Tire pressure sensor package lead frame

A tire pressure sensor and packaging lead technology, which is applied in the direction of electric solid-state devices, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of complicated chip process, difficult chip installation, and complicated lead frame manufacturing process, etc. The effects of electrical and thermal conductivity, good oxidation resistance and corrosion resistance, and good thermal matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

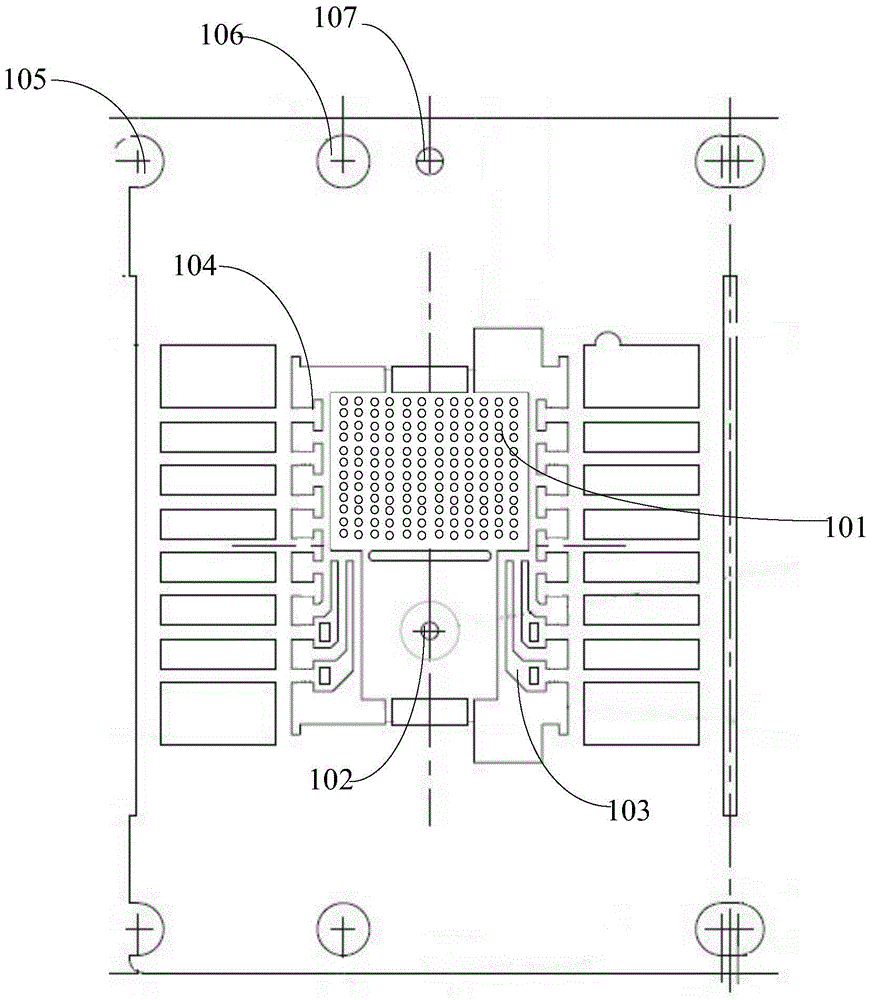

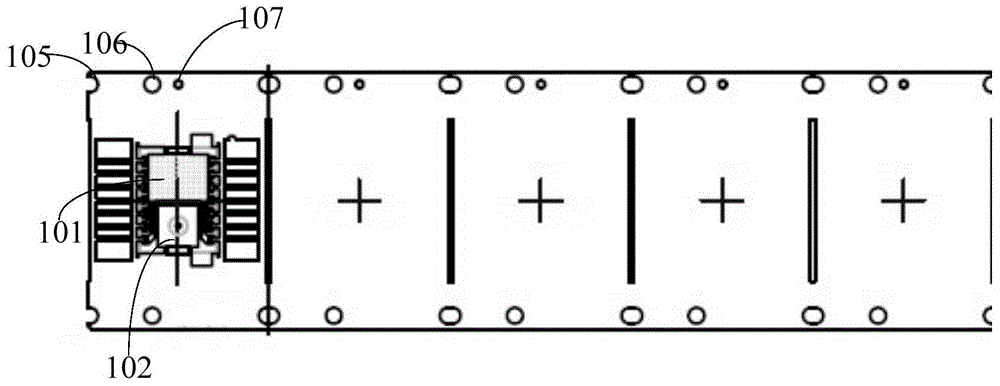

[0019] Such as figure 1 Shown is a structural schematic diagram of the tire pressure sensor packaging lead frame.

[0020] A tire pressure sensor packaging lead frame is used for fixedly connecting a tire pressure sensor chip, a main control chip and a transmitting chip; it includes a frame body, and the frame body is made of nickel-palladium-gold material.

[0021] The frame body includes a first base island 101, a second base island 102, a first lead wire 104 and a second lead wire 103; the first base island 101 and the second base island 102 are arranged on the The center of the frame body; the first base island 101 is used to install the main control chip and the emitting chip; the second base island 102 is provided with a through hole in the center, and the through hole is used to sense the external air pressure. The second base island 102 is used to fix the tire pressure sensor chip; the first lead line 104 is T-shaped, and the first lead line 104 is arranged on opposit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com