Serial preparation method of cladding azo pigment in branch spiral pipe

A technology of branched spiral tubes and azo pigments, applied in the direction of azo dyes, monoazo dyes, chemical instruments and methods, etc., to achieve the effect of easy to become unstable, small particle size, and broad industrialization prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

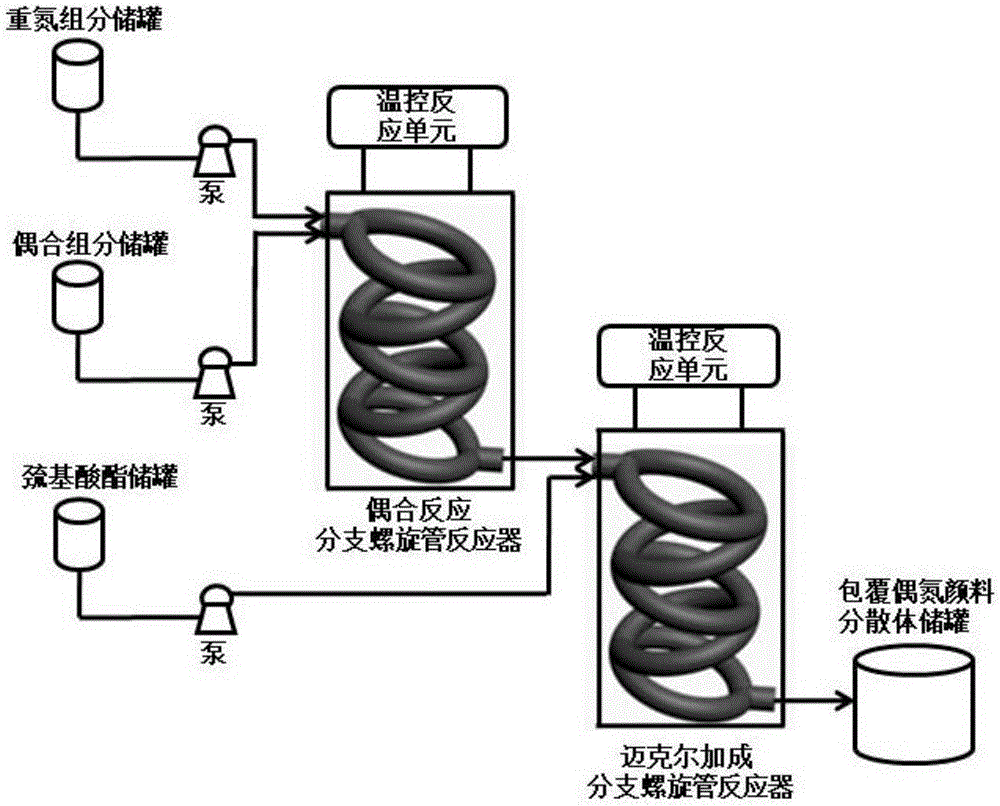

Method used

Image

Examples

Embodiment 1

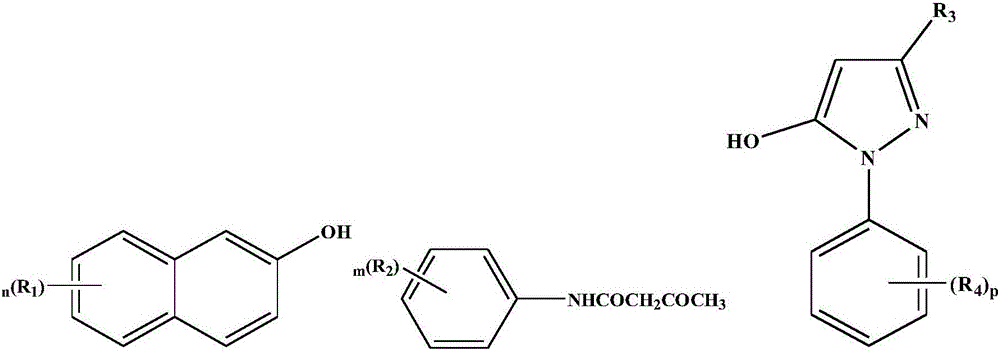

[0039] Example 1 Preparation of Coated Sunfast Yellow 5GX (C.I.Pigment Yellow 74)

[0040] Step 1: Preparation of Coupling Component Solution:

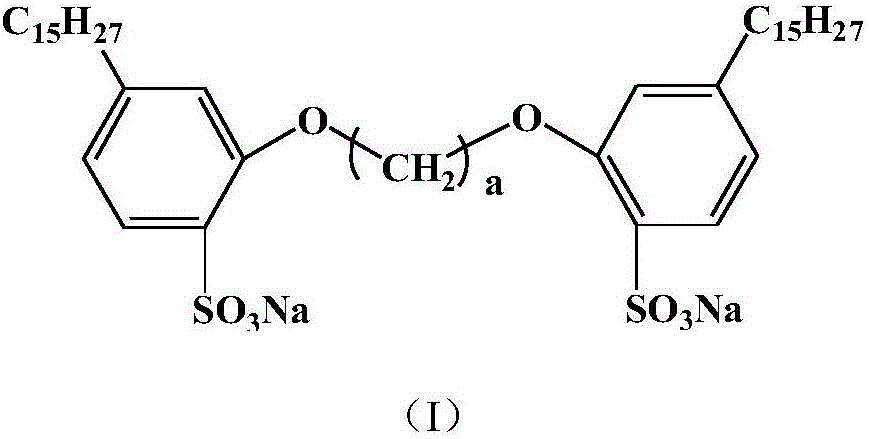

[0041]Add 20.7g o-methoxy acetoacetanilide and 400ml water in 800ml beaker, then add 2.07g cardanol base gemini surfactant as shown in formula (III), add 10.6g sodium carbonate again, stir, add water again dilute When the total volume of the solution is 500ml, a coupling component solution is obtained.

[0042] Step 2: Preparation of diazonium salt solution: prepare 2-methoxy-4-nitroaniline diazonium salt solution with the same molar concentration as the coupling component solution for later use.

[0043]

[0044] Step 3: Coupling reaction: transfer the 2-methoxy-4-nitroaniline diazonium salt solution and the o-methoxyacetoacetanilide solution to the storage tanks of the diazo component and the coupling component respectively, and use the calibrated peristaltic Pump, adjust the flow rate of the diazo component solution and the co...

Embodiment 2

[0047] Example 2 Preparation of coated toluidine red (C.I.Pigment Red 3)

[0048] Step 1: Preparation of Coupling Component Solution:

[0049] Add 300ml of water, 14.5g of 2-naphthol and 10g of sodium hydroxide successively in a 500ml beaker, stir until dissolved, then add 50mL of 37% hydrochloric acid solution, 2-naphthol is suspended in the solution, and then 2.9g of The cardanol-based gemini surfactant shown in formula IV, and add 10g sodium carbonate, add water and dilute to solution total volume and be 500ml.

[0050] Step 2: Preparation of diazonium salt solution: prepare 4-methyl-2-nitroaniline diazonium salt solution with the same molar concentration as the coupling component solution for later use.

[0051]

[0052] Step 3: Coupling reaction: transfer the 4-methyl-2-nitroaniline diazonium salt solution and the 2-naphthol suspension to the storage tanks of the diazo component and the coupling component respectively, and use a calibrated peristaltic pump to adjust ...

Embodiment 3

[0055] Example 3 Preparation of coated permanent yellow NCG (C.I.Pigment Yellow 16)

[0056] Step 1: Preparation of Coupling Component Solution:

[0057] In a 1L beaker, add 800ml of water, 38g 3,3'-dimethylbisacetoacetylbenzidine and 10g of sodium hydroxide successively, and stir. Then add 5.7g of cardanol-based gemini surfactant shown in formula III and 35ml of 30% sodium hydroxide solution, quickly add 50ml of glacial acetic acid, and 3,3'-dimethylbisacetoacetylbenzidine is suspended in Solution, add water to dilute to a total solution volume of 1000ml.

[0058] Step 2: Preparation of diazonium salt solution: prepare 2,5-dichloroaniline diazonium salt solution with the same molar concentration as the coupling component solution for later use.

[0059] Step 3: Coupling reaction: transfer the 2,5-dichloroaniline diazonium salt solution and the 3,3'-dimethylbisacetoacetylbenzidine suspension to the storage tanks of the diazo component and the coupling component respectively,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com