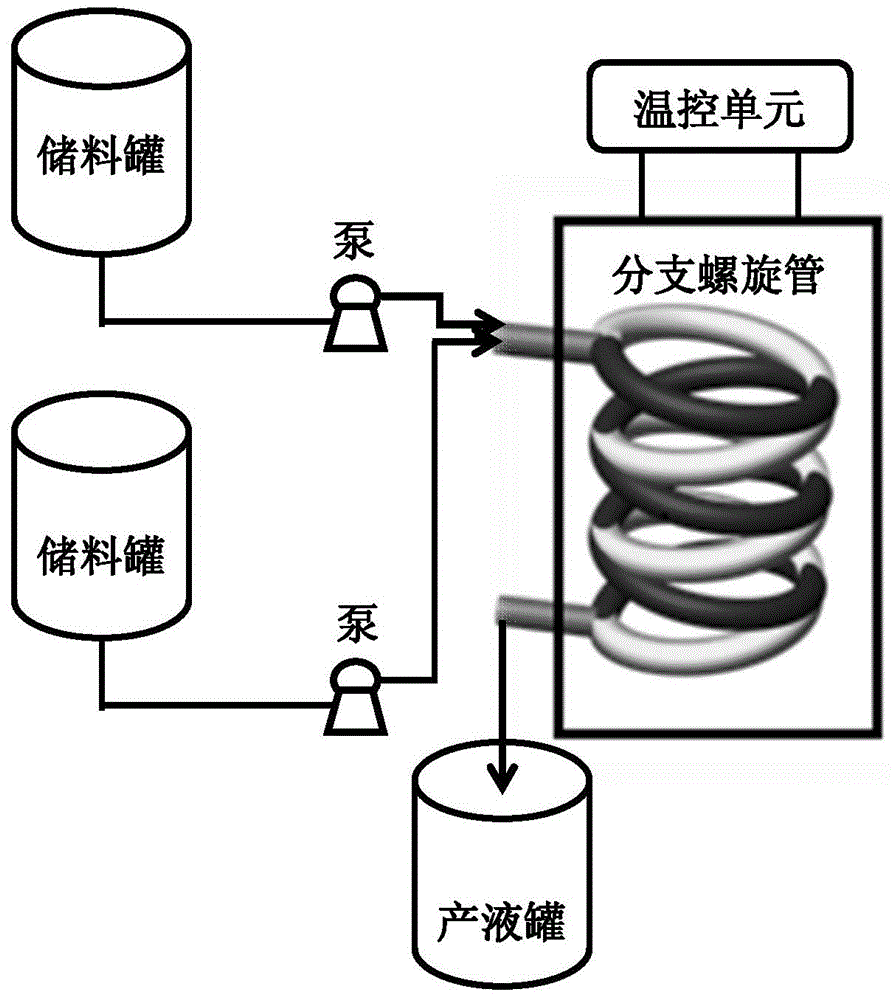

Method for continuously preparing azo pigment in branch spiral tube

A technology of branched spiral tubes and azo pigments, which is applied in the direction of azo dyes, monoazo dyes, chemical instruments and methods, etc., can solve the problems of continuous reaction in reactors with no branched helical structure, and achieve broad industrialization prospects, The effect of high tinting strength and high quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

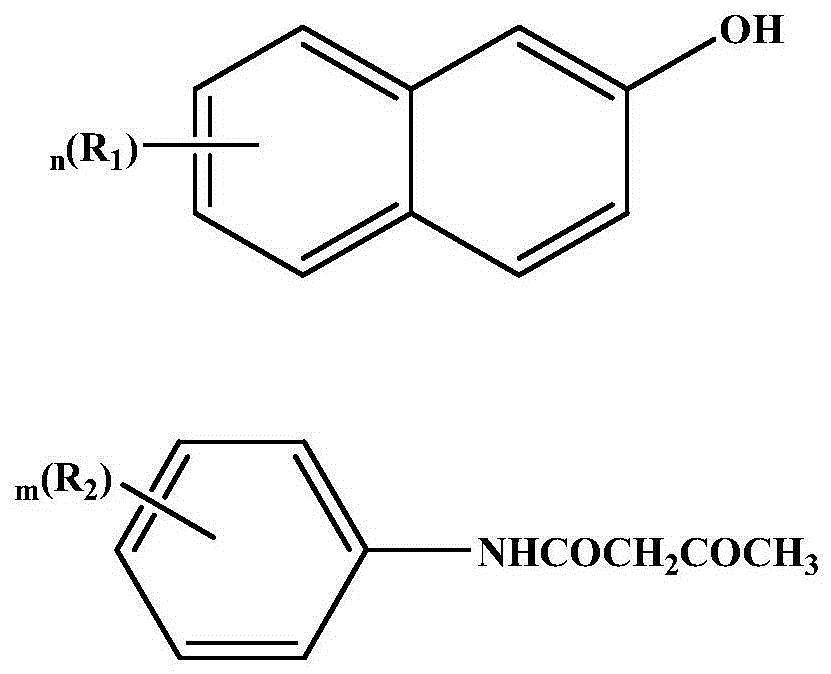

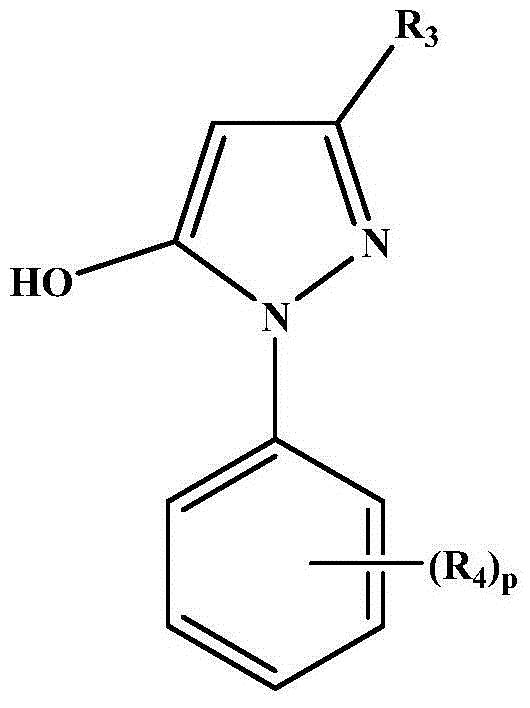

[0032] Example 1 Preparation of Fast Yellow 5GX (C.I.Pigment Yellow 74)

[0033] (1) Continuous method for preparing diazonium salt

[0034] In a 500ml beaker, add 200ml of water, 16.8g of 2-methoxy-4-nitroaniline and 25ml of 37% concentrated hydrochloric acid in sequence, stir until completely dissolved, dilute with water until the total volume of the solution is 250ml, and obtain 2-methoxy Base-4-nitroaniline solution, cooled to 0 °C.

[0035] Add 200ml of water and 7.59g of sodium nitrite successively into a 500ml beaker, stir until the solution is complete, dilute with water until the total volume of the solution is 250ml to obtain a sodium nitrite solution, and cool to 0°C.

[0036] Transfer the above-mentioned 2-methoxyl-4-nitroaniline solution and sodium nitrite solution to two storage tanks respectively, and use a calibrated peristaltic pump to adjust the 2-methoxyl-4-nitroaniline solution and sodium nitrite solution. The flow rate of sodium nitrate solution is 1ml / m...

Embodiment 2

[0040] Embodiment 2 prepares permanent orange GR (C.I.Pigment Orange 18)

[0041] (1) Continuous method for preparing diazonium salt

[0042] Add 150ml of ice water, 9.5ml of aniline and 25ml of 37% concentrated hydrochloric acid successively into a 500ml beaker, stir until completely dissolved, add water to make up the total volume of the solution to 250ml, and prepare aniline solution, and cool to 0°C.

[0043] Add 200ml of ice water and 7.5g of sodium nitrite successively into a 500ml beaker, stir until the solution is complete, add water to dilute until the total volume of the solution is 250ml, to obtain a sodium nitrite solution, and cool to 0°C.

[0044] Transfer the above-mentioned aniline solution and sodium nitrite solution to two storage tanks respectively, use a calibrated peristaltic pump to adjust the flow rate of the aniline solution and sodium nitrite solution to 20ml / min, and transport the two reactants to the branch Spiral tube reactor (the number of branch ...

Embodiment 3

[0051] Embodiment 3 prepares toluidine red (C.I.Pigment Red 3)

[0052] (1) Ordinary diazotization reaction

[0053] 200ml of water, 15g of 4-methyl-2-nitroaniline and 25ml of 37% hydrochloric acid were successively added to a 500ml beaker, and the mixture was cooled to 0-5°C using an ice-water bath. Add 30ml of 25% sodium nitrite solution at this temperature, and continue to stir at 0°C for more than half an hour, add sulfamic acid to remove excess sodium nitrite. Dilute with water until the total volume of the solution is 500ml to obtain a diazonium salt solution.

[0054] (2) Continuous coupling reaction

[0055] In a 500ml beaker, add 300ml of water, 14.5g of 2-naphthol and 10g of sodium hydroxide successively, stir until dissolved, then add 50mL of 37% hydrochloric acid solution, 2-naphthol is suspended in the solution, and then add 10g of carbonic acid Sodium, dilute with water until the total volume of the solution is 500ml.

[0056] Transfer the 4-methyl-2-nitroani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com