Reverse stop bearing with anti-wedge reverse bearing retainer

A bearing retainer and stop bearing technology, which is applied to bearing elements, shafts, bearings, clutches, etc., can solve the problems of one-way failure of bearing rings, affecting product quality, and two-way jamming, so as to prevent wedges from being reversed. , Simple structure, the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific drawings and embodiments.

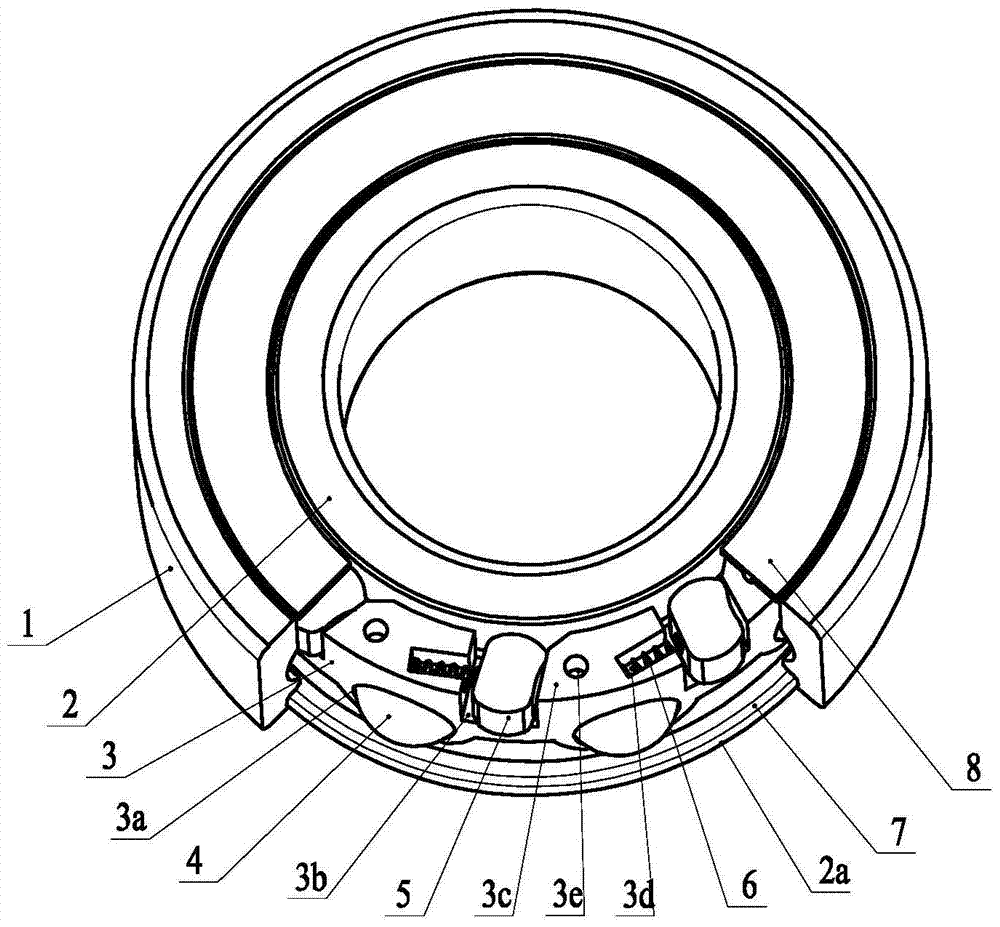

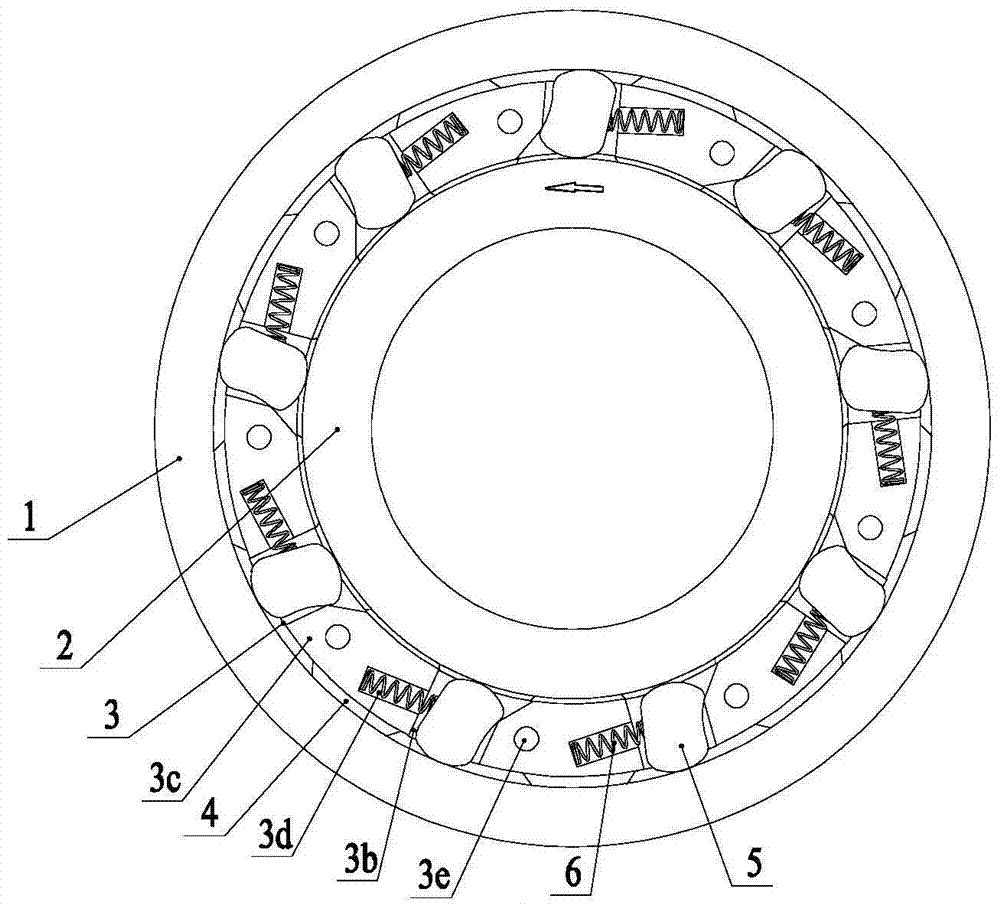

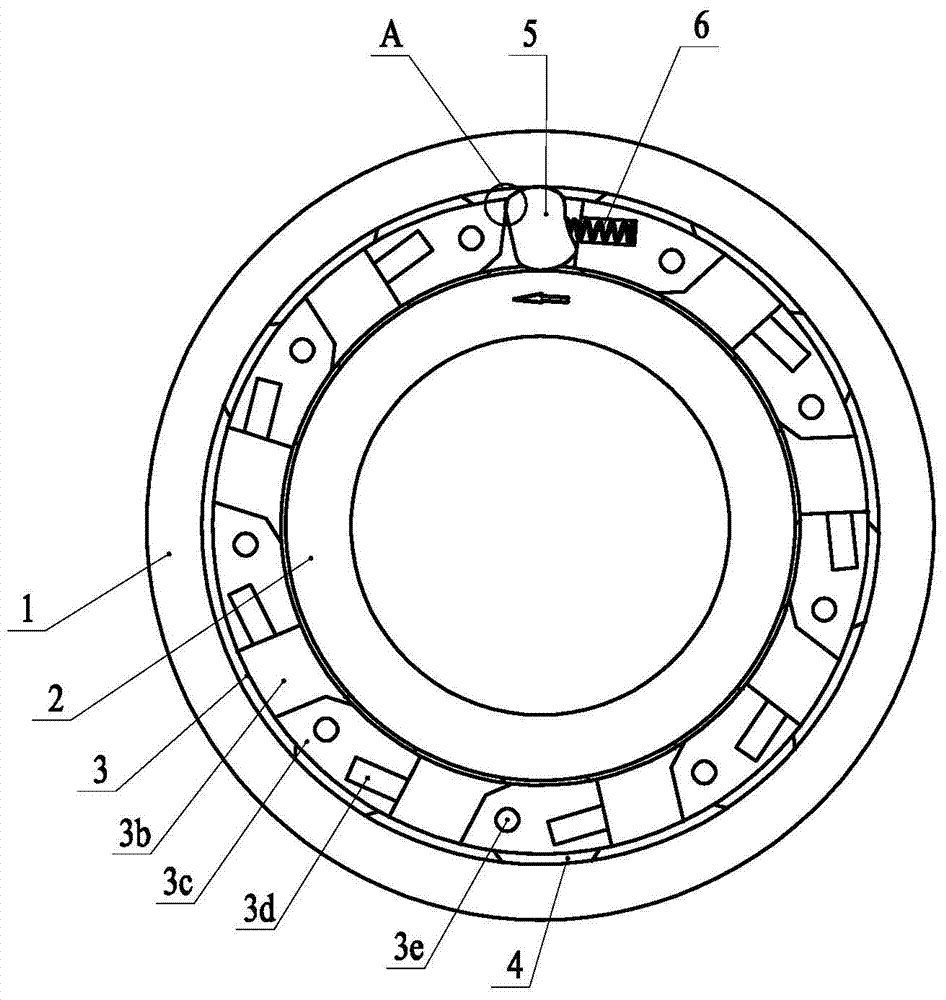

[0017] As shown in the figure, the reverse stop bearing with anti-wedge anti-installation bearing retainer in the embodiment is mainly composed of outer ring 1, inner ring 2, retainer body 3, steel ball 4, wedge 5, compression spring 6, The sealing ring 7 and the fixed cover 8 are formed.

[0018] like Figure 1~Figure 4 As shown, the cage body 3 is arranged between the outer ring 1 and the inner ring 2, and nine ball pockets 3a uniformly distributed in the circumferential direction are arranged on the circumferential surface of the cage body 3, and each ball pocket 3a is equipped with a steel ball 4 ; The first end face of the retainer body 3 is provided with nine circumferentially evenly distributed wedge notches 3b, each wedge notch 3b is equipped with a wedge 5, and between adjacent wedge notches 3b is The wedges are spaced from the boss 3c; the fixed cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com